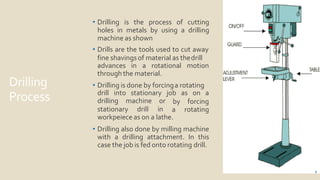

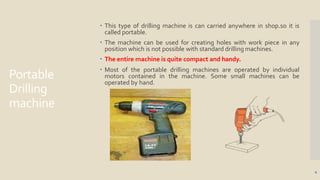

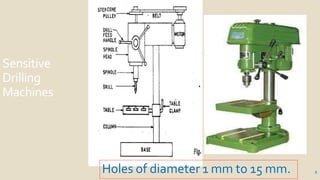

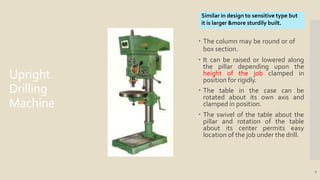

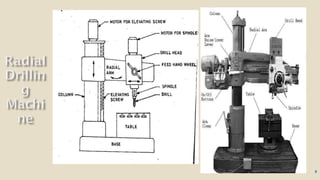

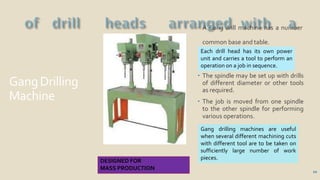

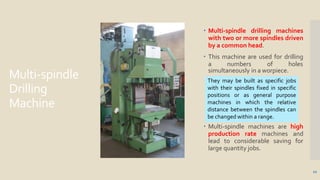

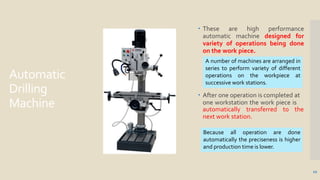

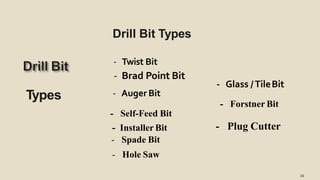

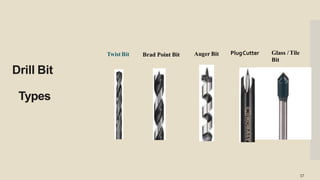

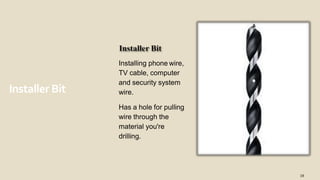

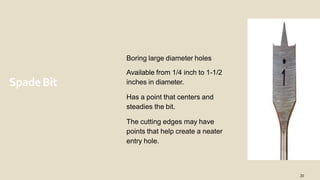

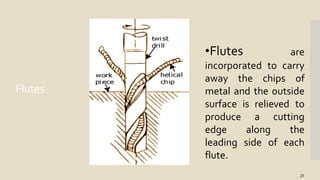

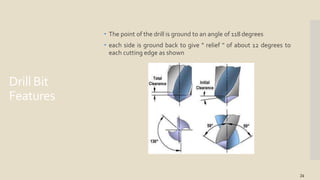

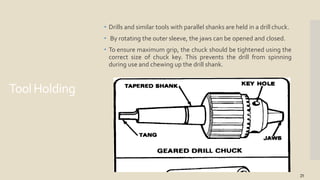

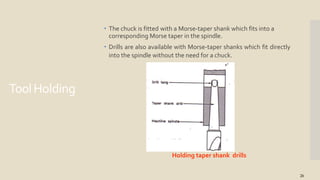

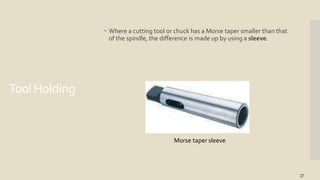

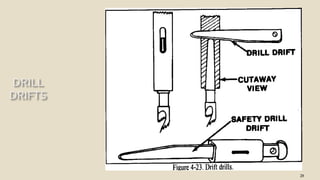

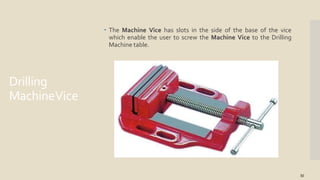

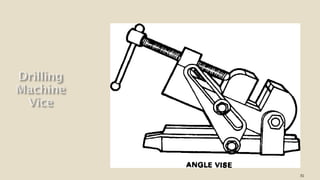

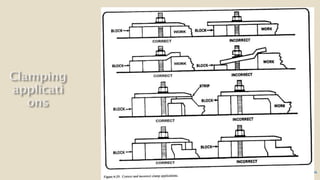

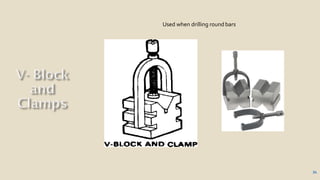

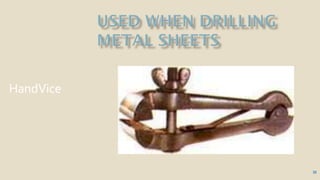

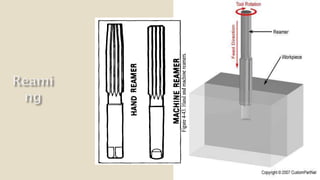

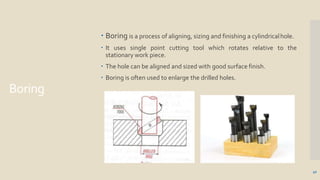

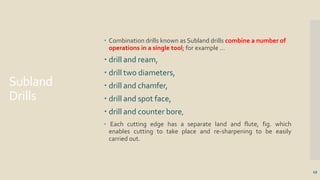

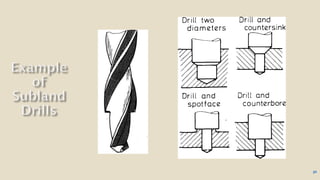

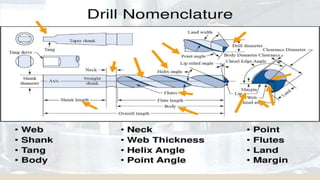

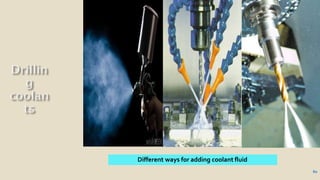

The document outlines the drilling process, describing various types of drilling machines such as portable, sensitive, upright, radial, gang, multi-spindle, and automatic machines, each serving different purposes and configurations. It also discusses drilling operations, drill bits, and toolholding methods, highlighting the importance of securing workpieces and various drilling techniques including drilling, reaming, and tapping. Safety precautions and specifications for drills are also mentioned to ensure accurate and efficient operation.