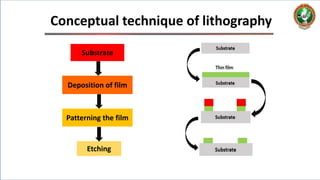

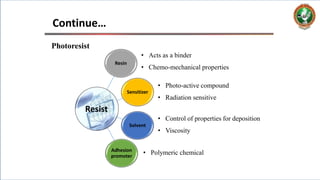

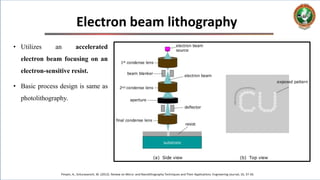

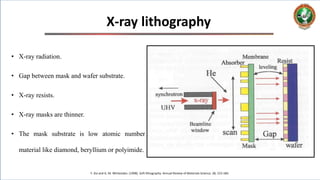

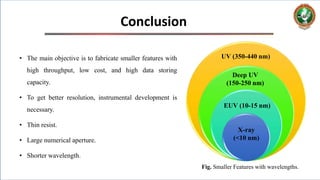

The document discusses various lithography techniques used in microfabrication. It begins with an introduction to lithography, then discusses photolithography, electron beam lithography, and x-ray lithography in more detail. For each technique, it covers the basic conceptual process, advantages, limitations, and applications. Key points are that photolithography allows high-throughput mass production but is limited by diffraction, while electron beam and x-ray lithography can achieve much higher resolution below 10nm without diffraction effects, but have lower throughput. The document concludes that continuing instrumental development toward shorter wavelengths is needed to achieve better resolution for applications requiring smaller feature sizes.