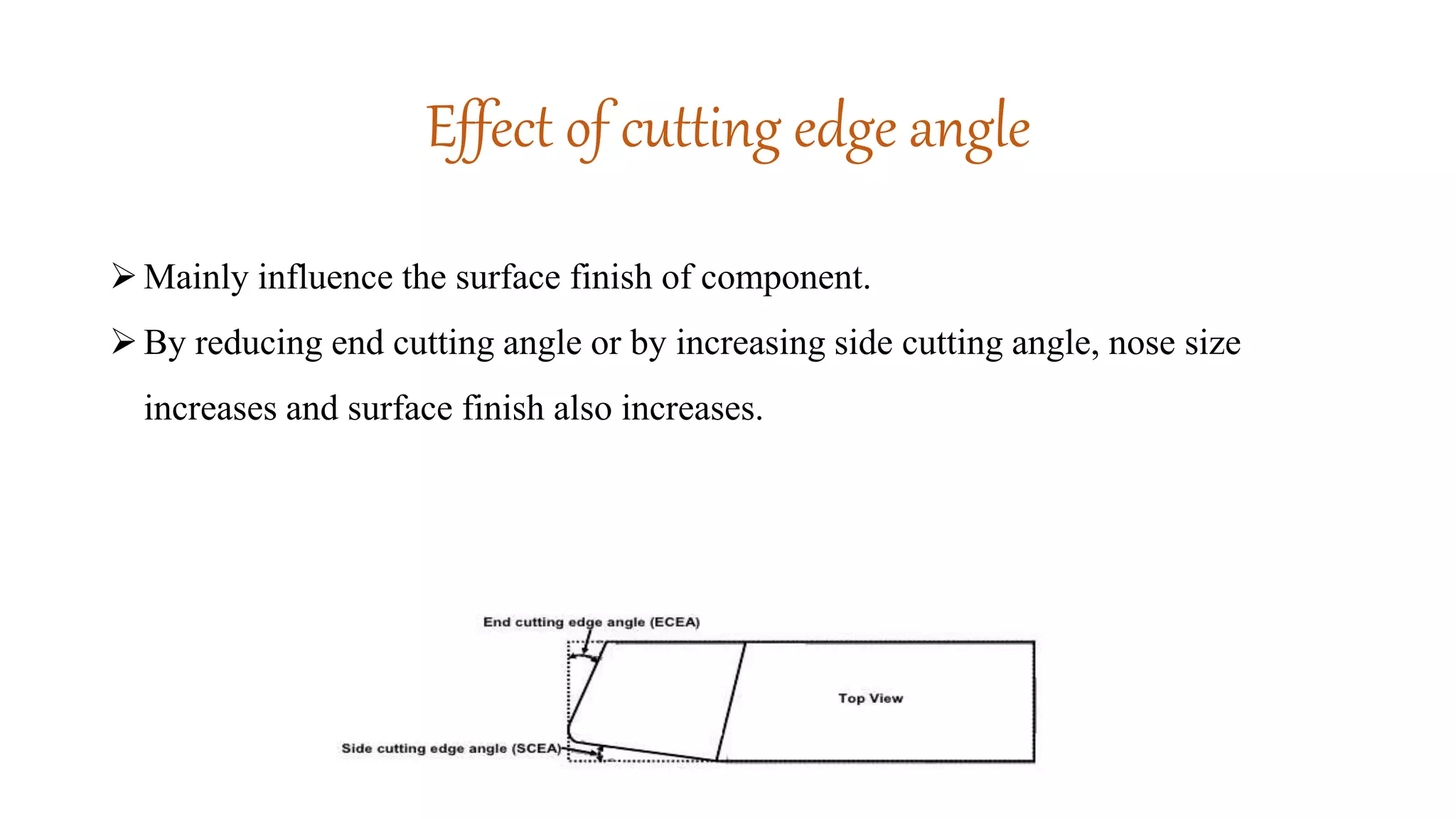

This document discusses single point cutting tools. It describes the types of tools, tool geometry including angles and designations. It explains the effects that varying the back rake angle, side rake angle, relief angle, cutting edge angle, and nose radius have on machining. Finally, it lists common tool materials and provides brief conclusions and references.