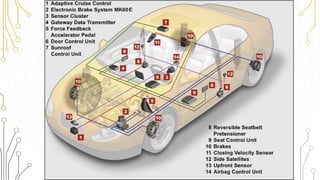

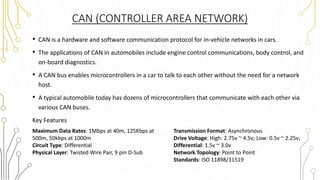

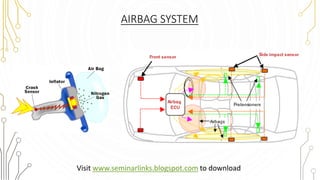

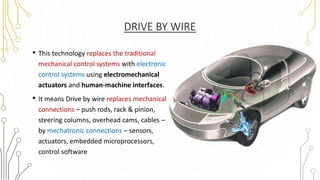

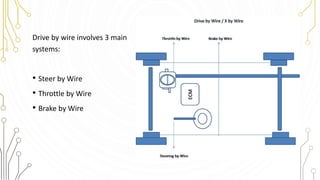

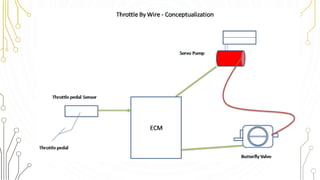

The document discusses embedded systems in automobiles, which combine hardware and software to control various functions, including airbags and traction control. It highlights the importance of real-time operation, low cost, and quick response in these systems, alongside the role of the Controller Area Network (CAN) for communication between microcontrollers. The text concludes by emphasizing the shift from mechanical to electronic systems in modern vehicles and the need for attention to safety and security in automotive embedded system design.