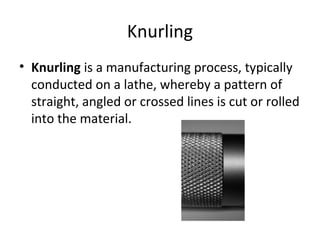

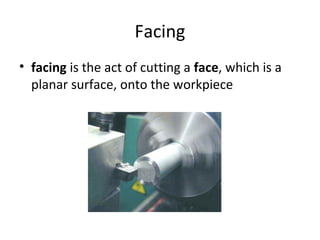

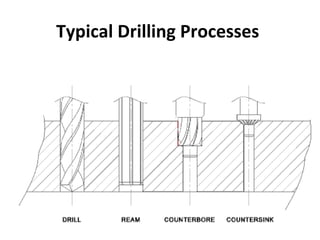

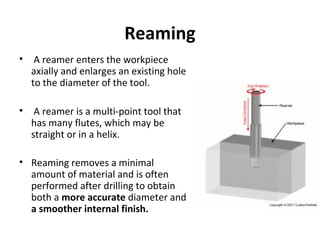

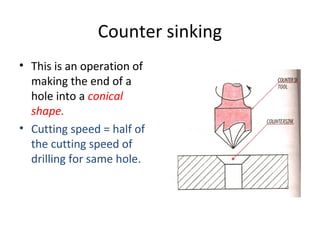

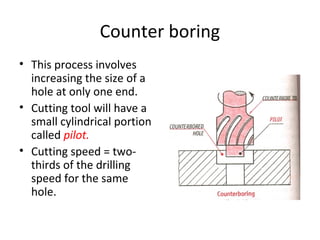

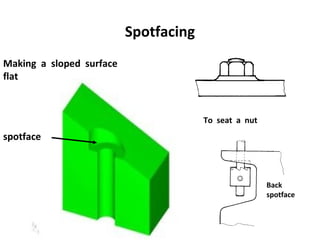

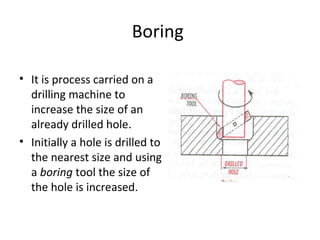

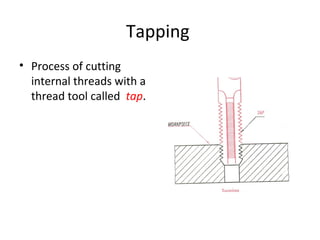

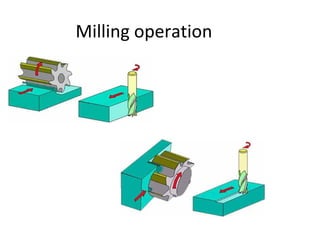

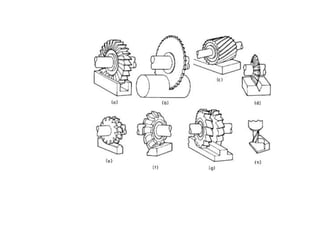

This document summarizes common machine operations performed by lathe machines, drill presses, and milling machines. Key operations of lathe machines include turning, knurling, drilling/boring, and facing. Drill presses are used for drilling, reaming, boring, counterboring, countersinking, tapping, and spotfacing. Milling machines are employed for face milling, end milling, keyway cutting, dovetail cutting, T-slot cutting, gear cutting, drilling, boring, and jig boring. Videos and descriptions of techniques like turning, knurling, drilling, and reaming are provided.