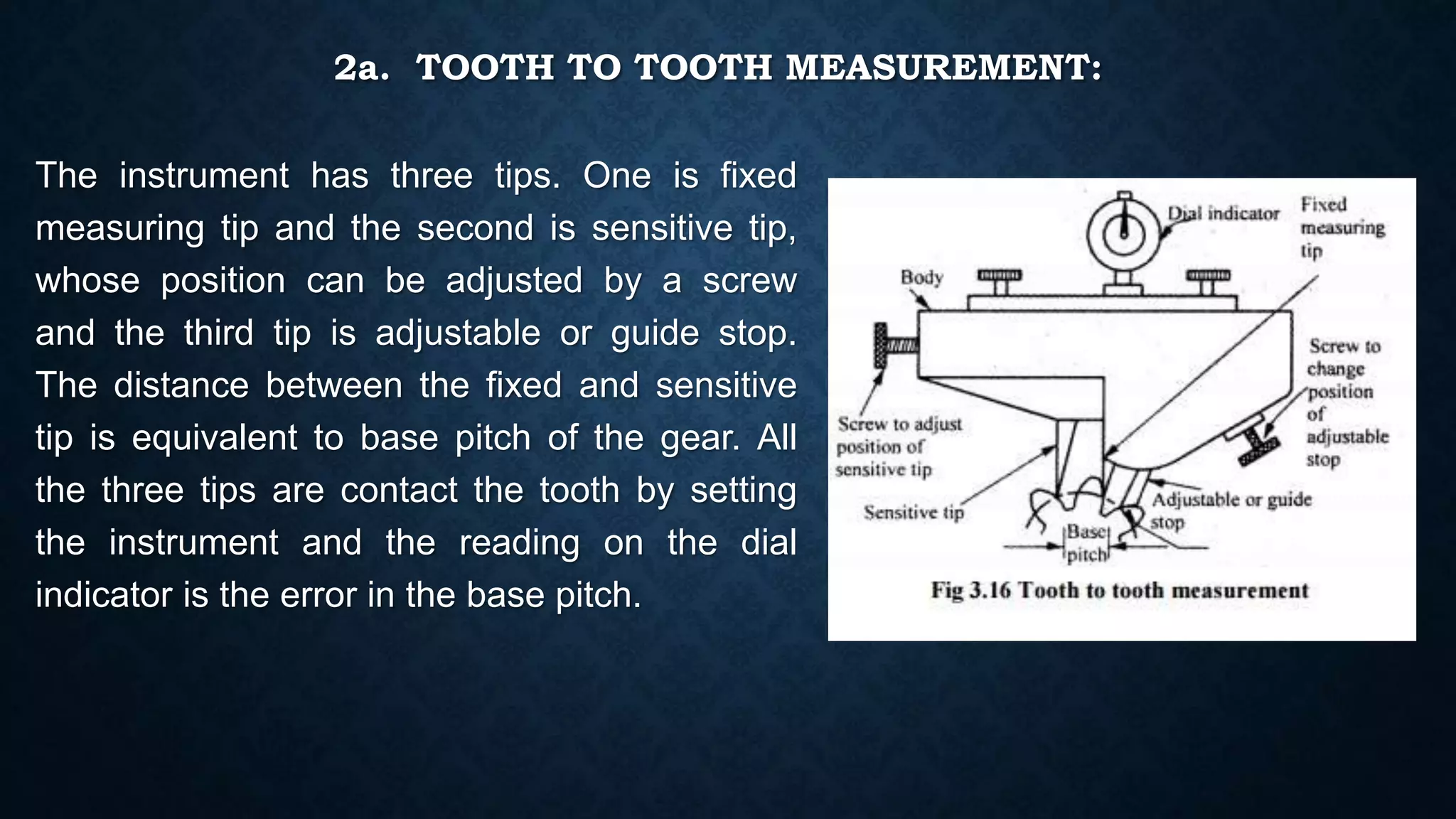

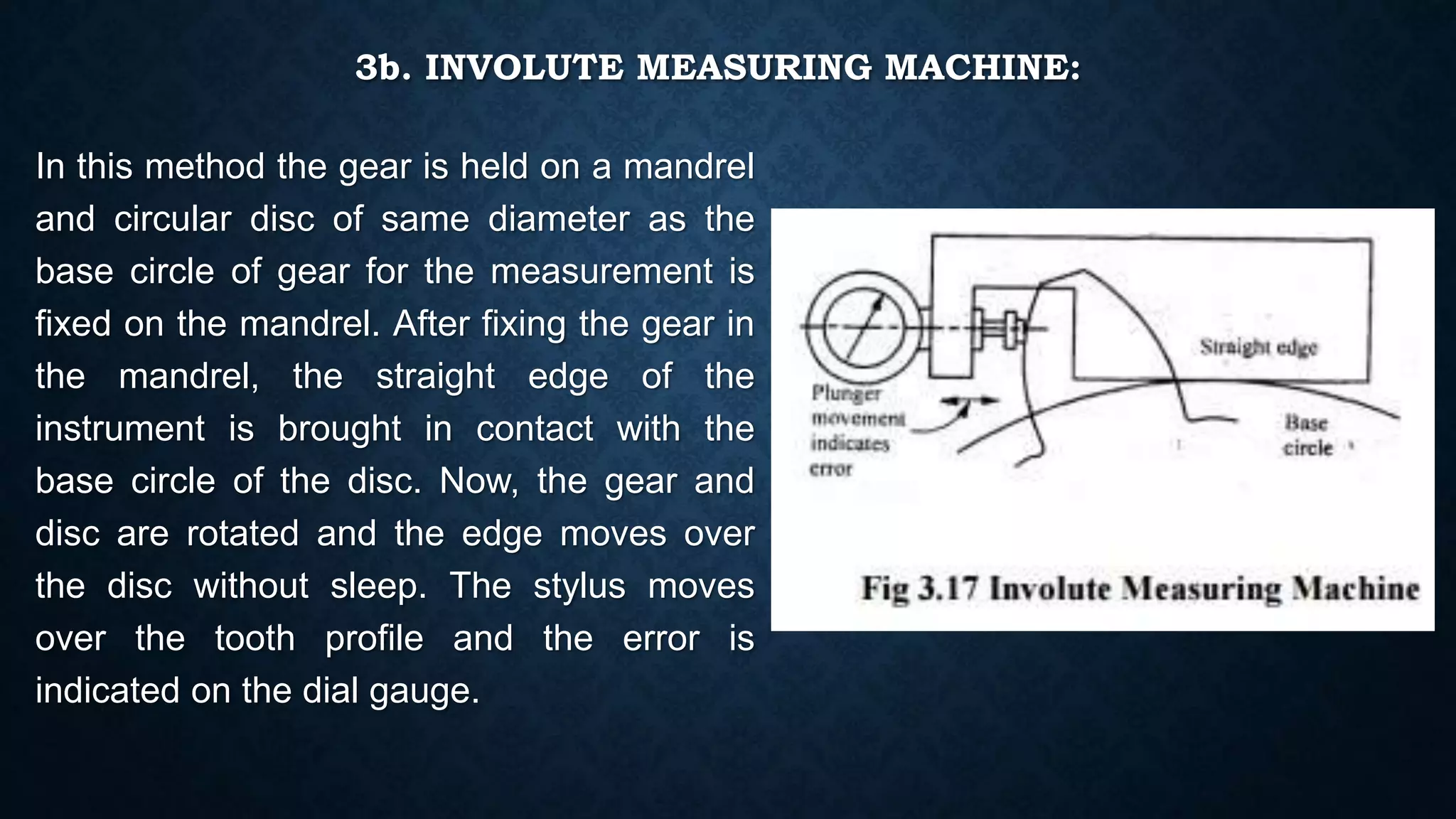

Gears are important machine elements used for power transmission between rotating shafts. There are several types of gears including spur gears, helical gears, bevel gears, and worm gears. Gears are precisely measured and inspected to evaluate factors such as pitch errors, runout, profile accuracy, and tooth thickness. Common inspection methods include using vernier calipers, comparators, and optical projection to analyze gear geometry and performance. Proper inspection is important for ensuring gears effectively transmit torque between components.