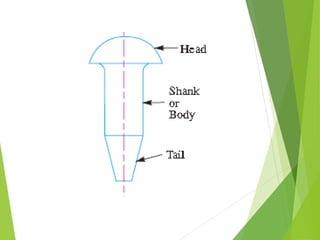

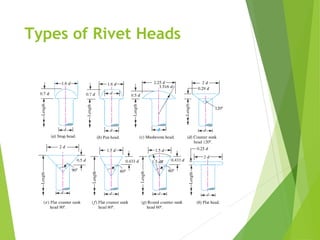

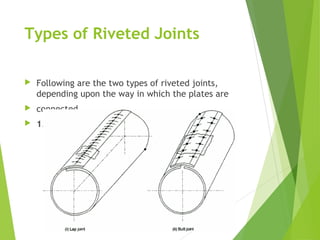

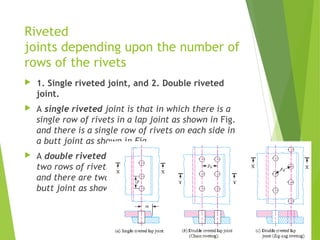

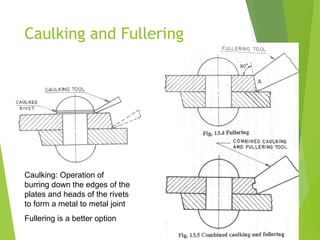

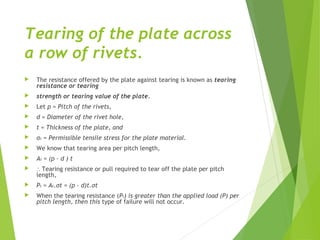

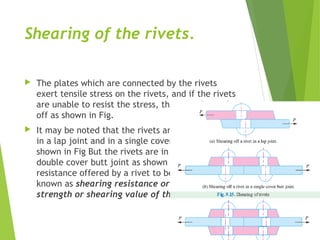

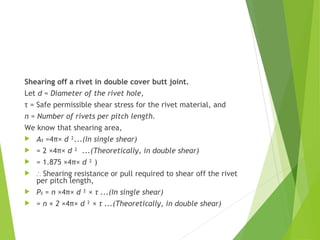

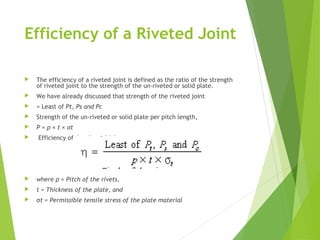

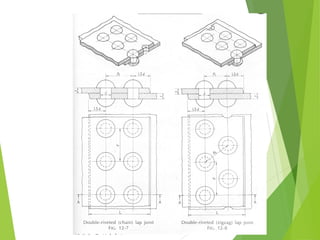

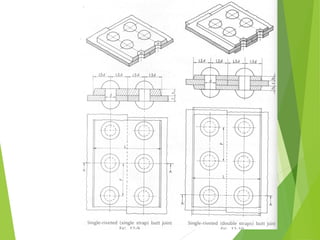

This document discusses riveted joints, outlining their structure, types, and applications in engineering, particularly in construction and manufacturing. It explains the concepts of permanent and temporary fastenings, different types of joints (lap and butt), and the terminology relevant to riveted joints, such as pitch and margin. Additionally, it covers common failure modes, including tearing, shearing, and crushing, as well as the efficiency of riveted joints compared to solid plates.