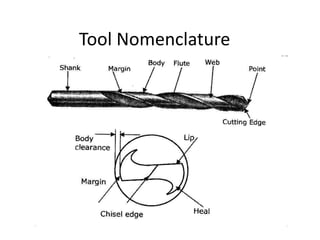

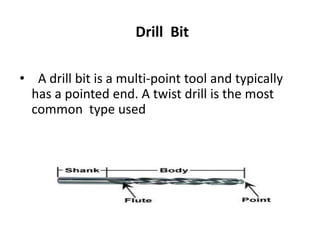

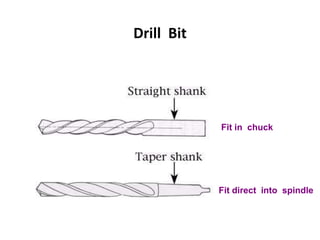

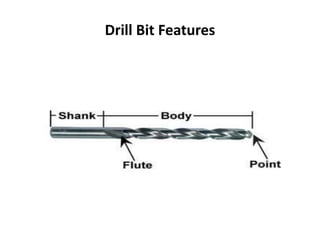

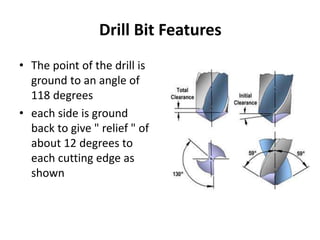

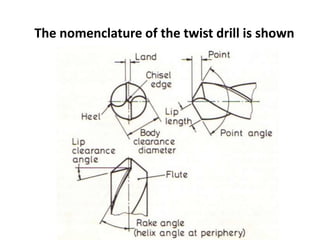

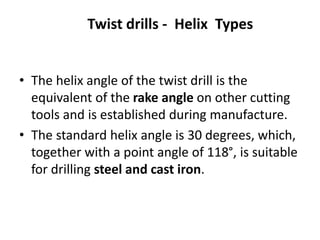

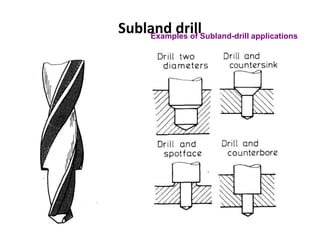

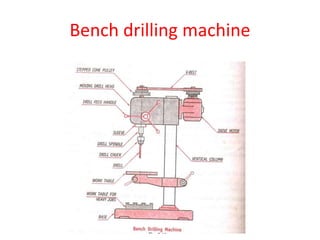

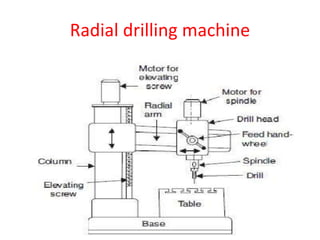

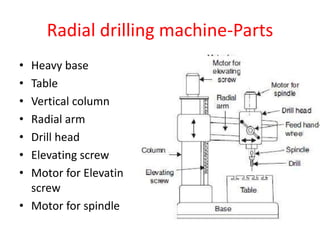

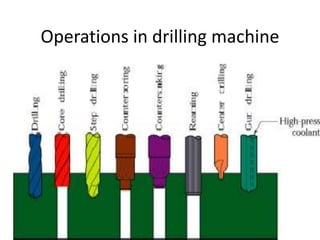

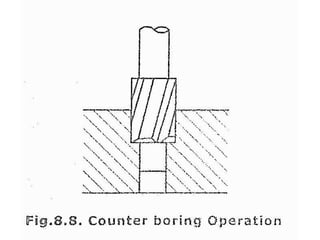

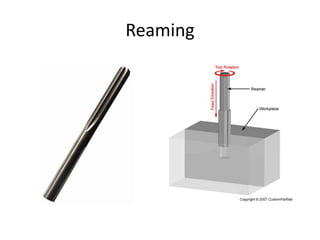

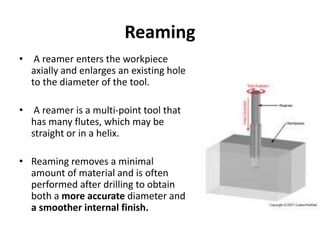

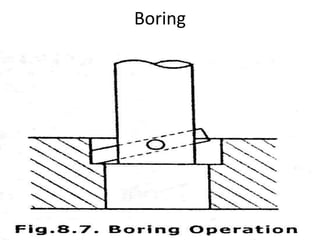

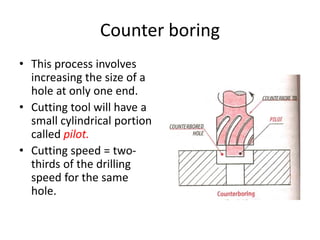

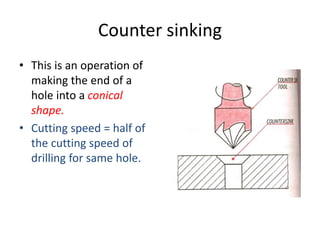

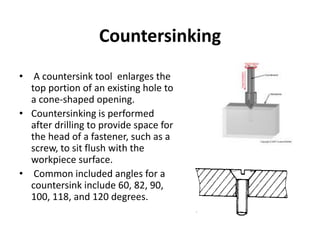

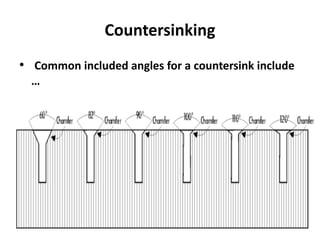

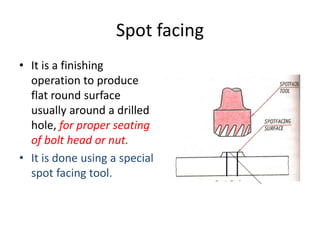

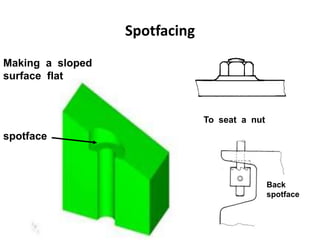

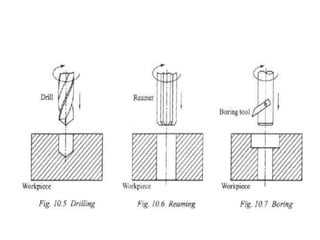

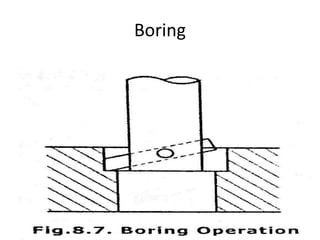

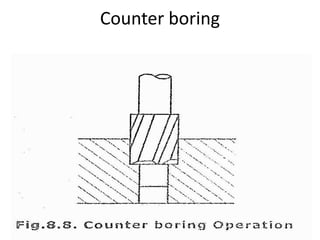

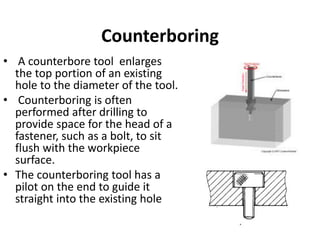

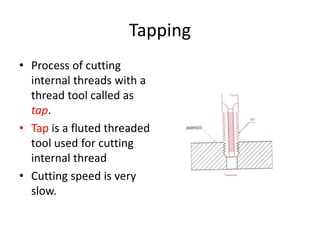

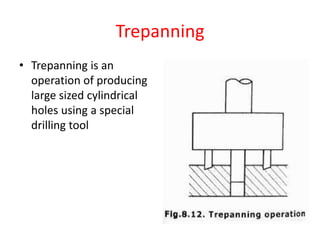

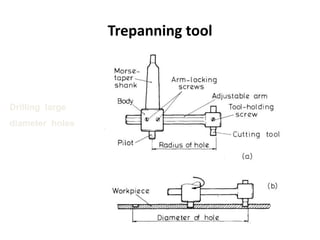

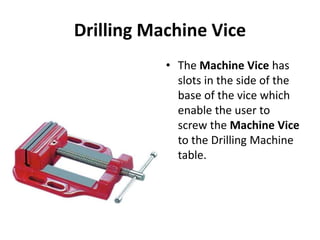

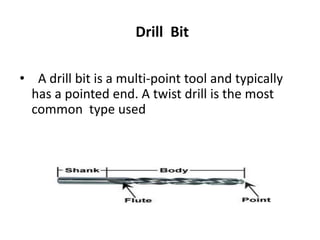

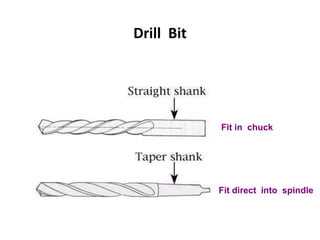

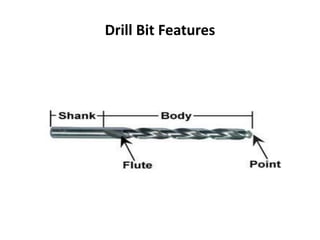

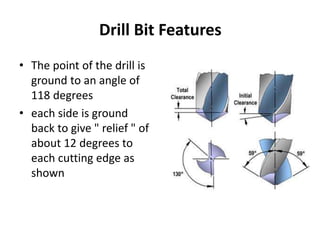

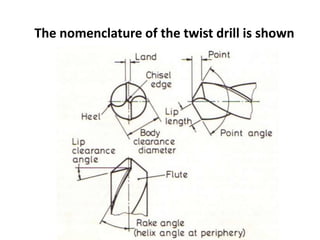

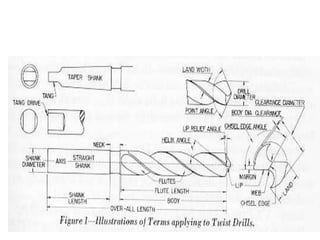

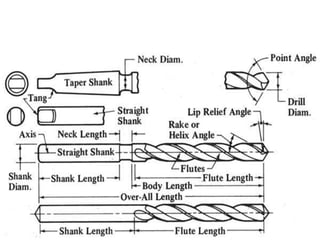

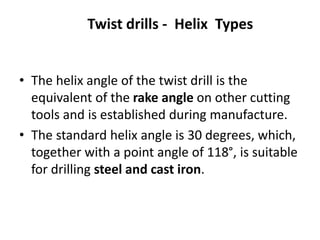

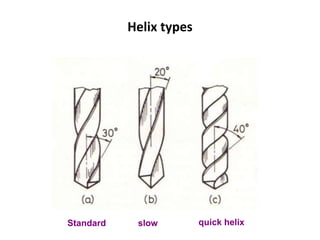

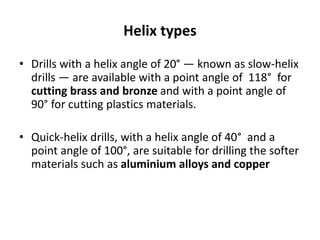

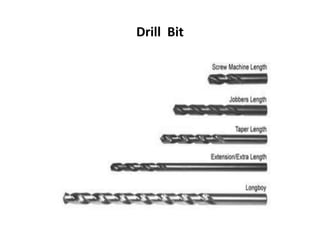

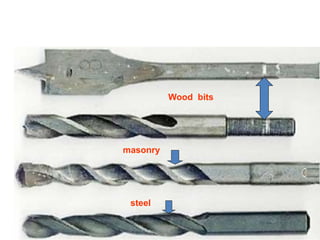

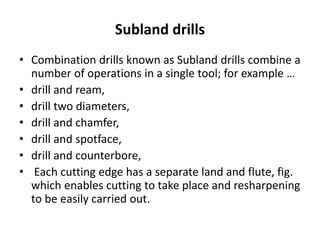

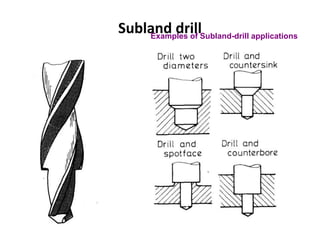

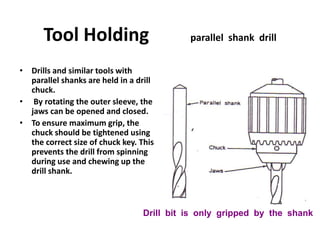

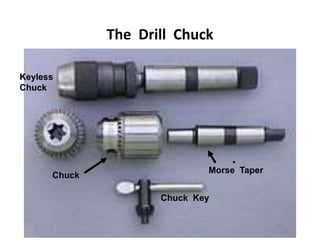

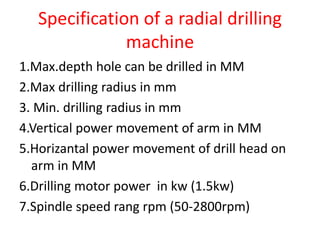

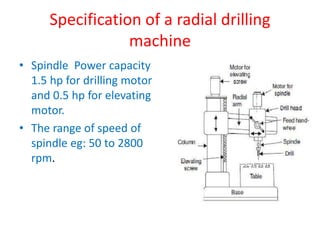

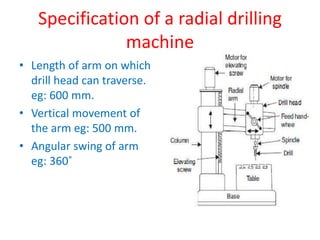

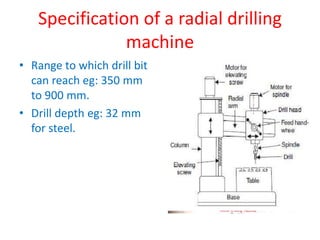

The document discusses drilling machines and drilling operations. It describes the main components and functions of drilling machines like bench drilling machines and radial drilling machines. It explains drilling tool components like drill bits and twist drills. It also covers other drilling operations like reaming, boring, counterboring, countersinking, spot facing and tapping that can be done on drilling machines. Safety precautions for operating drilling machines are also mentioned.