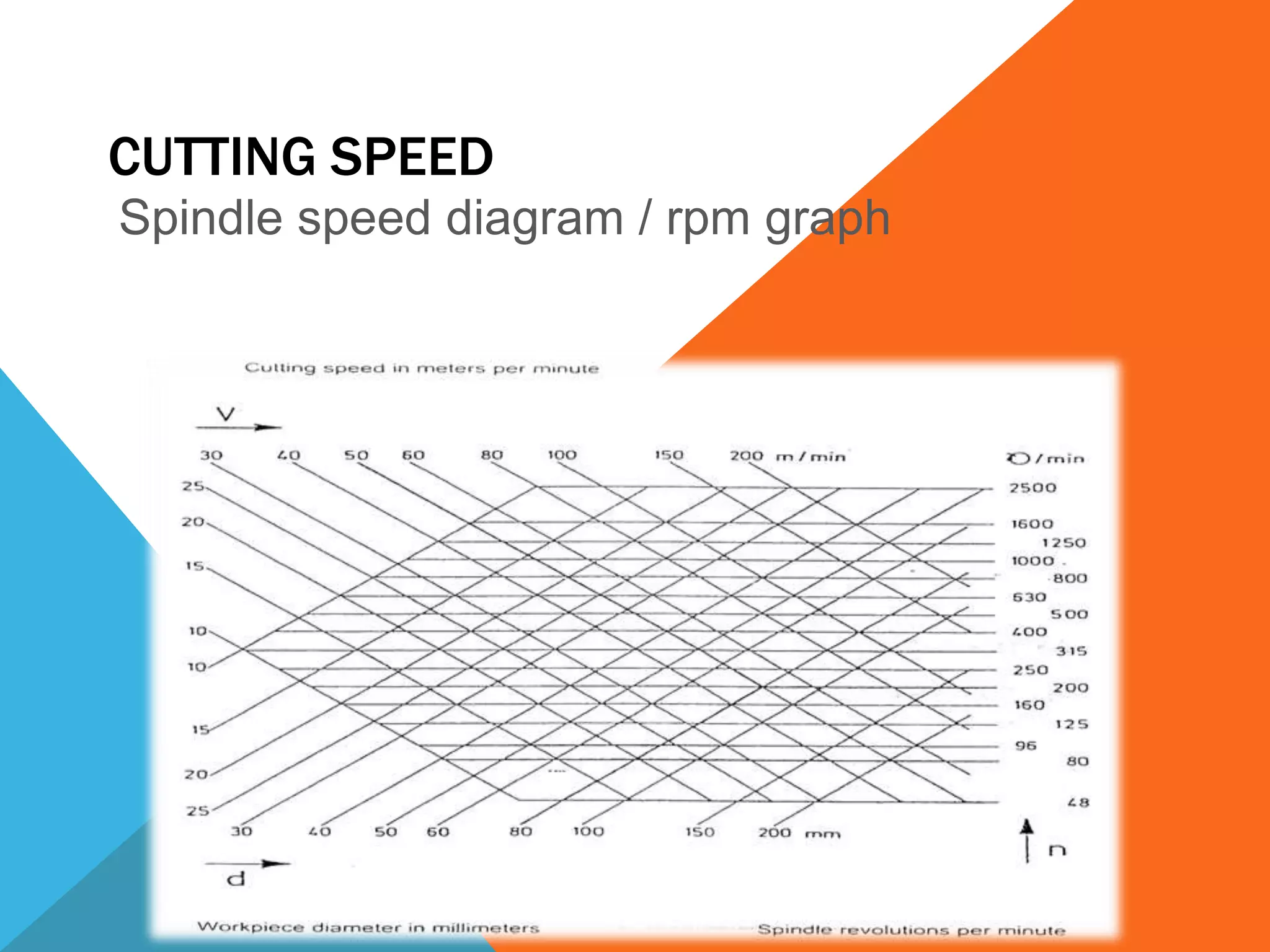

This document discusses cutting speed in machining processes. It states that selecting the correct cutting speed can save time and costs while also contributing to quality and surface finish. Maintaining the proper cutting speed helps tools last longer without needing frequent sharpening and maximizes machining without damaging tools or machines. Cutting speed depends on factors like workpiece diameter, depth of cut, feed rate, workpiece and tool material. Equations are provided to calculate spindle speed based on cutting speed and diameter. Machining time can be determined based on the original and final diameters, depth of cut, spindle speed, feed rate, workpiece length, and cutting speed.

![CUTTING SPEED

Basic factor in Turning

THE FACTORS:

V = CUTTING SPEED IN METRE PER MINUTE

[M/MIN]

N = SPEED OF WORK (SPINDLE SPEED) IN

REVOLUTION PER MINUTE [REV/MIN]

D

Π

= DIAMETER OF THE WP IN MILLIMETRE [MM]

= C O N S TA N T 3 . 1 4 2

R E L AT I O N B E T W E E N T H E FA C T O R S :](https://image.slidesharecdn.com/chapter5cuttingspeed-131031112203-phpapp01/75/cutting-speed-4-2048.jpg)

![CUTTING SPEED

Machining Time

D0 = Original / initial diameter [mm]

l = Length of tool travelled

D1 = New / final diameter [mm]

F = Feed [mm/rev]

d = Depth of cut [mm]

Fr = Feed rate [m/min]

N = Spindle speed [rev/min]

V = Cutting speed [m/min]

L = Length of the workpiece

T = Time taken by the tool [min]](https://image.slidesharecdn.com/chapter5cuttingspeed-131031112203-phpapp01/75/cutting-speed-9-2048.jpg)

![CUTTING SPEED

Machining Time

The turning operation reduces the diameter of the workpiece

from D0 to the final diameter D1. The Change in diameter is

determined by the depth of cut, d:

D0 - D1 = d [mm]

The feed in turning can be converted to a linear travel rate in

mm/min by the formula:

Fr = N · F [mm/min]

The time to machine from one end to required length is

given by:

T = l / Fr [min]](https://image.slidesharecdn.com/chapter5cuttingspeed-131031112203-phpapp01/75/cutting-speed-10-2048.jpg)