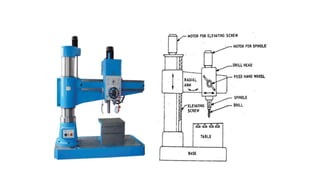

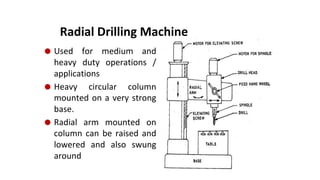

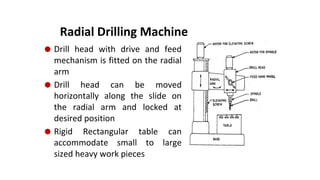

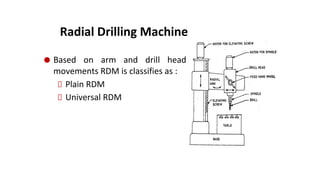

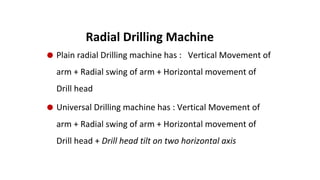

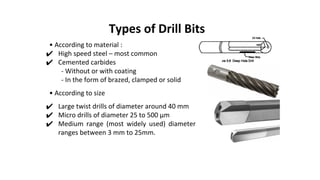

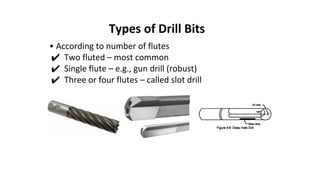

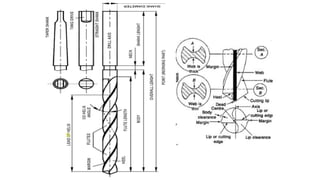

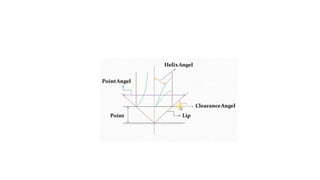

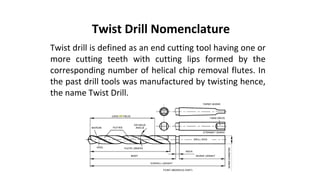

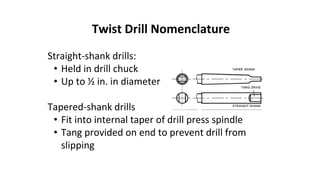

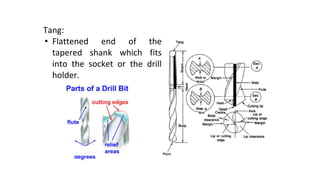

The document discusses radial drilling machines and drill bits. It describes how a radial drilling machine has a heavy circular column mounted on a strong base, with a radial arm that can be raised, lowered, and swung around. The drill head is fitted to the radial arm and can move horizontally and lock in position. Radial drilling machines are classified as plain or universal based on arm and drill head movements. The document also describes different types of drill bits based on material, size, number of flutes, helix angle, length, shank, and specific applications.