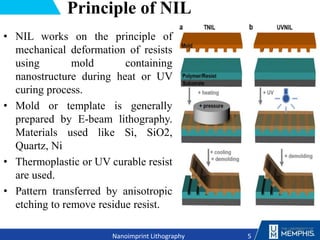

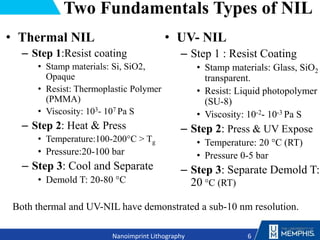

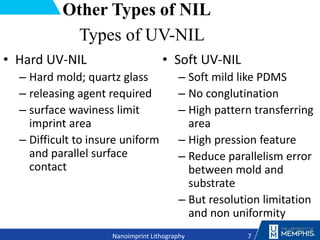

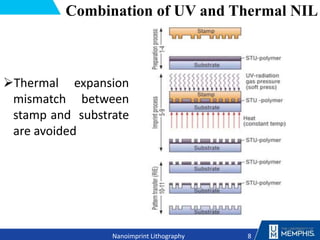

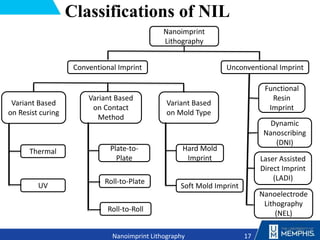

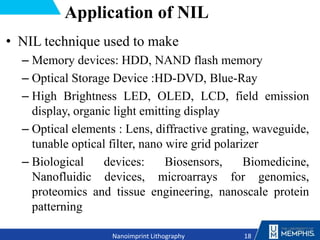

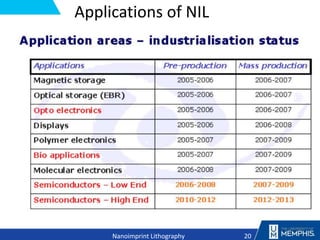

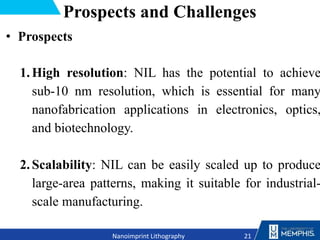

The document discusses nanoimprint lithography (NIL), a nanofabrication technique that allows for high-resolution patterning using a mold or template. It outlines the history and principles of NIL, describes common types including thermal and UV NIL, and lists applications such as memory devices, optics, and biotechnology. The document also examines prospects such as high resolution and scalability but also challenges involving template fabrication and large-area patterning uniformity. In conclusion, NIL is presented as a promising low-cost technique for nanofabrication if current challenges can be addressed.

![References

1. Lan H, Ding Y. Nanoimprint Lithography. In: Lithography. InTech.

2. Resnick D. Nanoimprint lithography. In: Nanolithography: The Art of Fabricating Nanoelectronic and Nanophotonic Devices and Systems. Elsevier Ltd,

2013, p. 315–347.

3. Chou S. Nanoimprint lithography. Technol Rev 106: 42, 2003.

4. Chou SY, Krauss PR, Renstrom PJ. Imprint of sub-25 nm vias and trenches in polymers. Appl Phys Lett 67: 3114, 1995. doi: 10.1063/1.114851.

5. Hua F, Sun Y, Gaur A, Meitl MA, Bilhaut L, Rotkina L, Wang J, Geil P, Shim M, Rogers JA, Shim A. Polymer imprint lithography with molecular-

scale resolution. Nano Lett 4: 2467–2471, 2004. doi: 10.1021/nl048355u.

6. Handrea-Dragan M, Botiz I. Multifunctional structured platforms: From patterning of polymer-based films to their subsequent filling with various

nanomaterials. Polymers (Basel) 13 MDPI AG: 1–49, 2021

7. Higashiki T. Nanoimprint lithography and future patterning for semiconductor devices. Journal of Micro/Nanolithography, MEMS, and MOEMS 10:

043008, 2011. doi: 10.1117/1.3658024.

8. Nanoimprint Lithography – YouTube

9. Kehagias N, Reboud V, Chansin G, Zelsmann M, Jeppesen C, Reuther F, Schuster C, Kubenz M, Gruetzner G, Sotomayor Torres CM. Submicron

three-dimensional structures fabricated by reverse contact UV nanoimprint lithography. Journal of Vacuum Science & Technology B: Microelectronics and

Nanometer Structures 24: 3002, 2006. doi: 10.1116/1.2388962.

10. Colburn M, Grot A, Amistoso MN, Choi BJ, Bailey TC, Ekerdt JG, Sreenivasan S V., Hollenhorst J, Willson CG. Step and flash imprint lithography

for sub-100-nm patterning. In: Emerging Lithographic Technologies IV. SPIE, 2000, p. 453–457.

11. Han KS, Hong SH, Lee H. Fabrication of complex nanoscale structures on various substrates. Appl Phys Lett 91, 2007. doi: 10.1063/1.2789735.

12. Chou SY, Keimel C, Gu J. Ultrafast and direct imprint of nanostructures in silicon. Nature 417: 835–837, 2002. doi: 10.1038/nature00792.

13. Lee T, Lee C, Oh DK, Badloe T, Ok JG, Rho J. Scalable and high-throughput top-down manufacturing of optical metasurfaces. Sensors (Switzerland) 20

MDPI AG: 1–33, 2020.

14. Yokoo A, Namatsu H. NTT Technical Review [Online]. https://www.ntt-review.jp/archive/ntttechnical.php?contents=ntr200808sp3.pdf&mode=show_pdf

26

Nanoimprint Lithography](https://image.slidesharecdn.com/nanoimprintlithographyareview-230517211507-5e6bf289/85/Nanoimprint-Lithography-26-320.jpg)