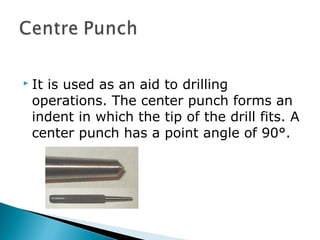

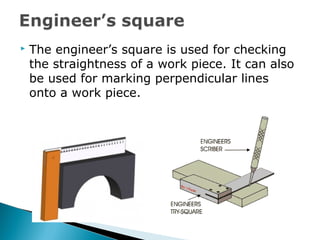

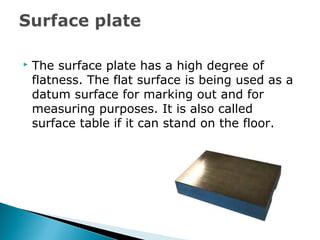

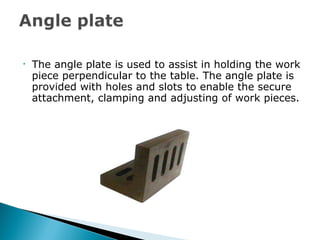

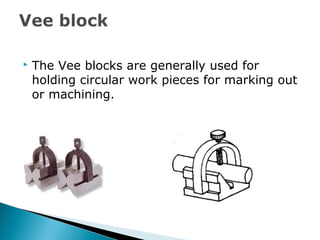

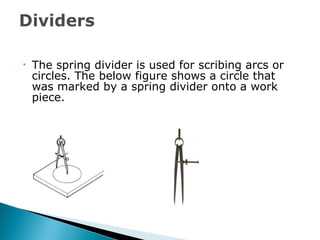

This document describes various tools used for marking out, which is the first step in the manufacturing process of transferring designs from drawings onto workpieces. It lists and provides details on common marking out tools such as scribes, marking blue, punches, engineers squares, surface plates, surface gauges, angle plates, vee blocks, steel rules, dividers, and ball peen hammers; and explains their various purposes and uses in marking out metal and plastic workpieces.