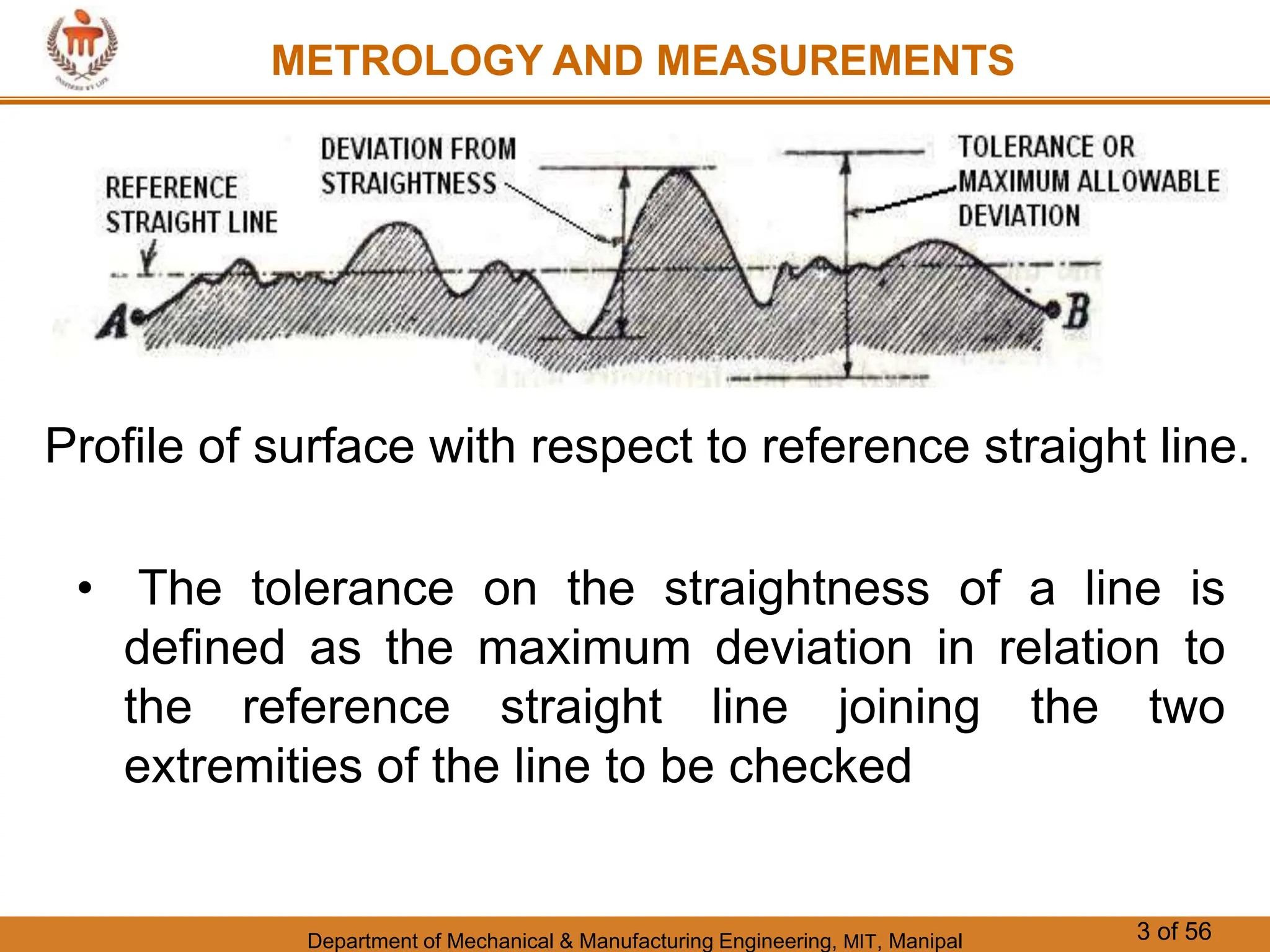

The document discusses various methods for measuring form errors, specifically straightness, including using a spirit level, auto-collimator, and straight edge. It describes how to perform straightness tests using these instruments by dividing the test surface into sections and measuring angular deviations between sections. The document also provides steps for calculating and analyzing straightness measurement data, including determining deviations from both a reference straight line and a best fit line between endpoints.