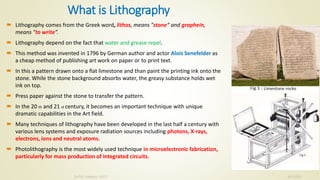

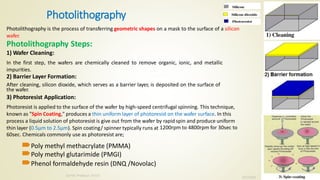

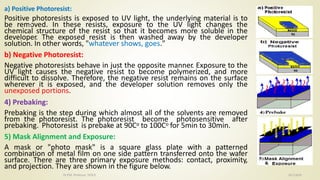

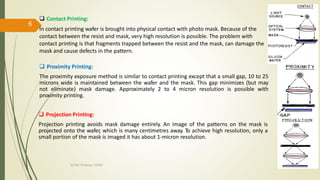

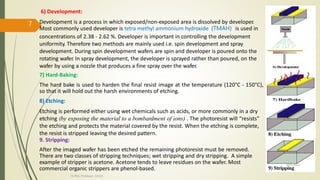

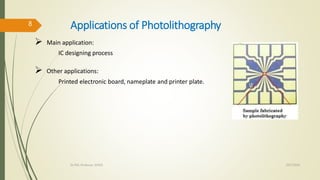

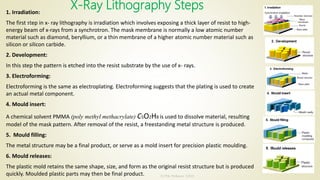

This document outlines Dr. P. Senthilkumar's talk on various lithography techniques. It begins with an introduction to lithography, then discusses specific techniques like photolithography, electron beam lithography, nanolithography, and x-ray lithography. For photolithography, it provides detailed steps including wafer cleaning, photoresist application, exposure, development, and etching. It also discusses applications of lithography in microelectronics fabrication.