The document describes the workings of a gas turbine engine. It begins by explaining the basic components and processes of a gas turbine, including the compressor, combustion chamber, and turbine. It then discusses different classifications of gas turbines based on combustion type. Next, it lists some merits of gas turbines over internal combustion engines, as well as some demerits. The document proceeds to outline common assumptions made in analyzing ideal gas turbine cycles. It provides an in-depth explanation of the Brayton cycle as the basic cycle for gas turbines. Finally, it discusses various methods for improving gas turbine efficiency, such as increasing combustion temperatures, improving machine efficiencies, and modifying the basic cycle through regeneration and reheat.

![The expression for thermal efficiency in terms of the

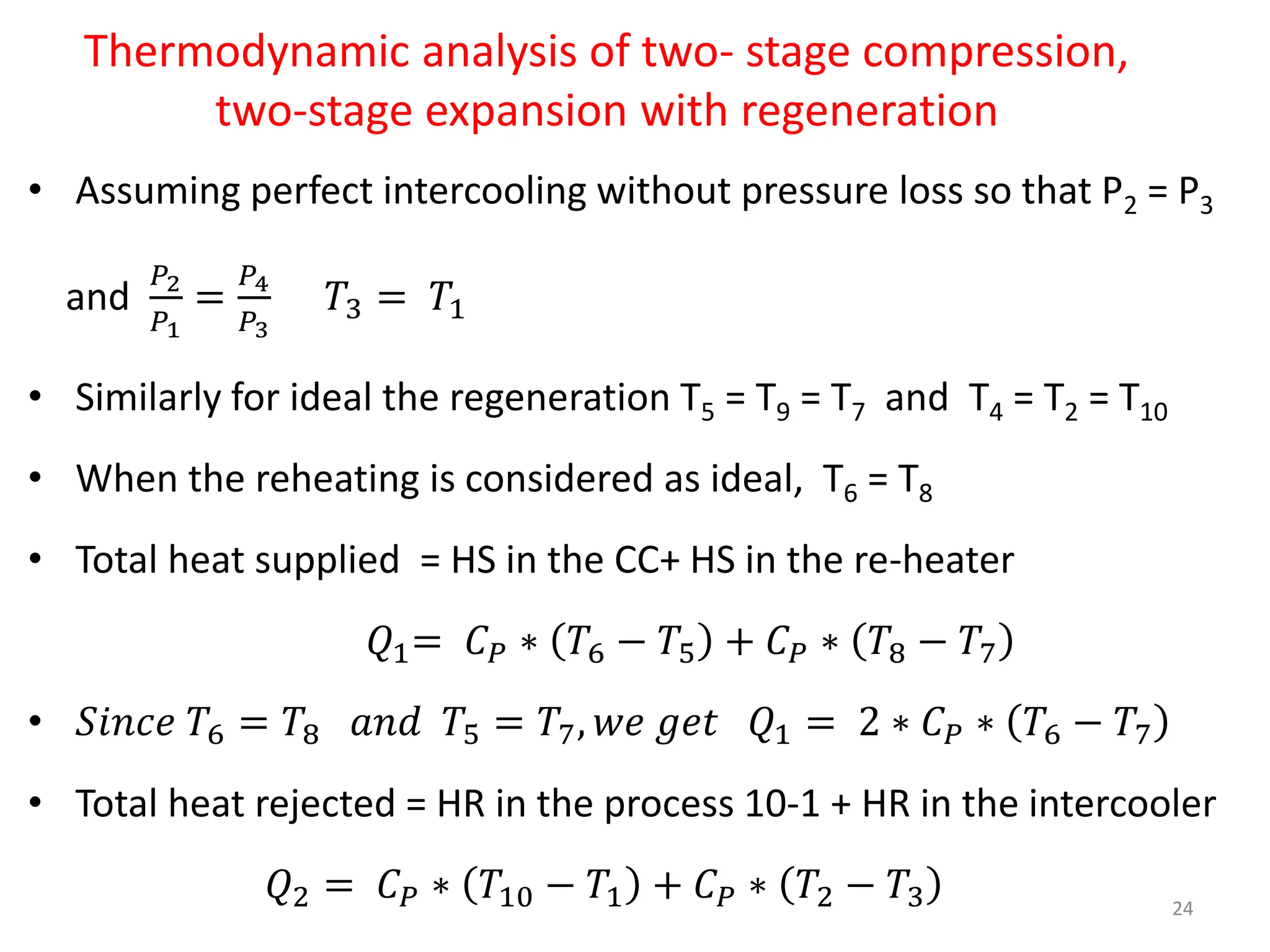

pressure ratio rp

Heat supplied Q1 = m (h3 – h2) = m Cp[T3 – T2]

Heat rejected Q2 = m (h4 – h1) = m Cp[T4 – T1]

For the reversible adiabatic process 1-2 we have,

𝑇2

𝑇1

=

𝑃2

𝑃1

𝛾−1

𝛾

= 𝑟𝑝

𝛾−1

𝛾

𝑇ℎ𝑒𝑟𝑚𝑎𝑙 𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 𝑜𝑟 𝐶𝑦𝑐𝑙𝑒 𝑒𝑓𝑓𝑖𝑐𝑒𝑖𝑛𝑐𝑦

𝜂𝑡ℎ𝑒𝑟𝑚𝑎𝑙 = 1 −

𝑄2

𝑄1

= 1 −

𝑚 𝐶𝑝 𝑇4 − 𝑇1

𝑚 𝐶𝑝 𝑇3 − 𝑇2

= 1 −

(𝑇4 − 𝑇1

(𝑇3 − 𝑇2

9](https://image.slidesharecdn.com/gasturbinecycles-240314070243-c6955295/75/gas-turbine-cycles-pptx-9-2048.jpg)