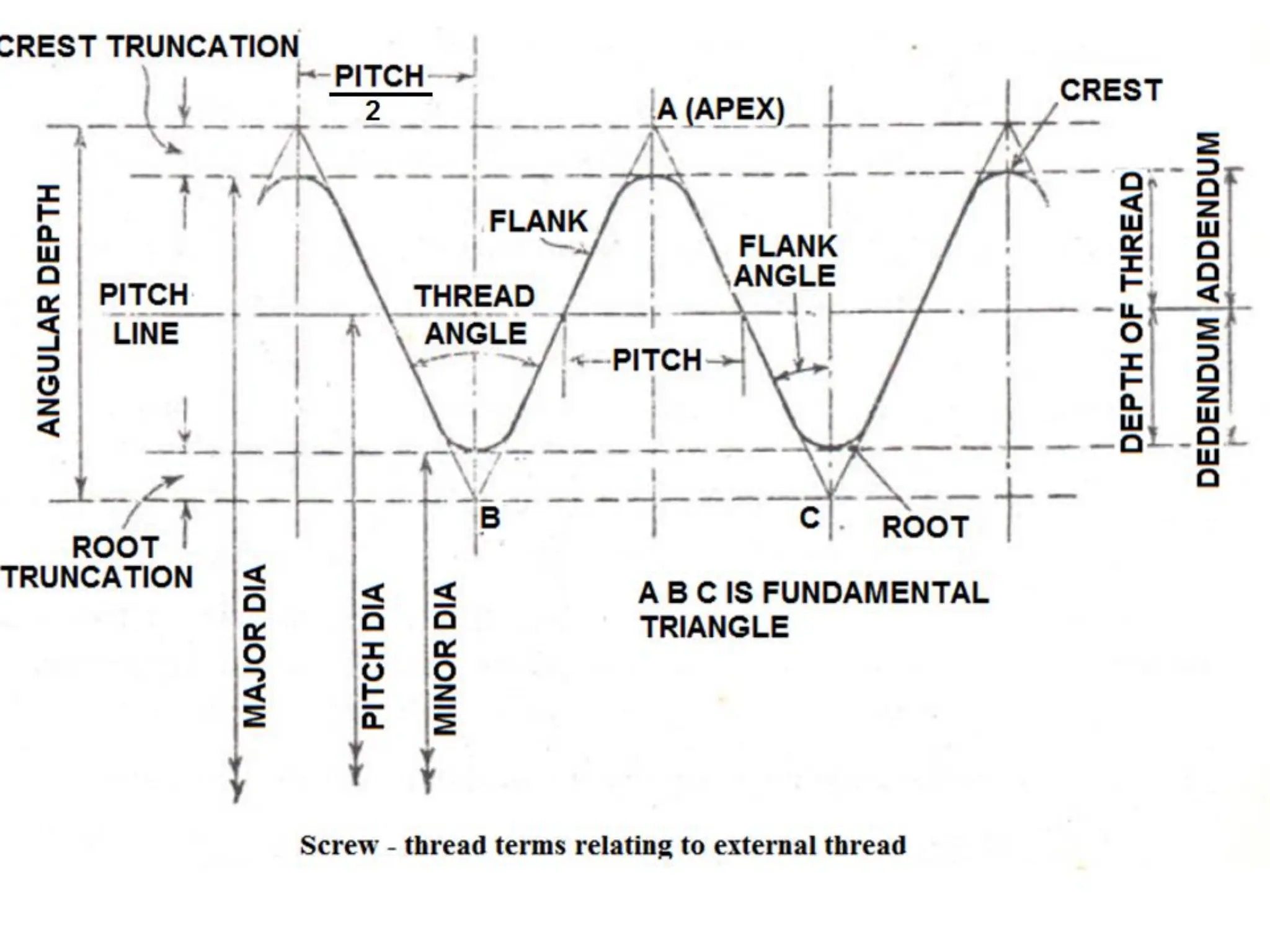

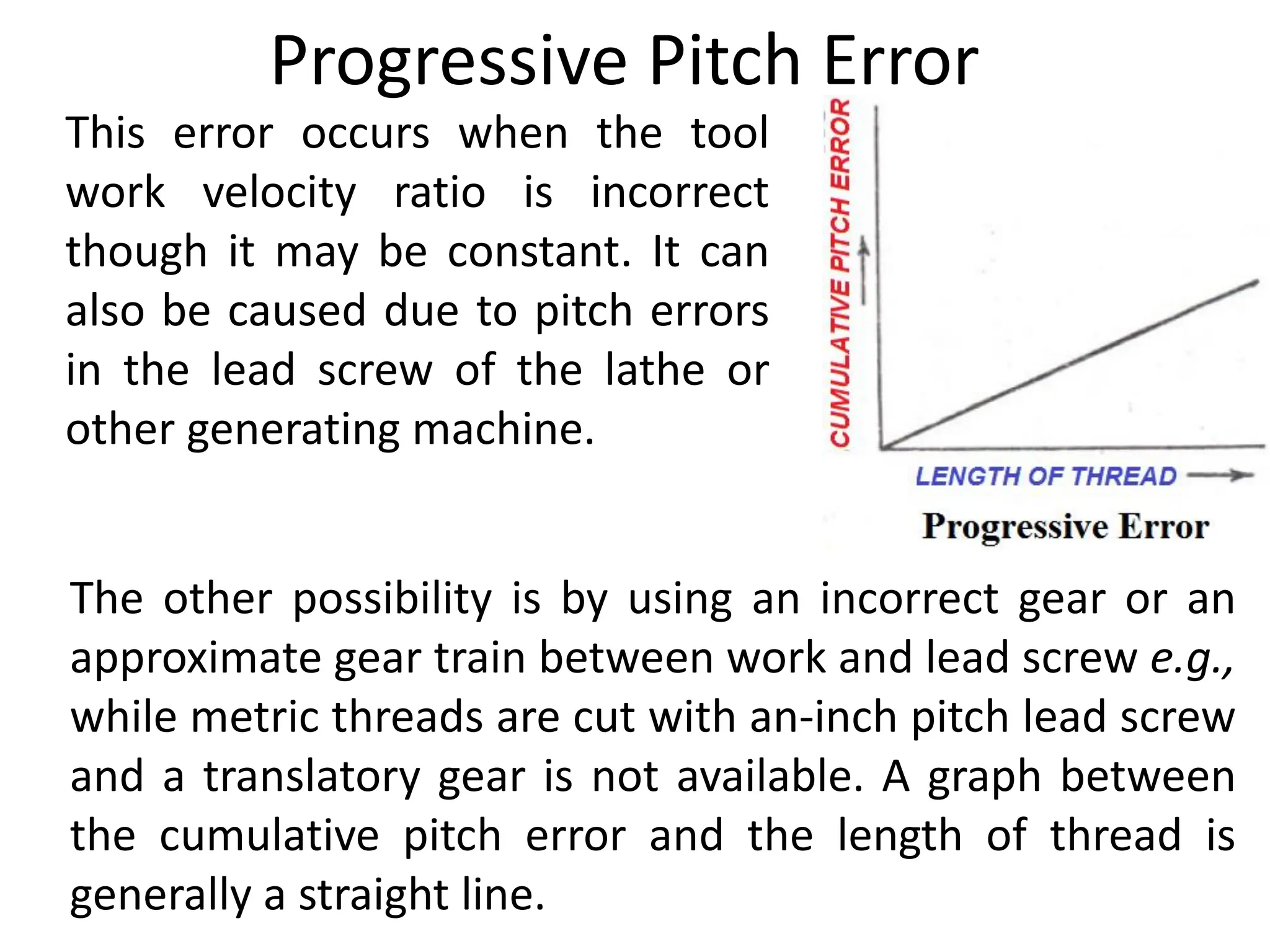

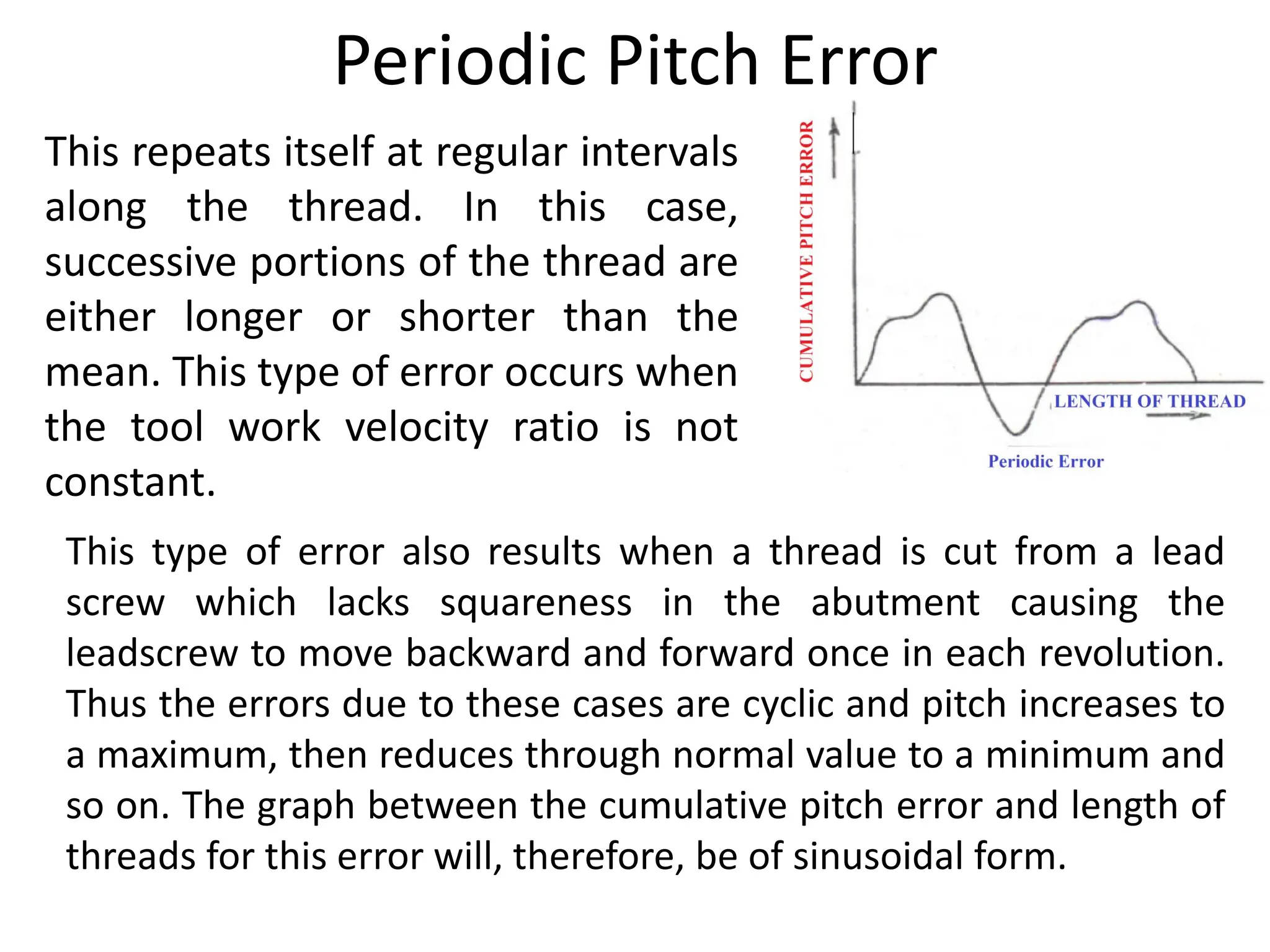

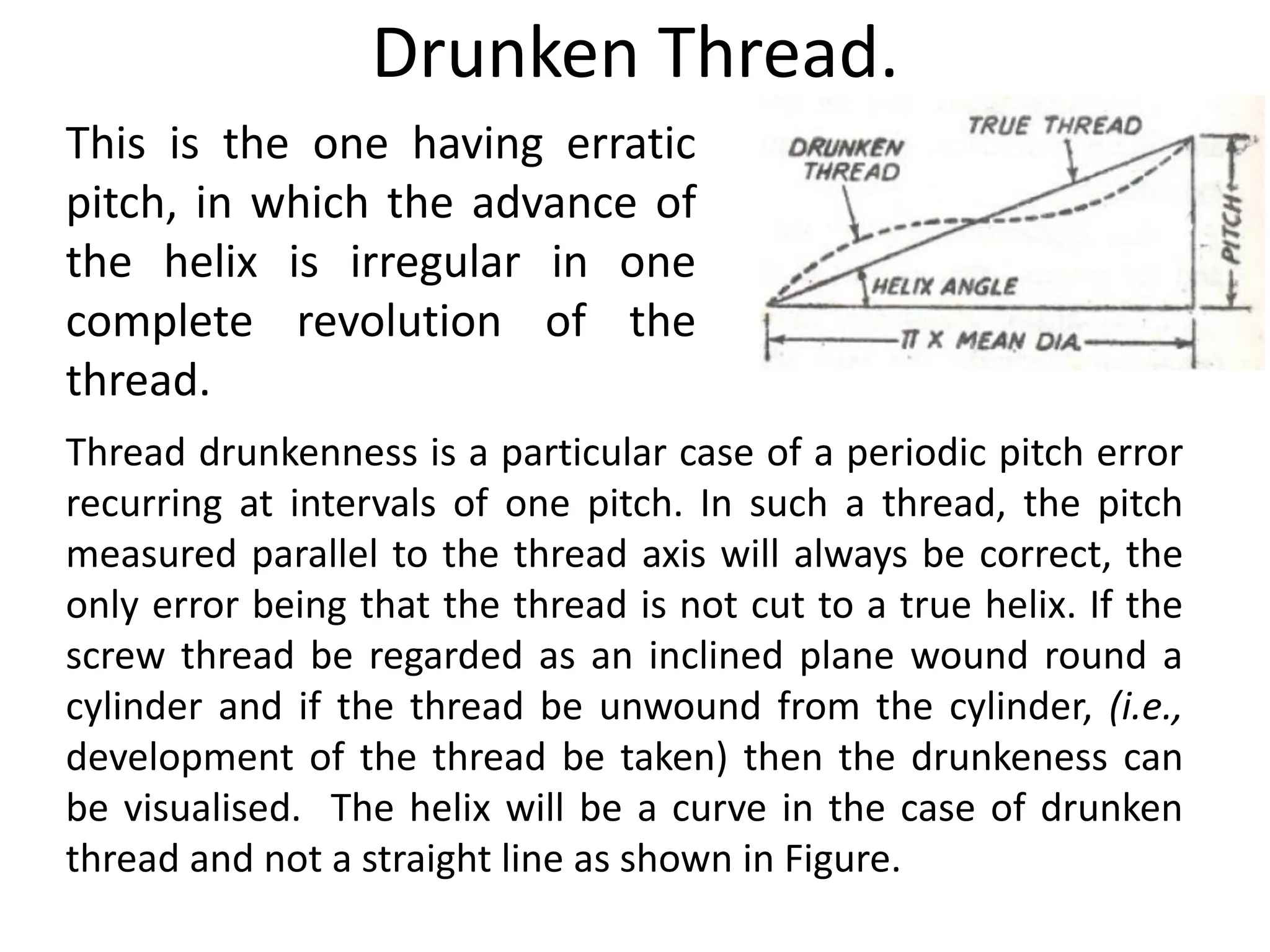

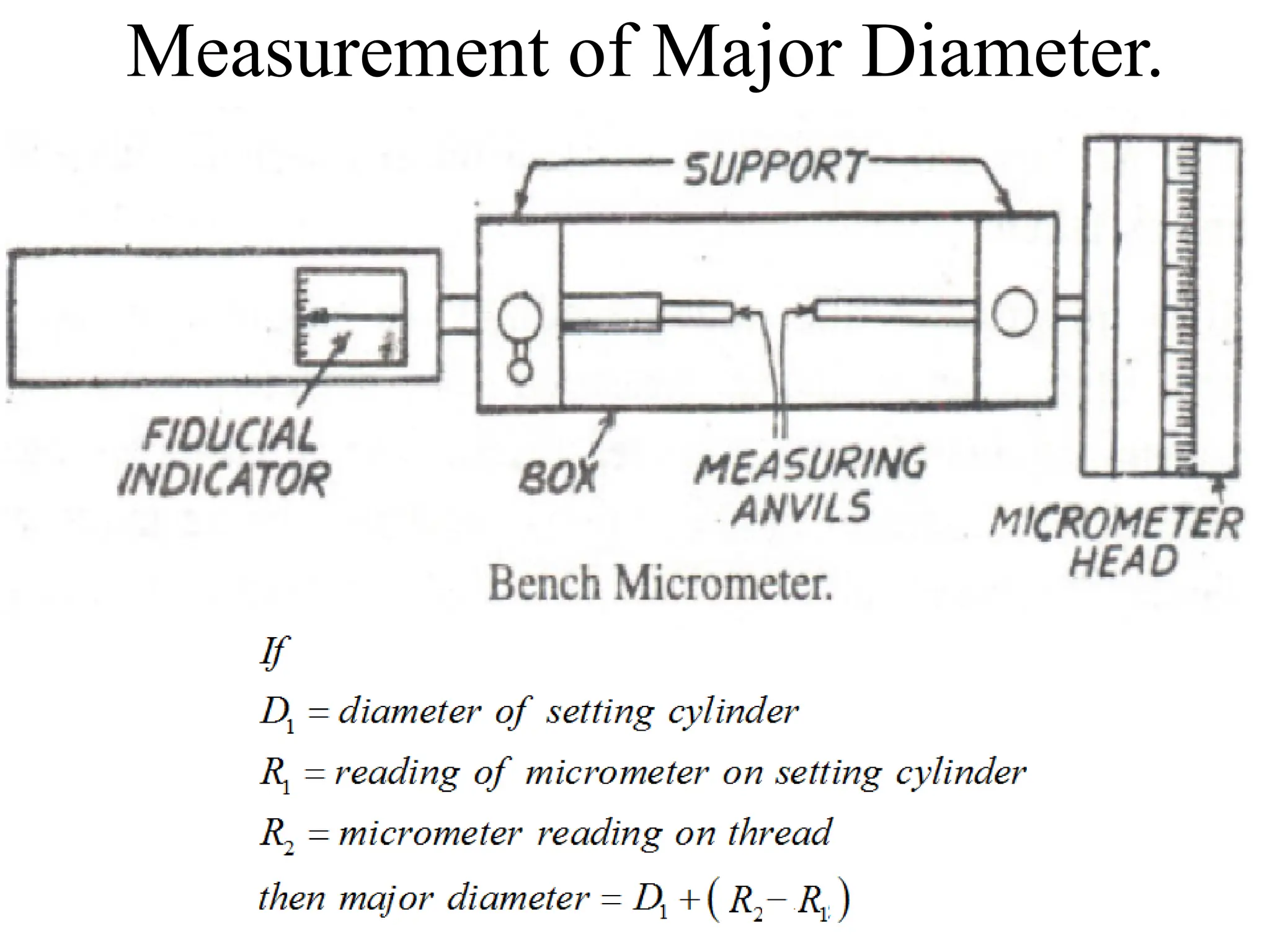

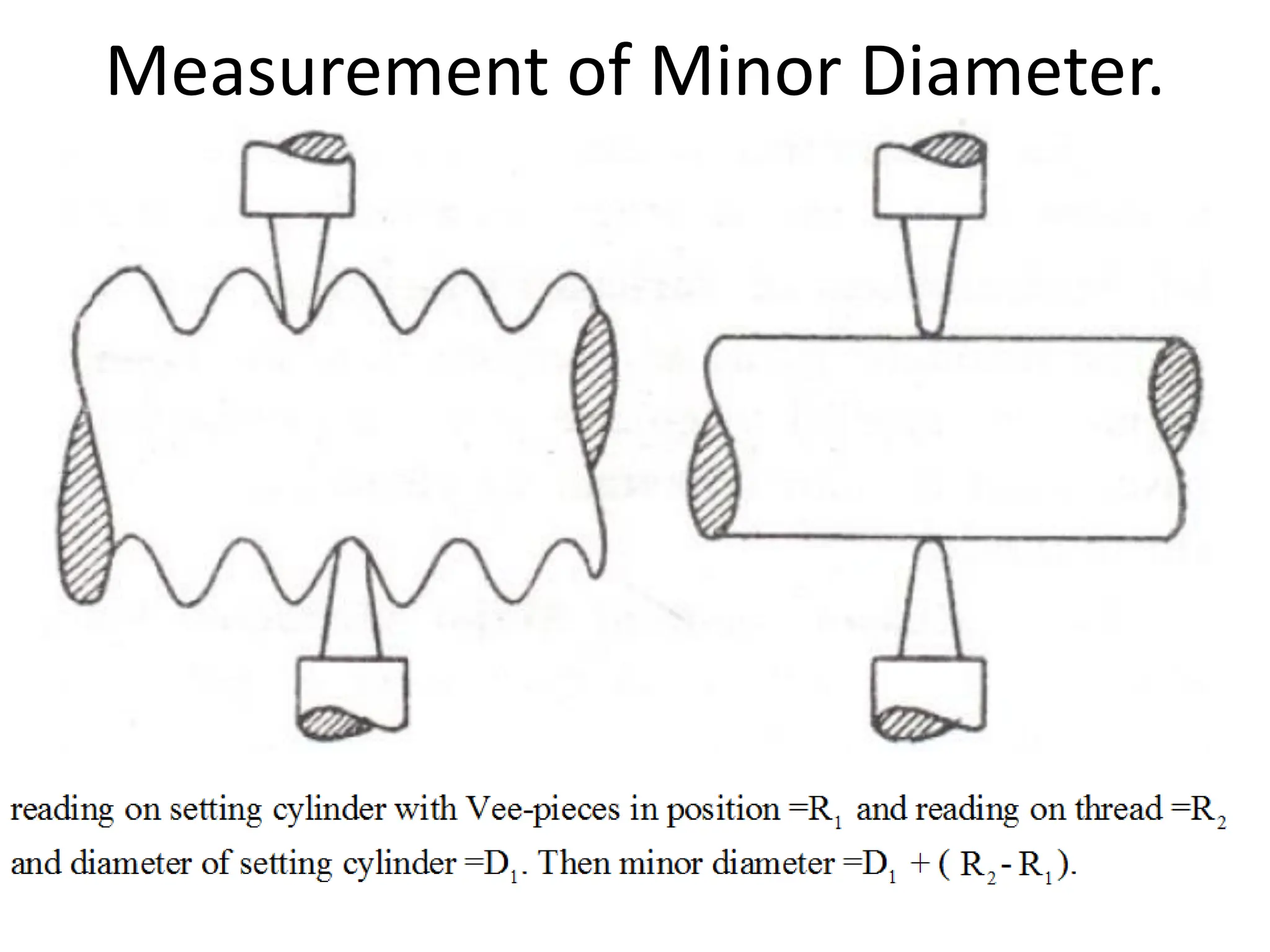

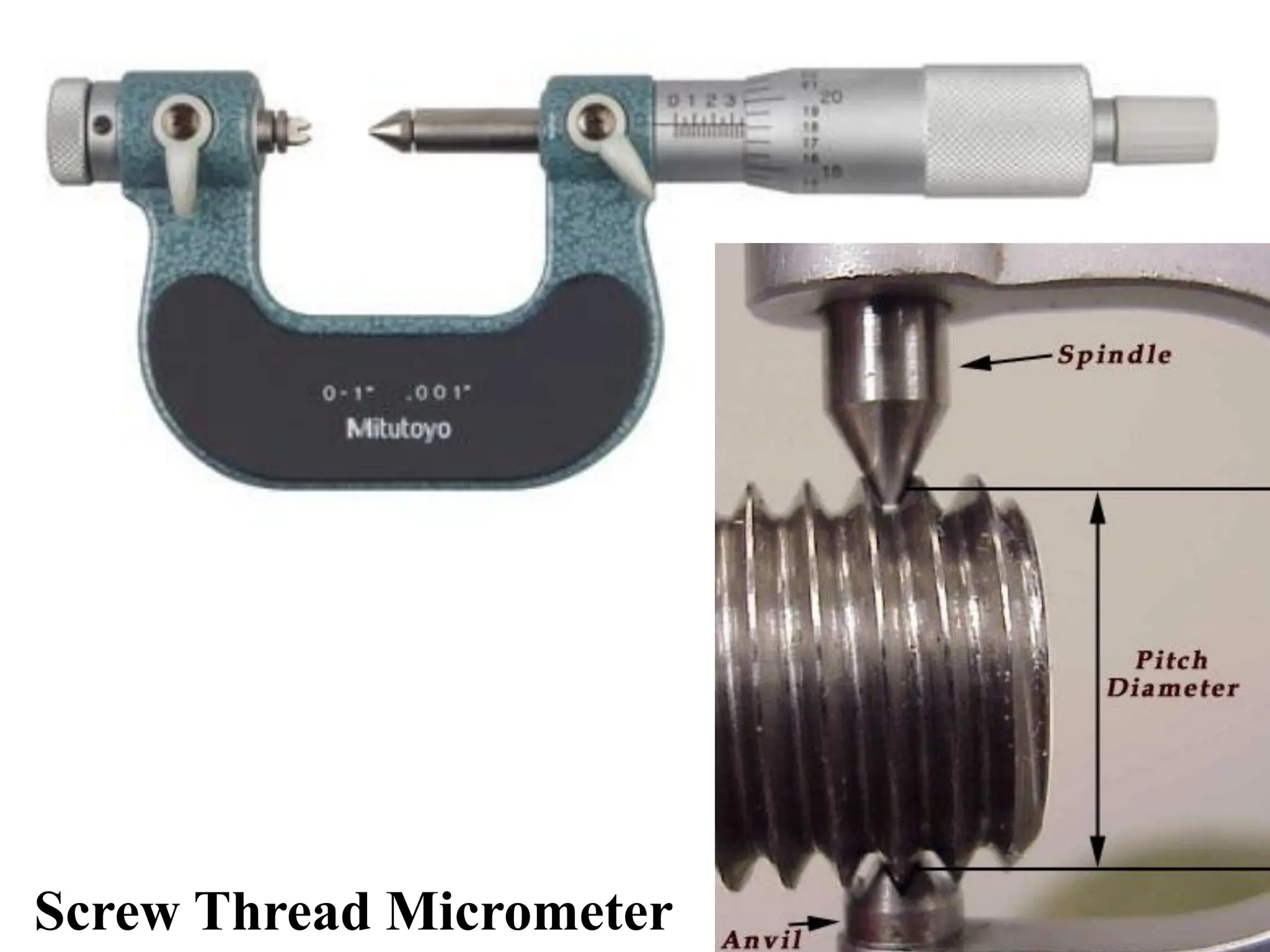

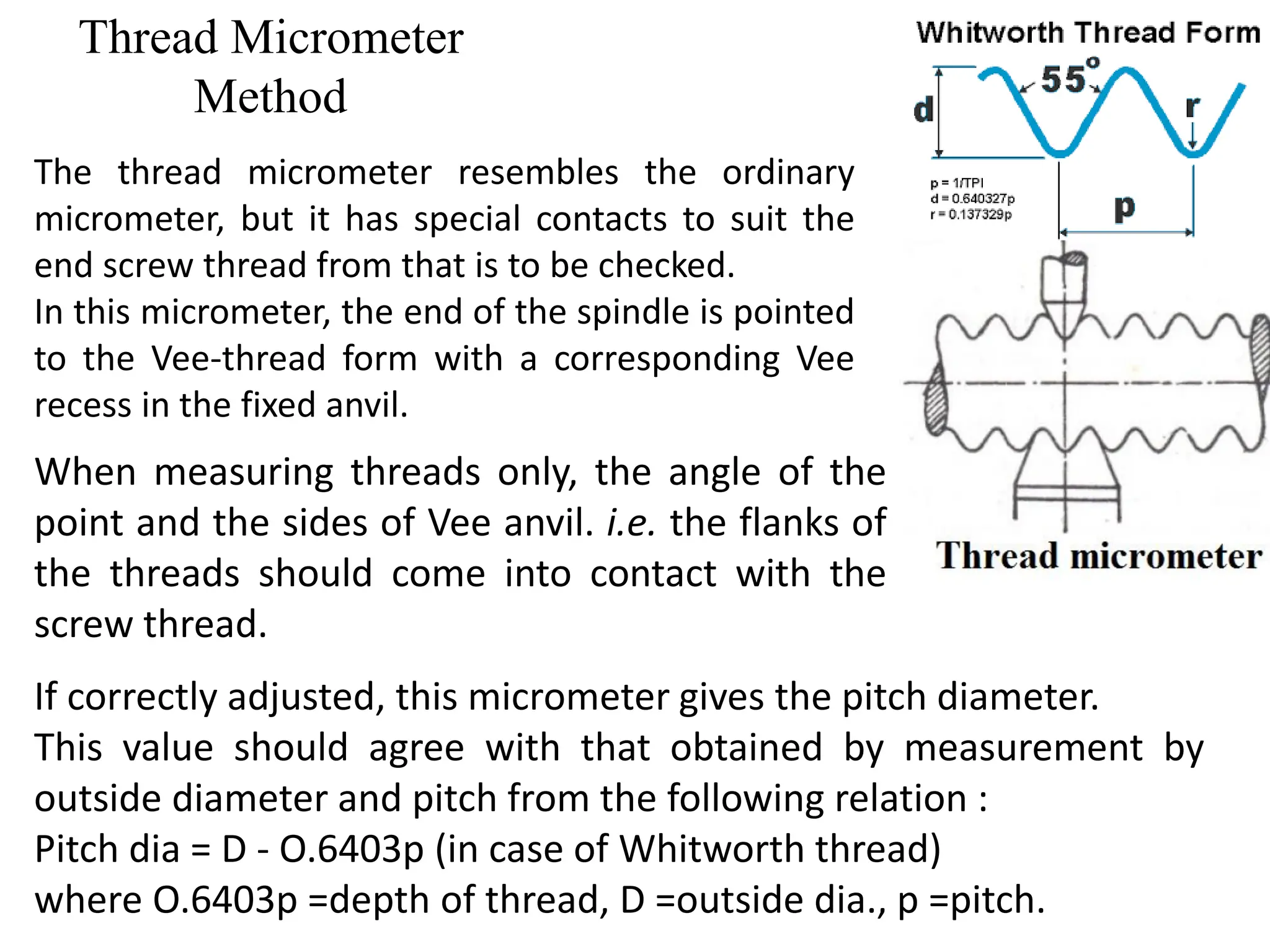

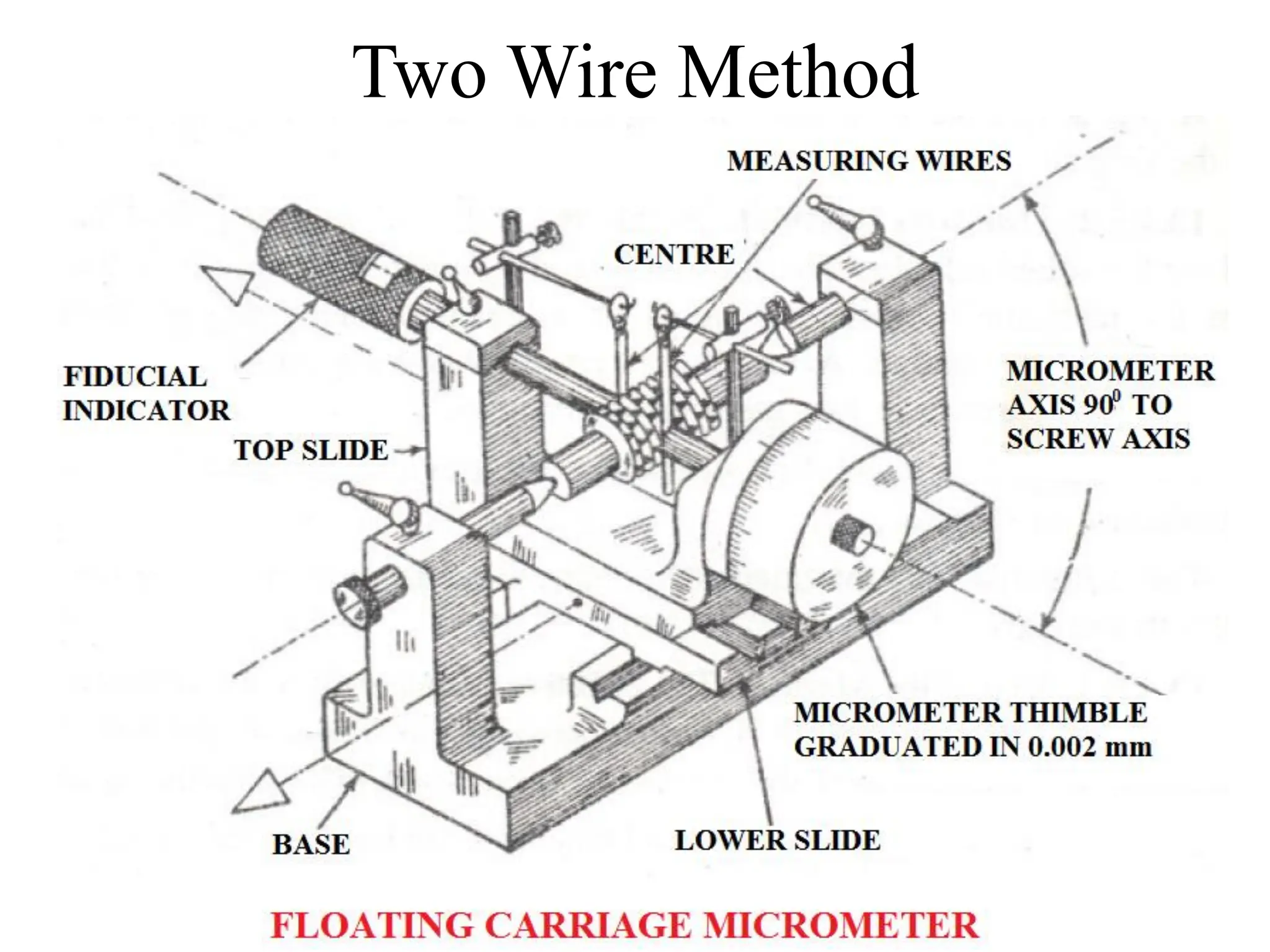

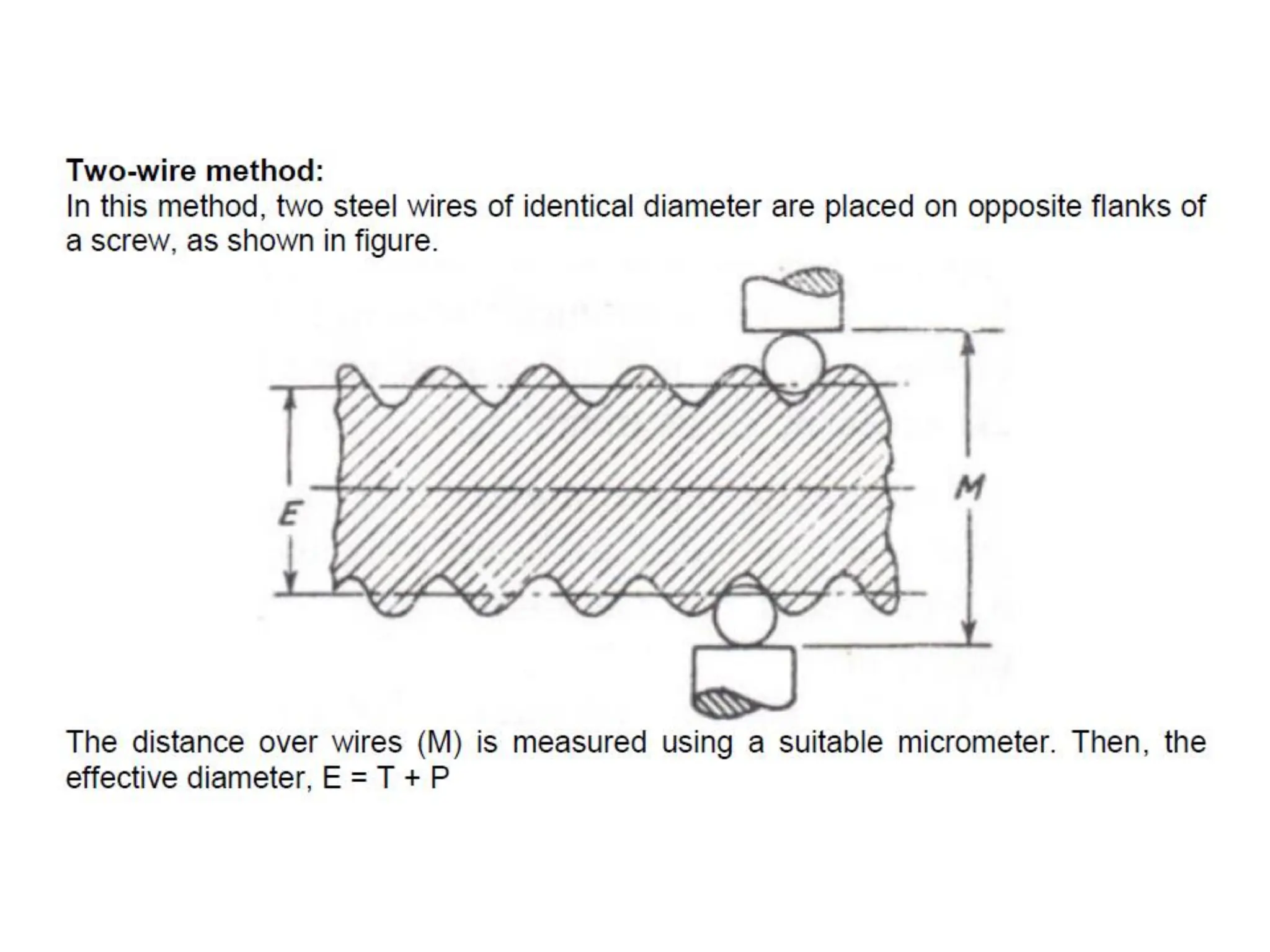

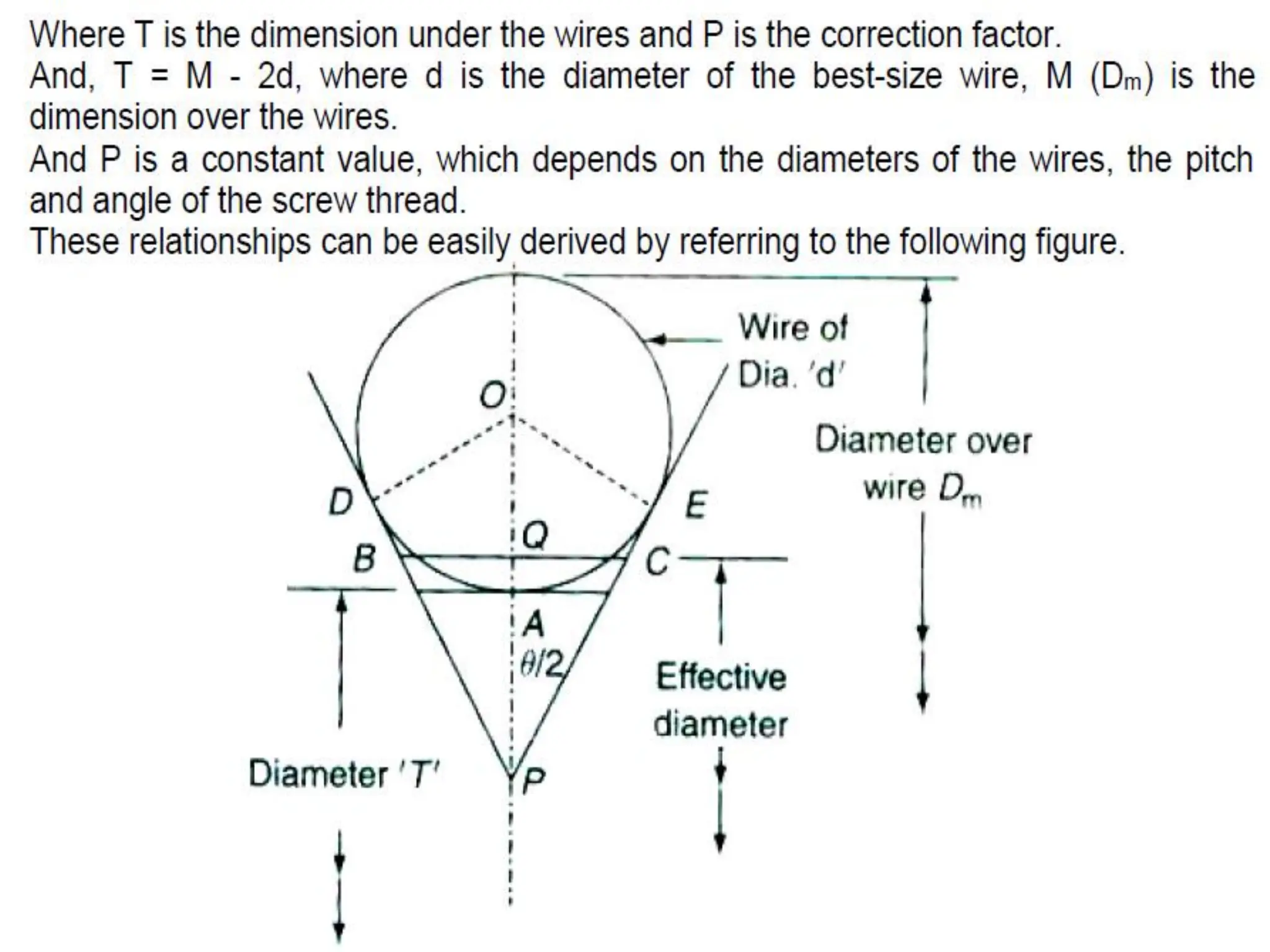

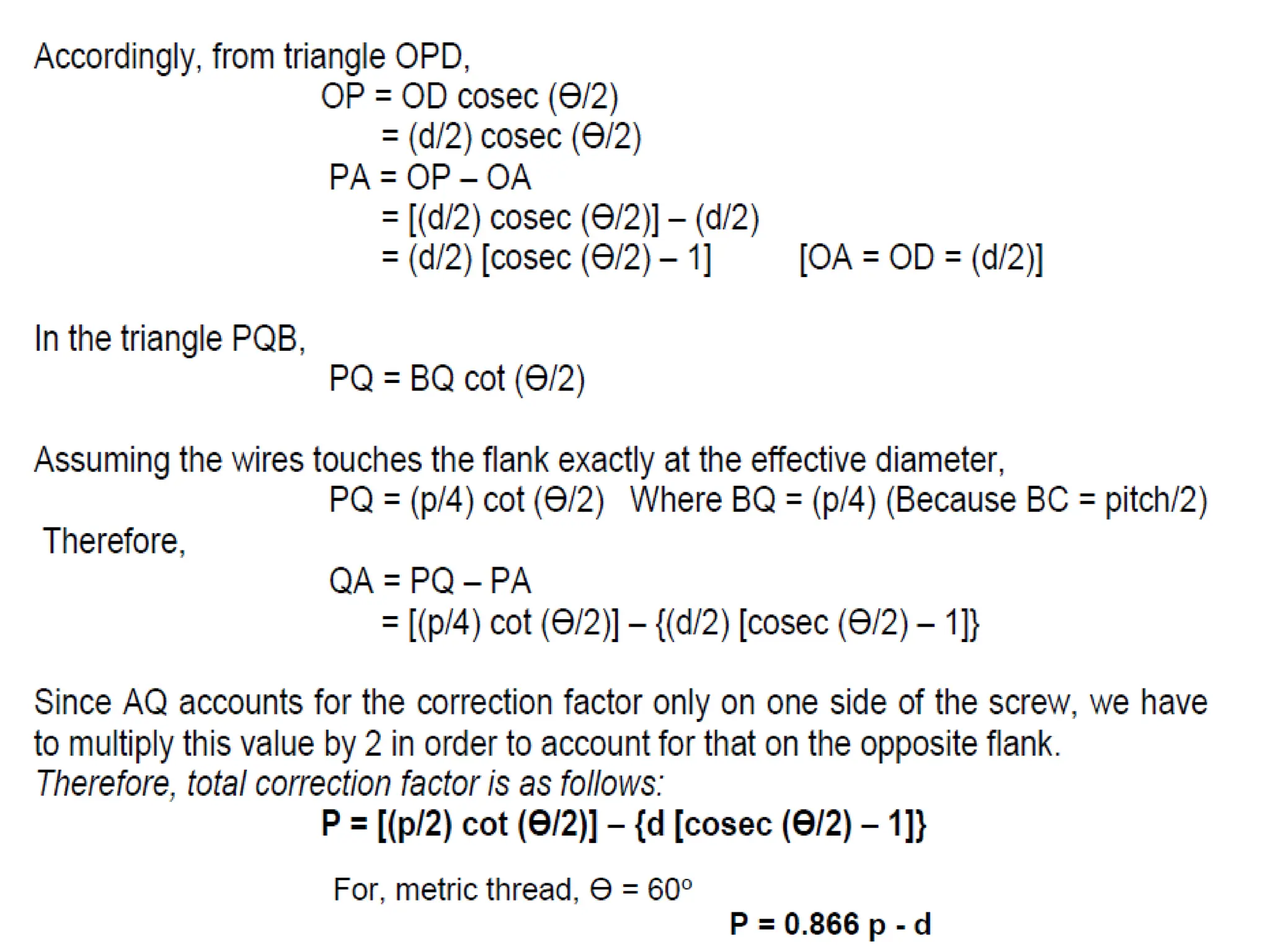

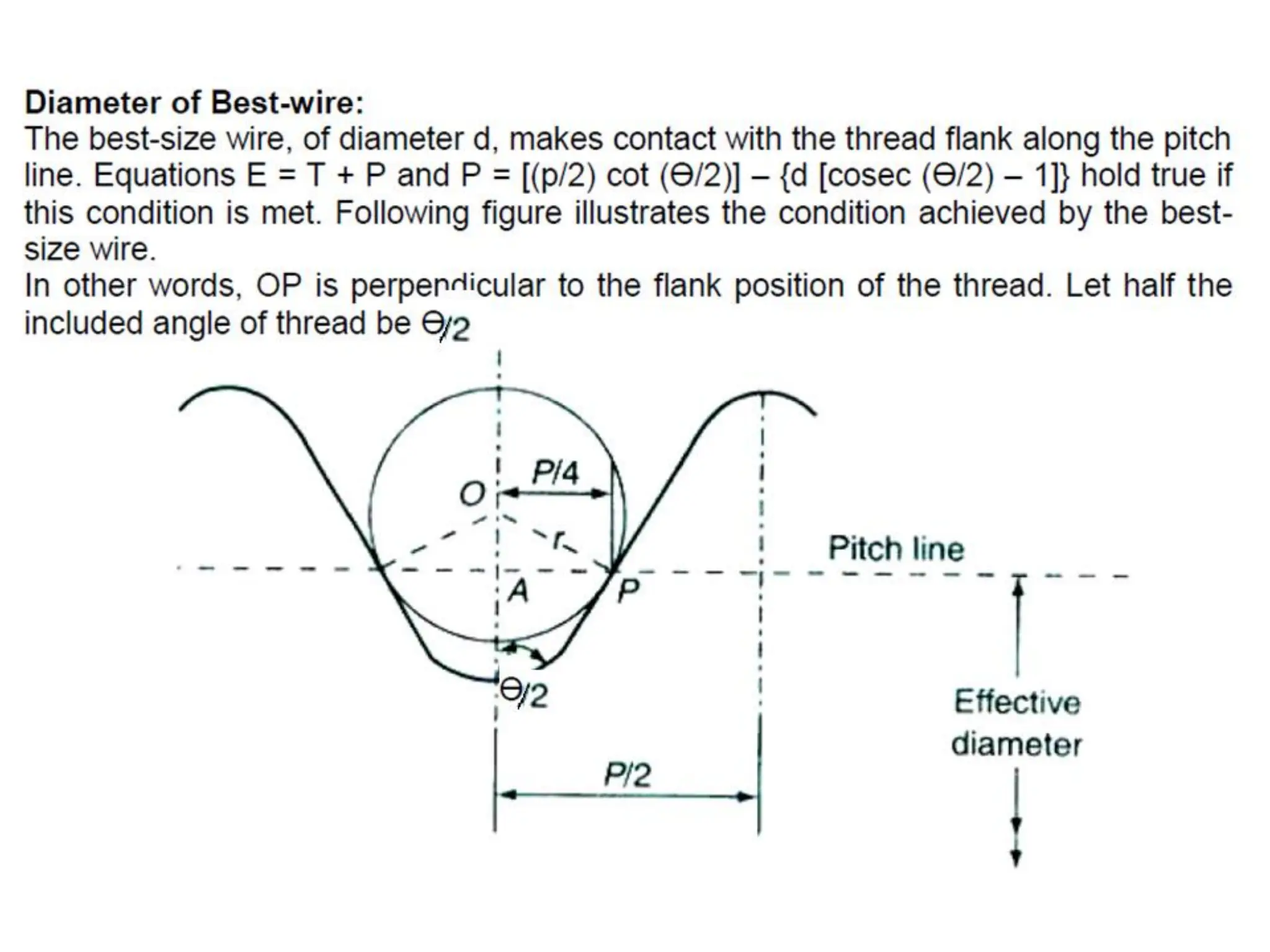

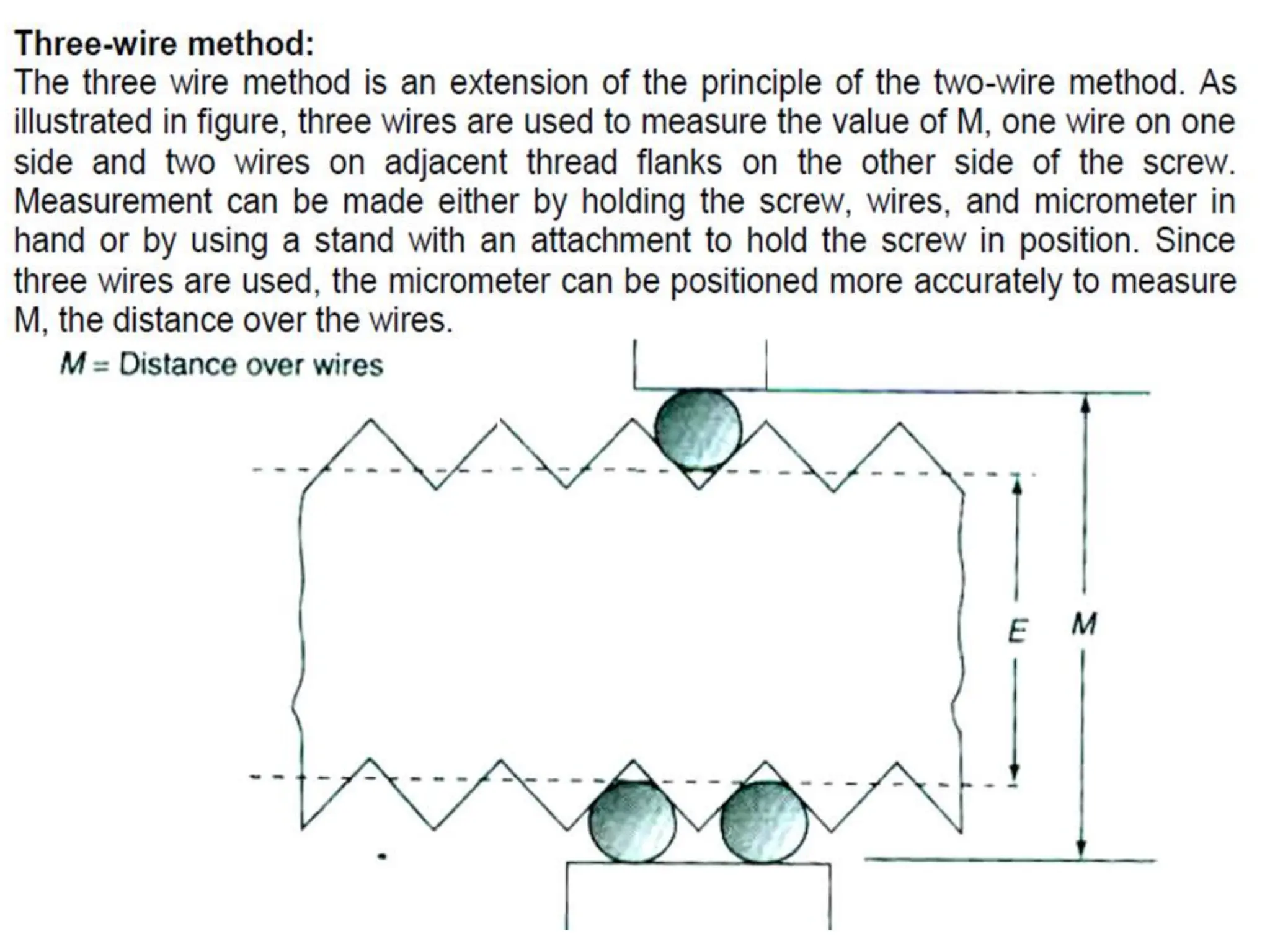

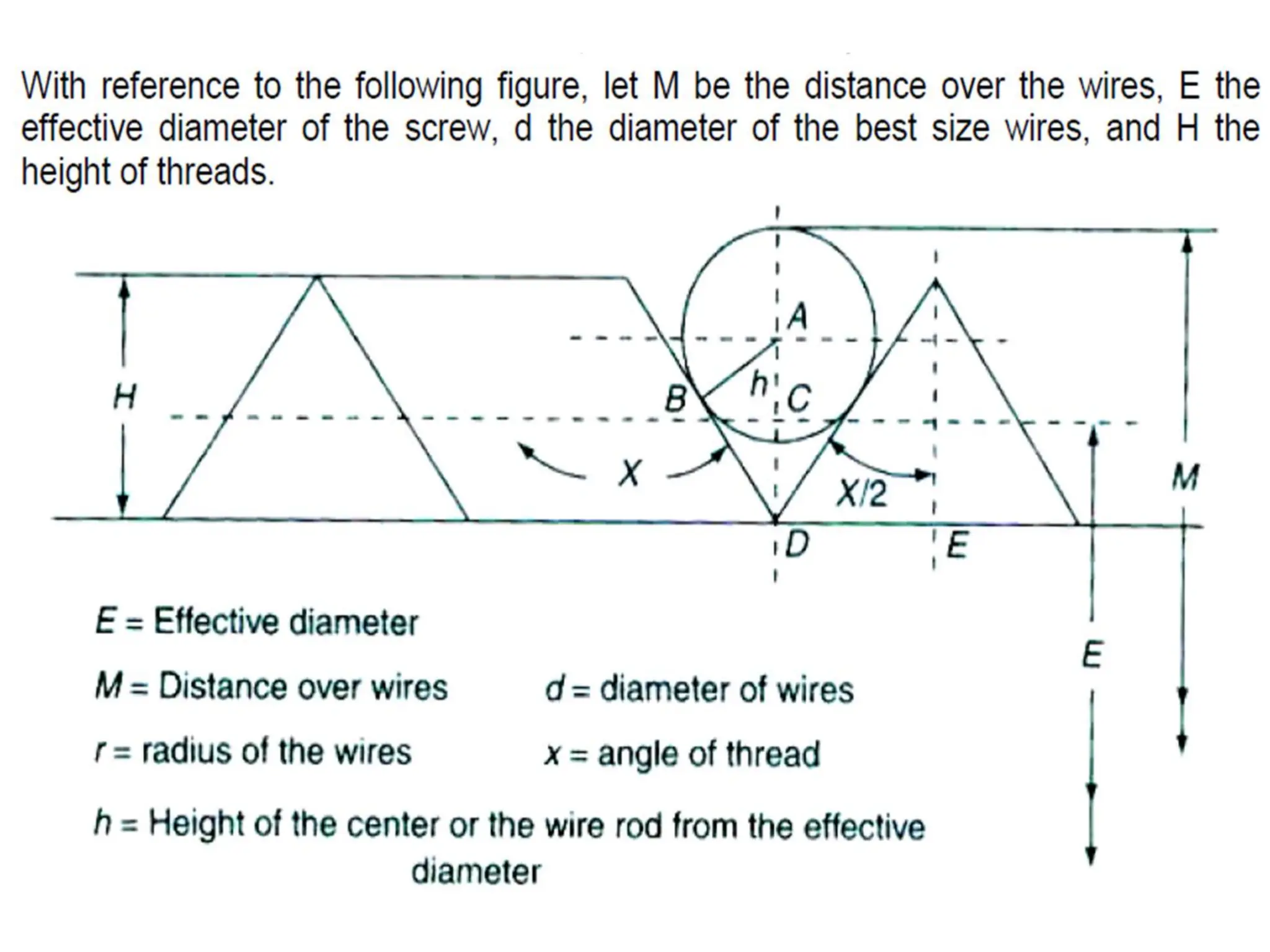

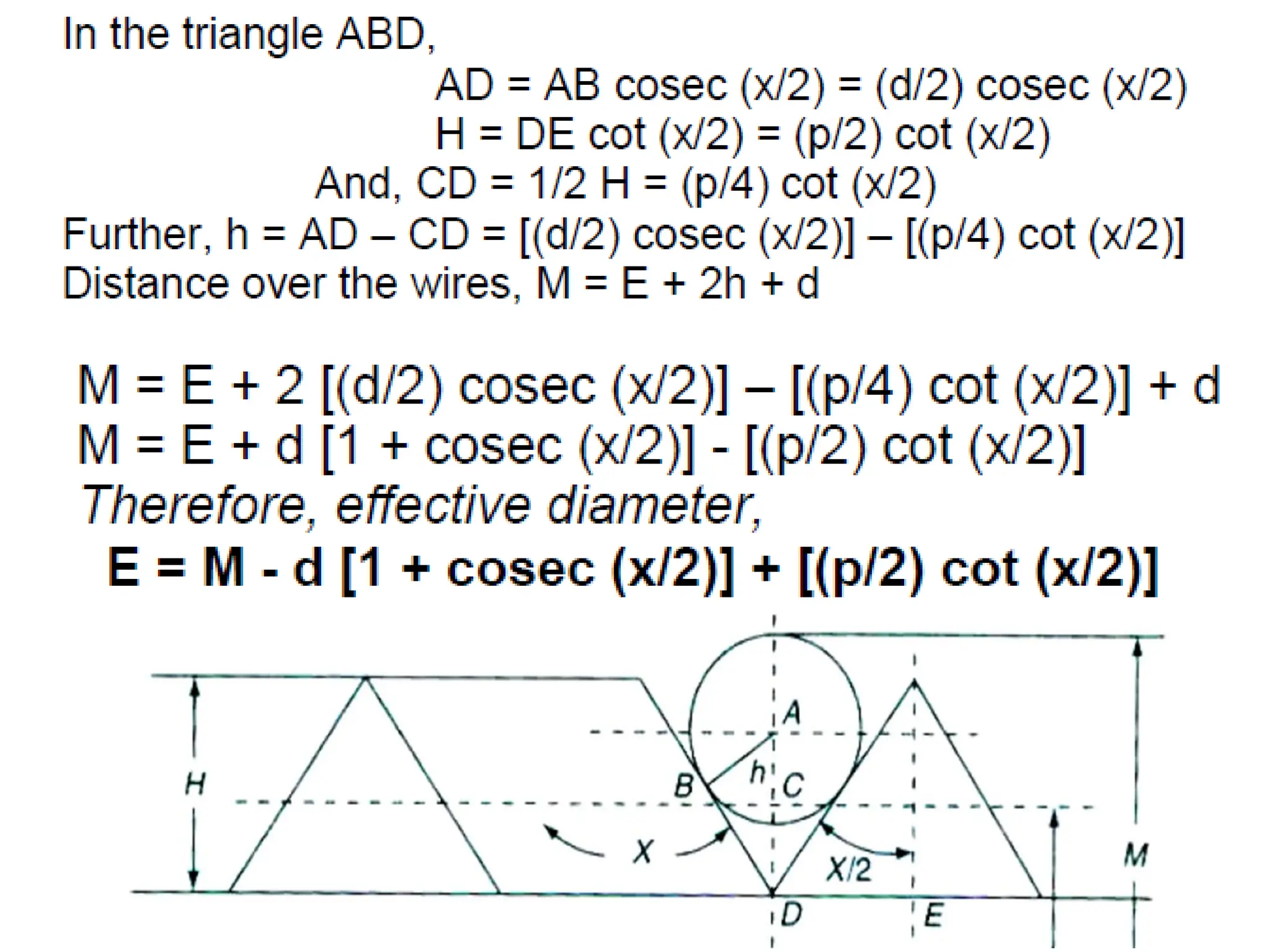

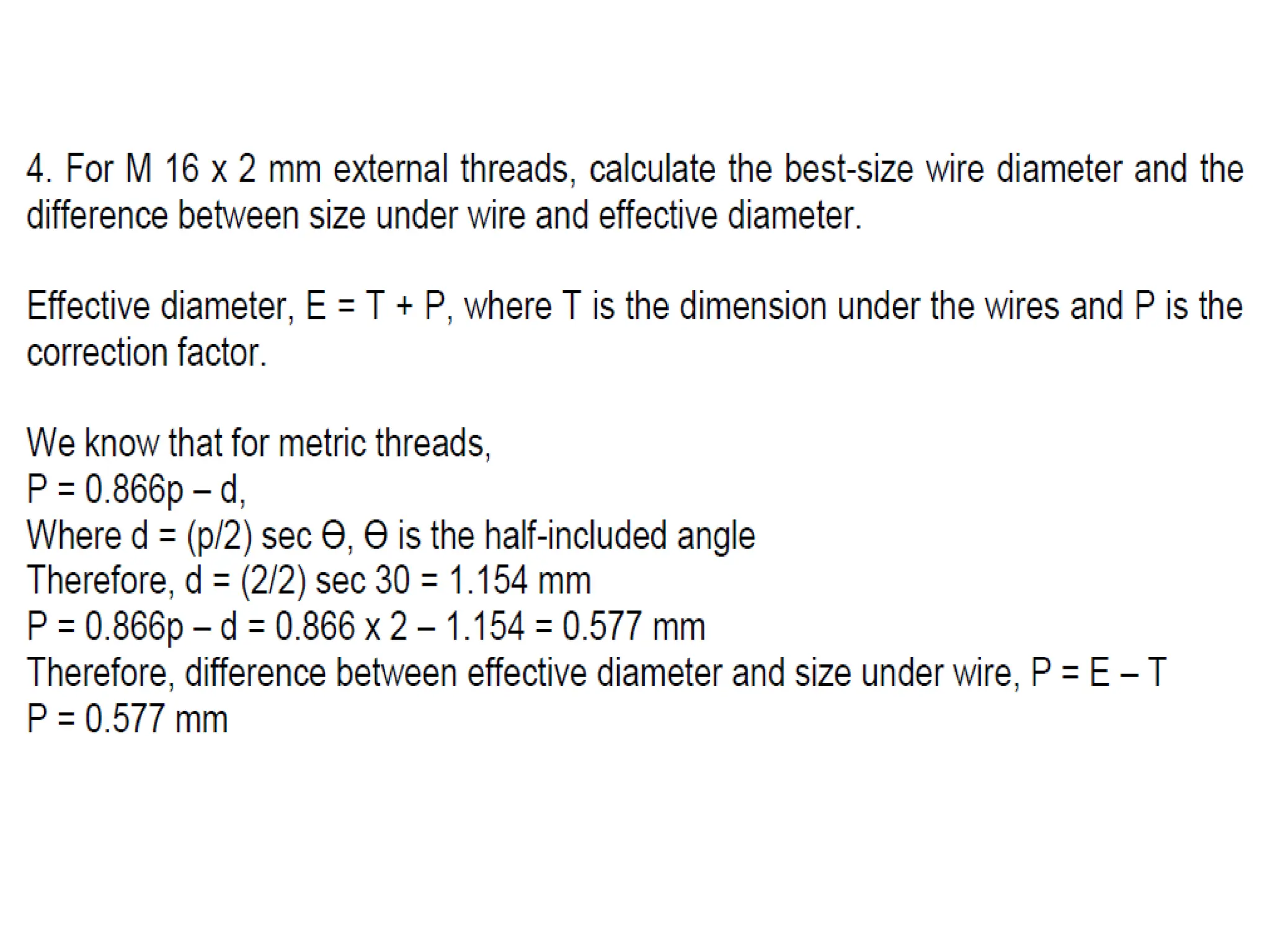

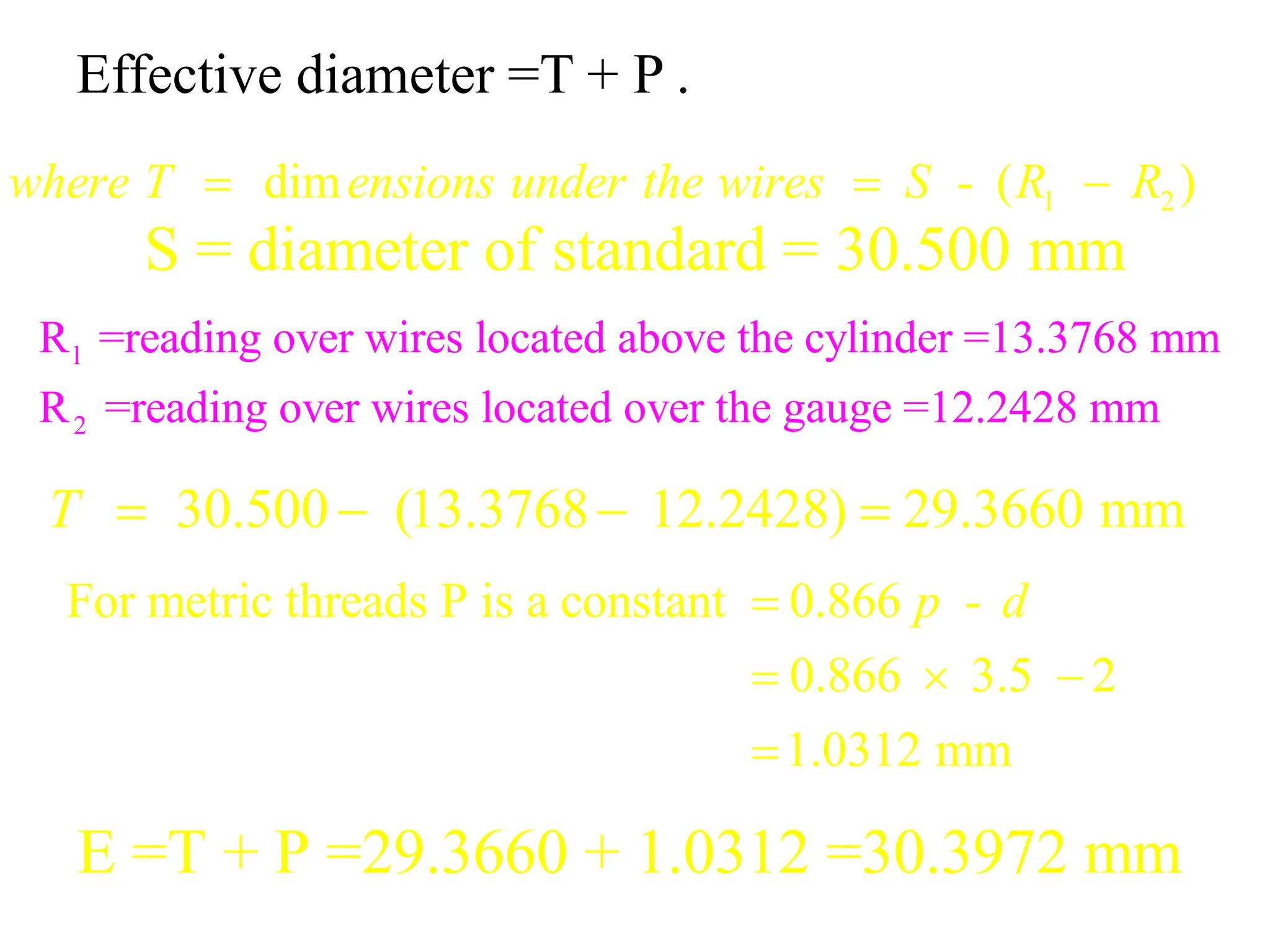

This document discusses the measurement of screw threads. It defines various screw thread terminology such as crest, root, flank, pitch, and angle of thread. It describes common types of pitch errors in screw threads such as progressive, periodic, and drunken threads. It also outlines various methods for measuring important screw thread dimensions like major diameter, minor diameter, and effective diameter. These include using a bench micrometer, thread micrometer, and two-wire method. Accurately measuring thread features is important for evaluating thread quality and fit.