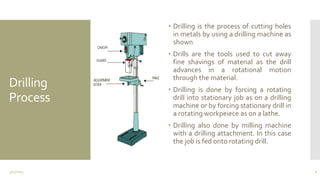

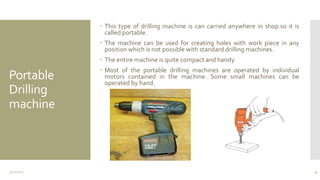

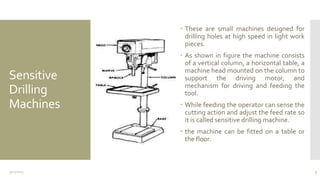

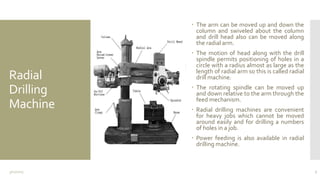

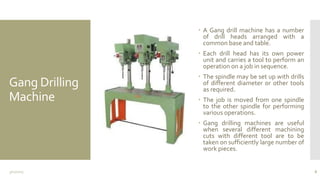

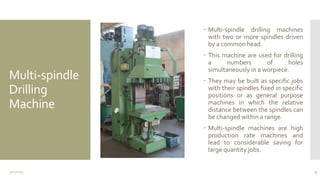

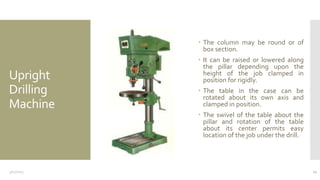

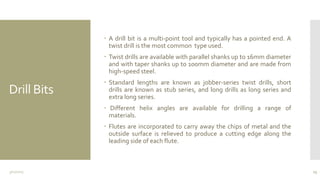

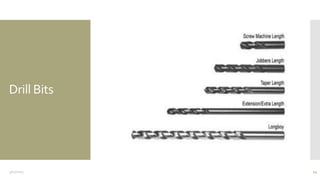

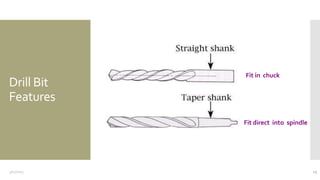

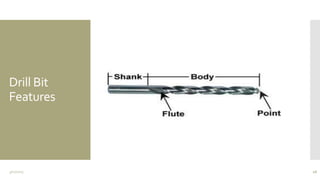

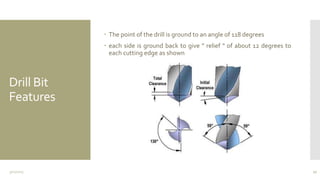

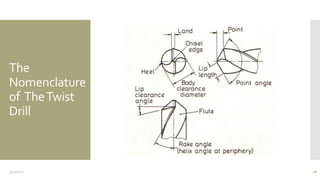

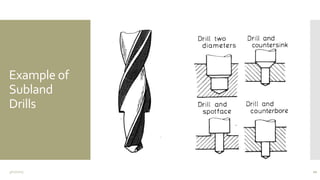

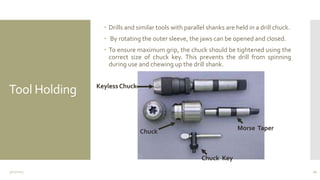

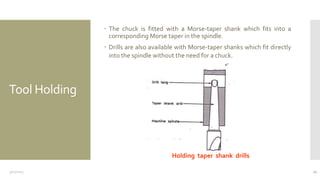

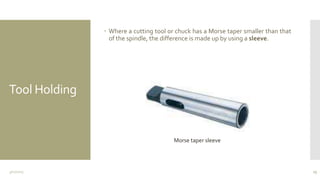

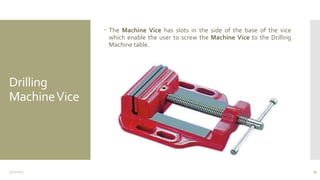

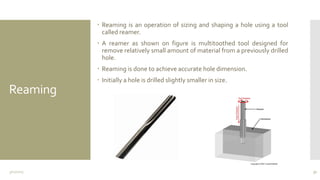

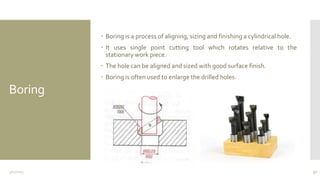

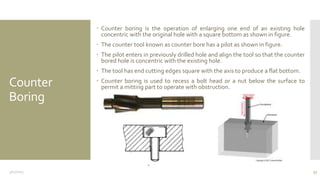

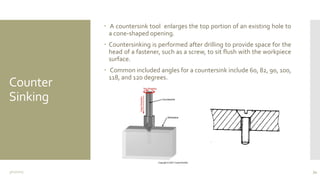

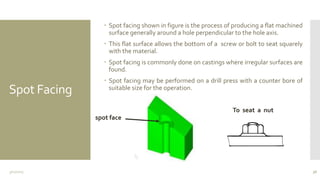

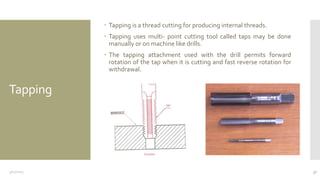

The document outlines the manufacturing process of drilling machines, detailing various types such as portable, sensitive, radial, gang, multi-spindle, automatic, and upright drilling machines. It also covers specifications of drilling machines, drill bits, tool holding mechanisms, and operations like drilling, reaming, and boring. Each section describes the functionalities and applications relevant to different drilling techniques and tools.