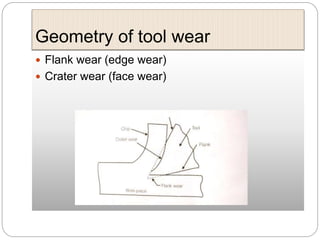

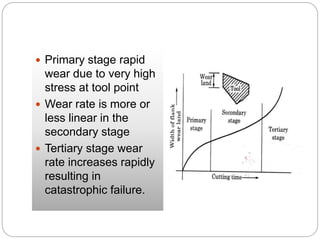

Tool life is measured by the time period from when a tool starts cutting until failure or until it needs resharpening. Tool life can be measured in units of time, number of pieces cut, volume of material removed, or length of cut. Tools typically fail due to high temperatures, mechanical impacts, or gradual wear. Wear occurs on the flank and crater faces of tools and is caused by abrasion, diffusion, electrochemical reactions, and other mechanisms. Factors like cutting speed, workpiece properties, tool geometry, and cooling influence tool life.