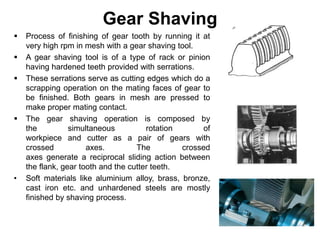

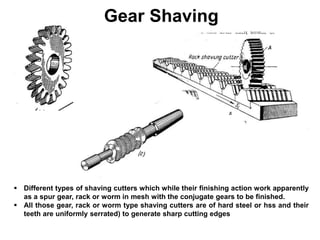

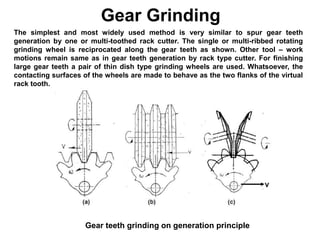

The document discusses various gear finishing processes such as gear shaving, rolling, grinding, honing, lapping, and finishing techniques like blast finishing and shot peening, detailing their functions, advantages, and limitations. It emphasizes the importance of accurate tooth profiles for optimal gear performance and explores the cost-effectiveness and productivity of different methods, particularly in automotive applications. Additionally, it covers surface treatments like phosphate coating for corrosion resistance and improved lubrication.