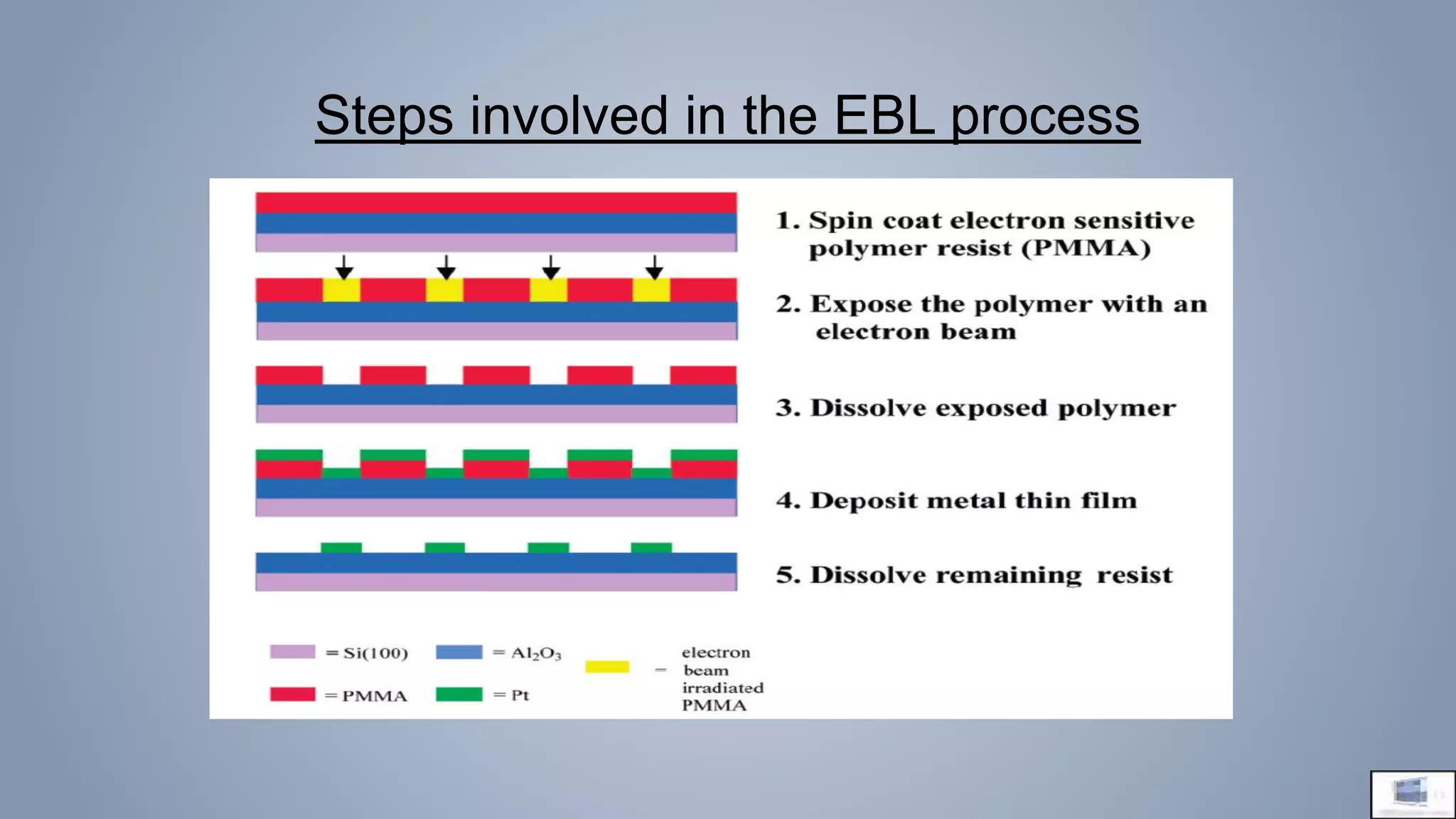

Electron beam lithography uses a focused beam of electrons to directly write nanoscale patterns onto a resist-coated surface. It allows for very high resolution patterning down to a few nanometers in size. The process involves coating a surface with an electron-sensitive resist, using a focused electron beam to expose patterns in the resist according to design data, and then developing the resist to selectively remove the exposed or unexposed areas. Key advantages of electron beam lithography include its lack of diffraction limit on resolution and ability to create specialized device structures. However, it also has disadvantages like long write times and high system costs.