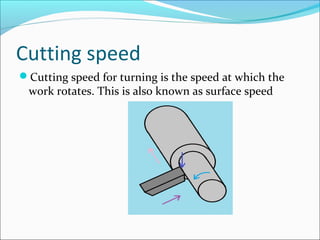

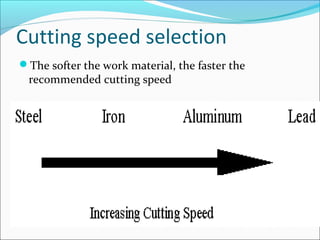

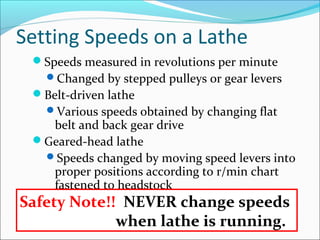

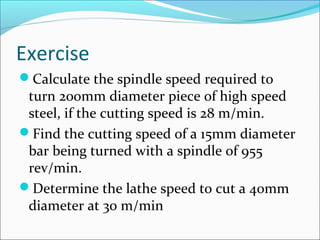

The document discusses the cutting speed for turning on a lathe, which is the speed at which the workpiece rotates and is crucial for effective machining processes. It outlines factors affecting cutting speed, including material hardness, tool rigidity, and machine conditions, as well as the method for setting speeds on different types of lathes. Additionally, it provides formulas for calculating both lathe cutting speed and spindle speed based on the diameter of the workpiece.