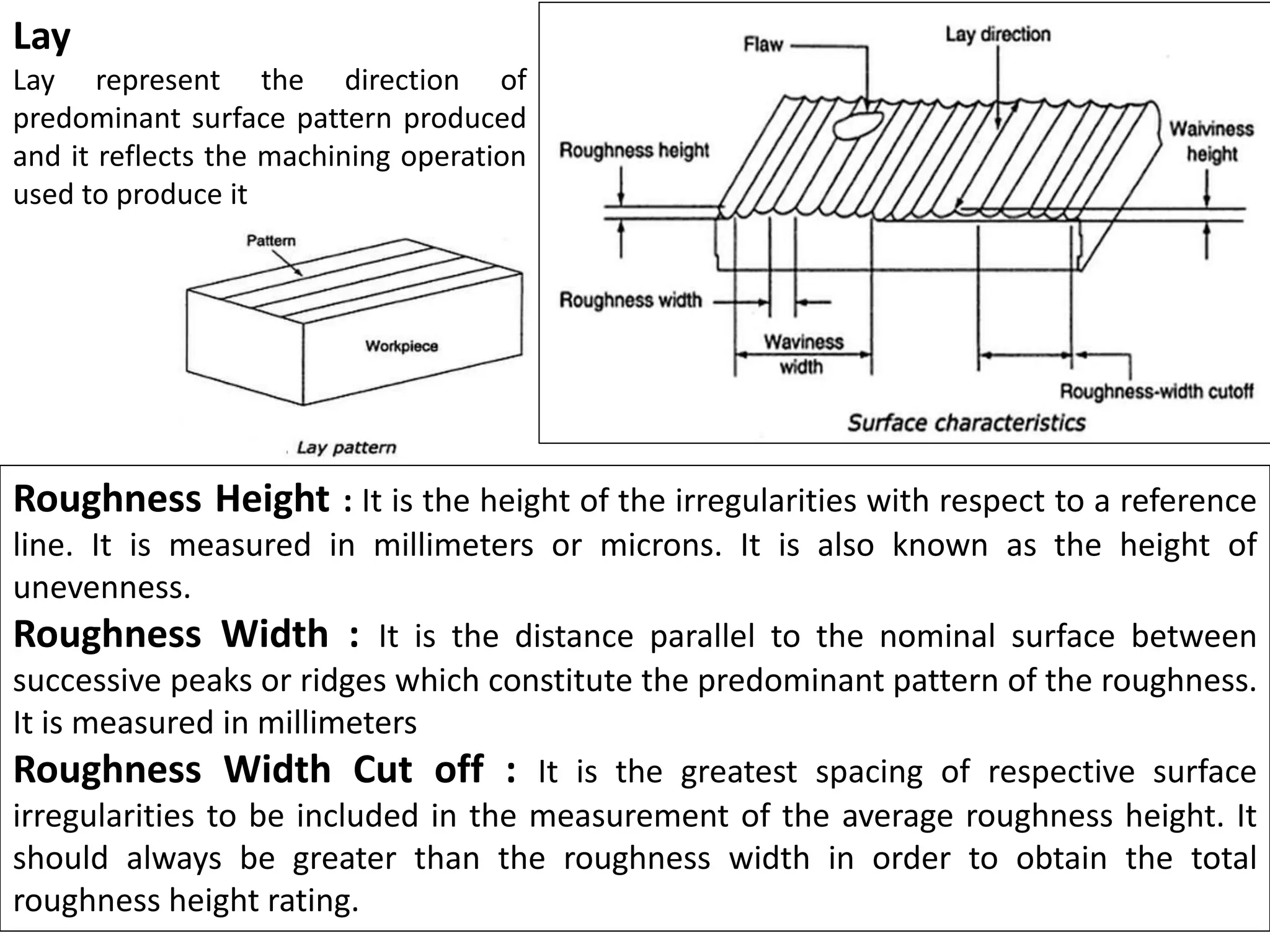

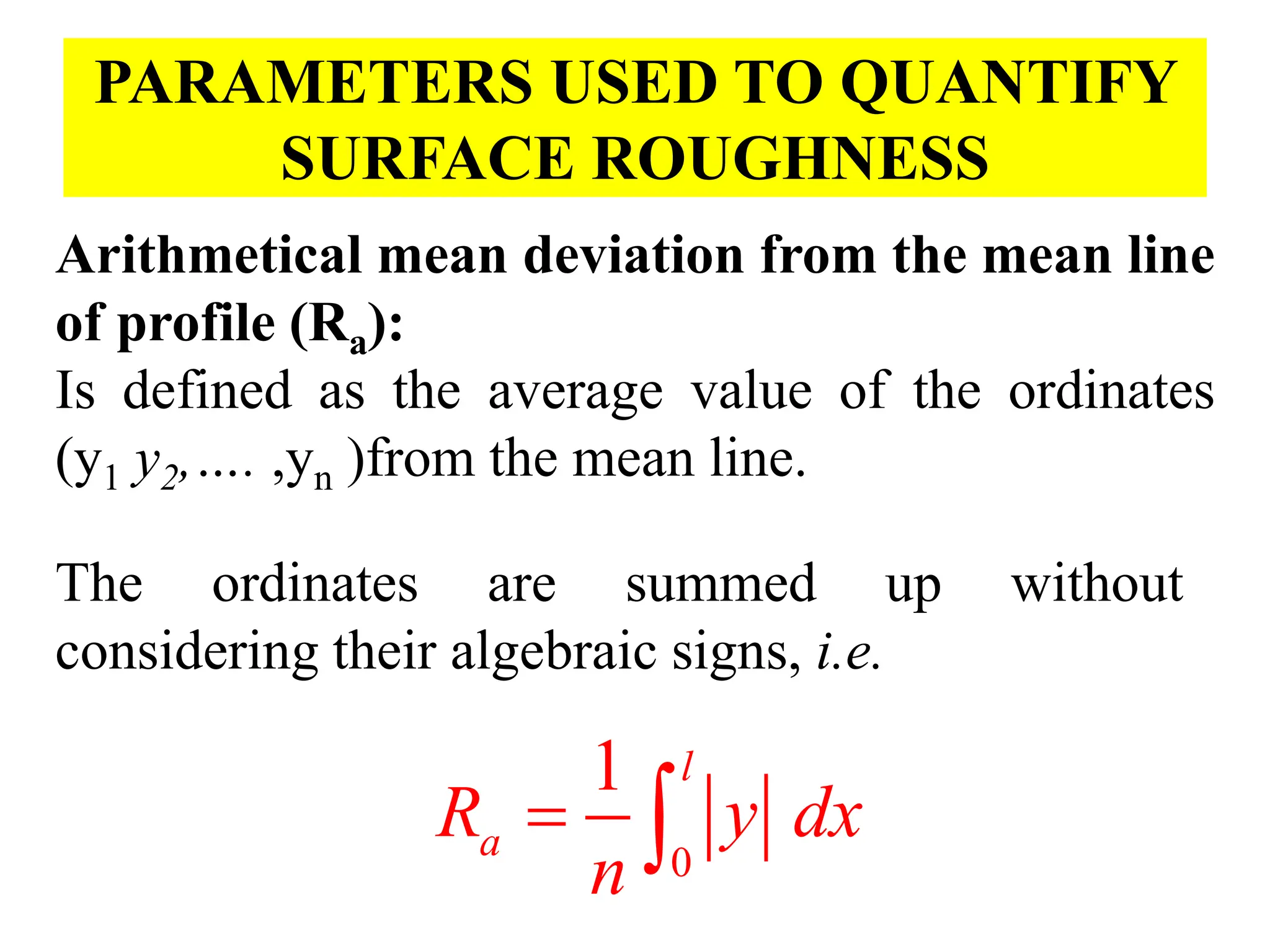

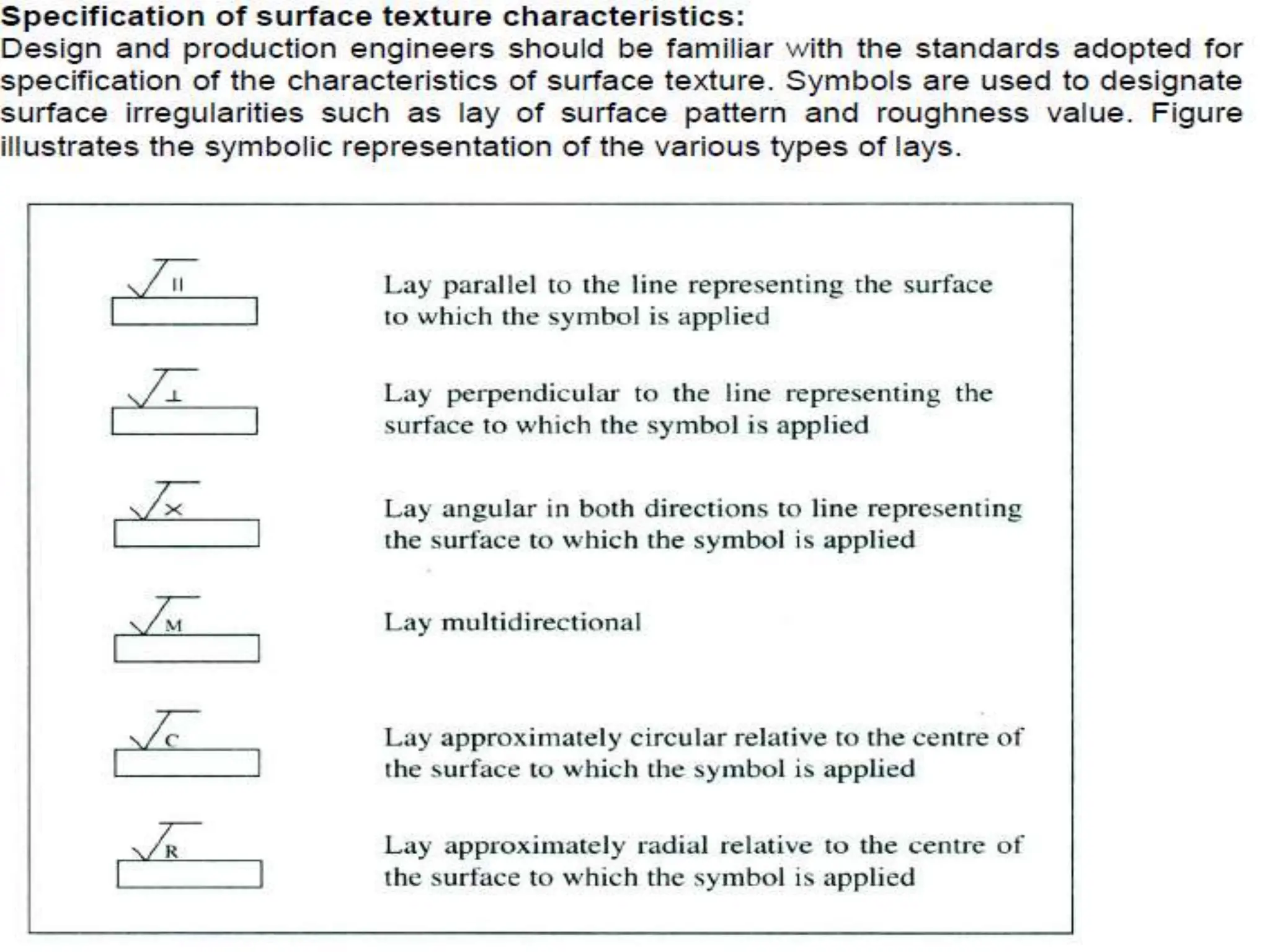

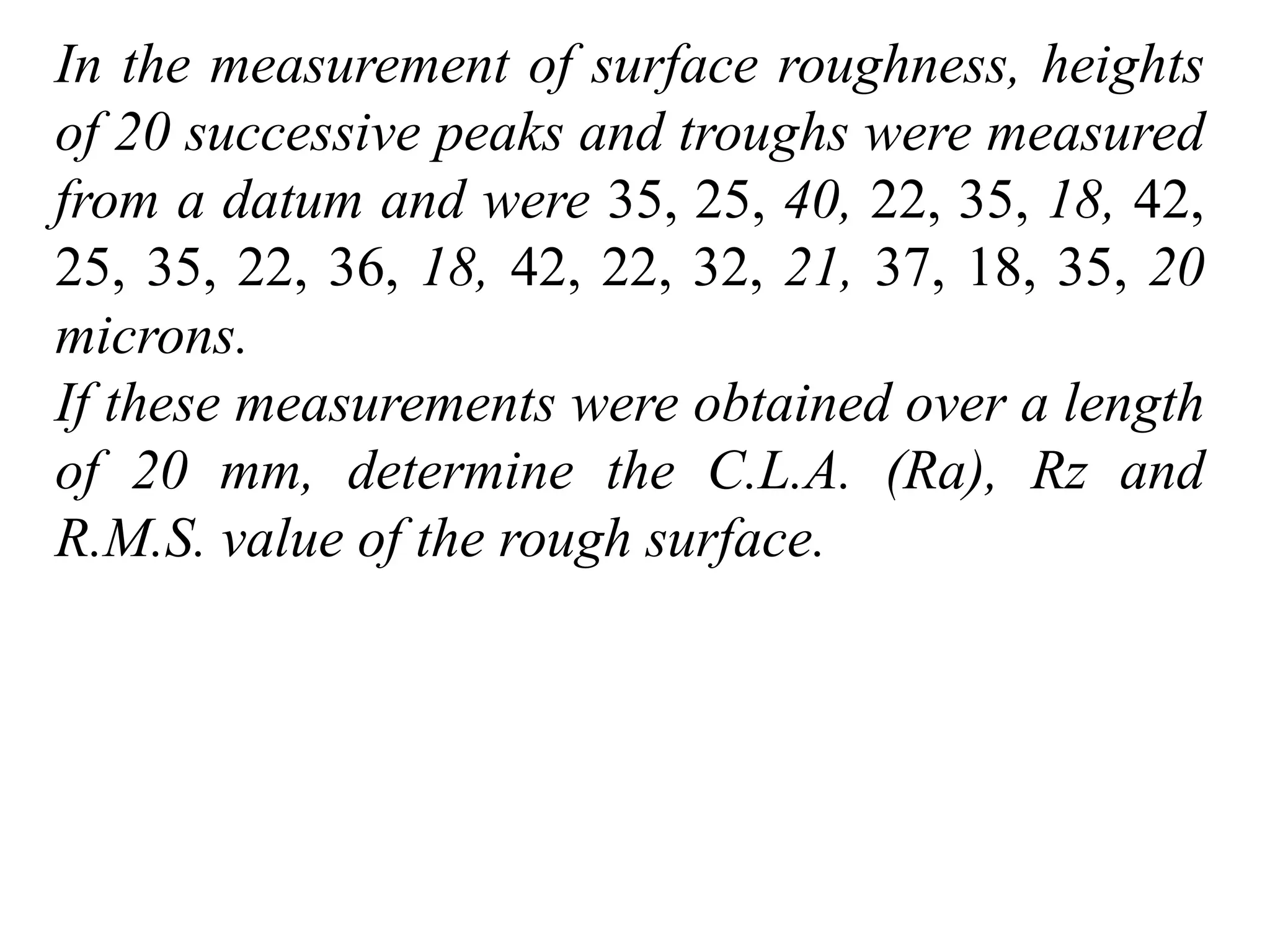

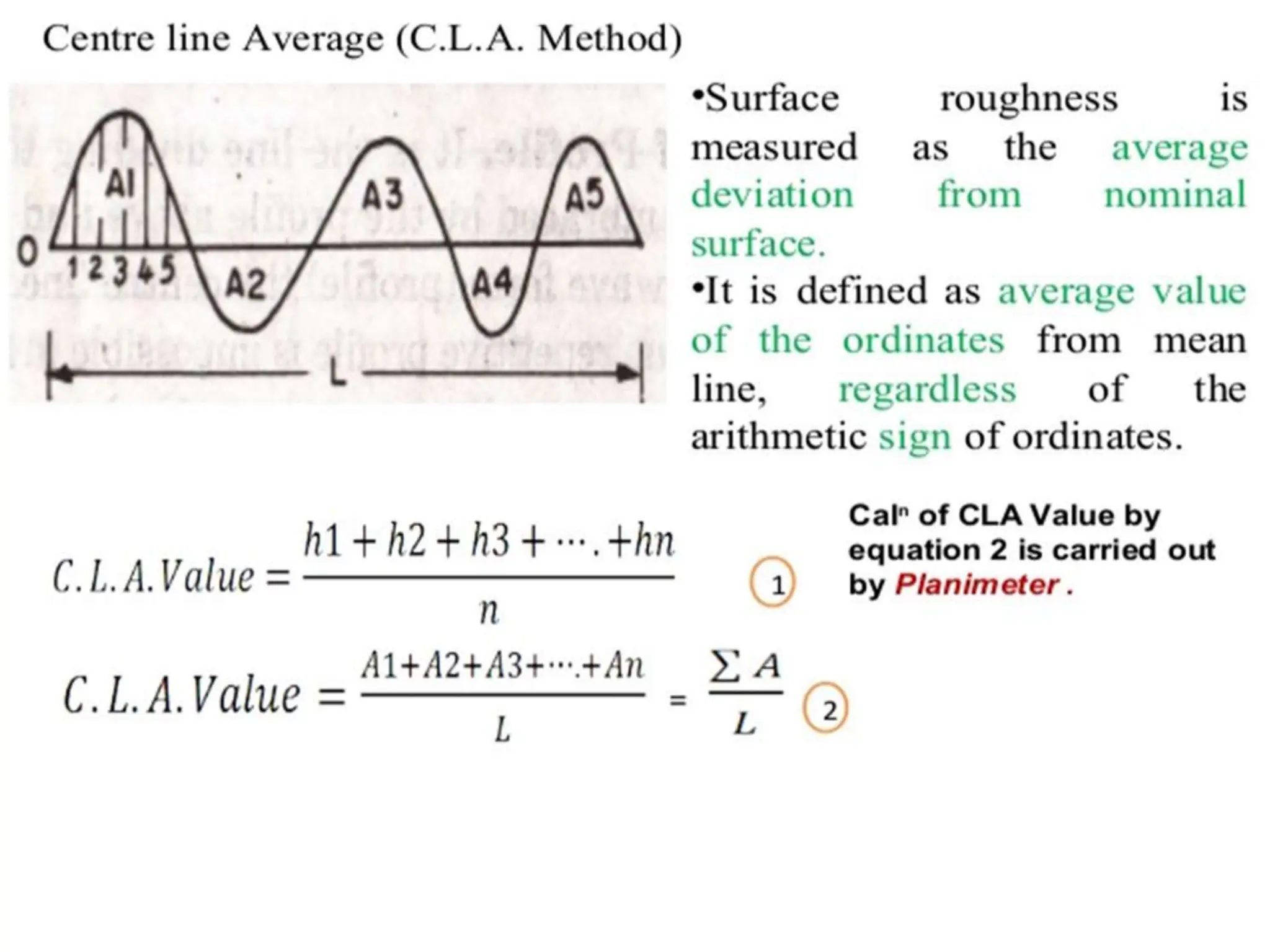

This document discusses surface texture and roughness measurement. It defines key terms like roughness, waviness, forms, flaws and lay. It explains that surface texture has microscopic irregularities from machining and macro irregularities from mechanical disturbances. Roughness refers to microscopic texture from tool marks, while waviness is the underlying macro texture. The document also outlines common surface roughness grades and symbols used on drawings. It provides examples of how to calculate average roughness (Ra), maximum height (Rz) and root mean square values from measurement data.