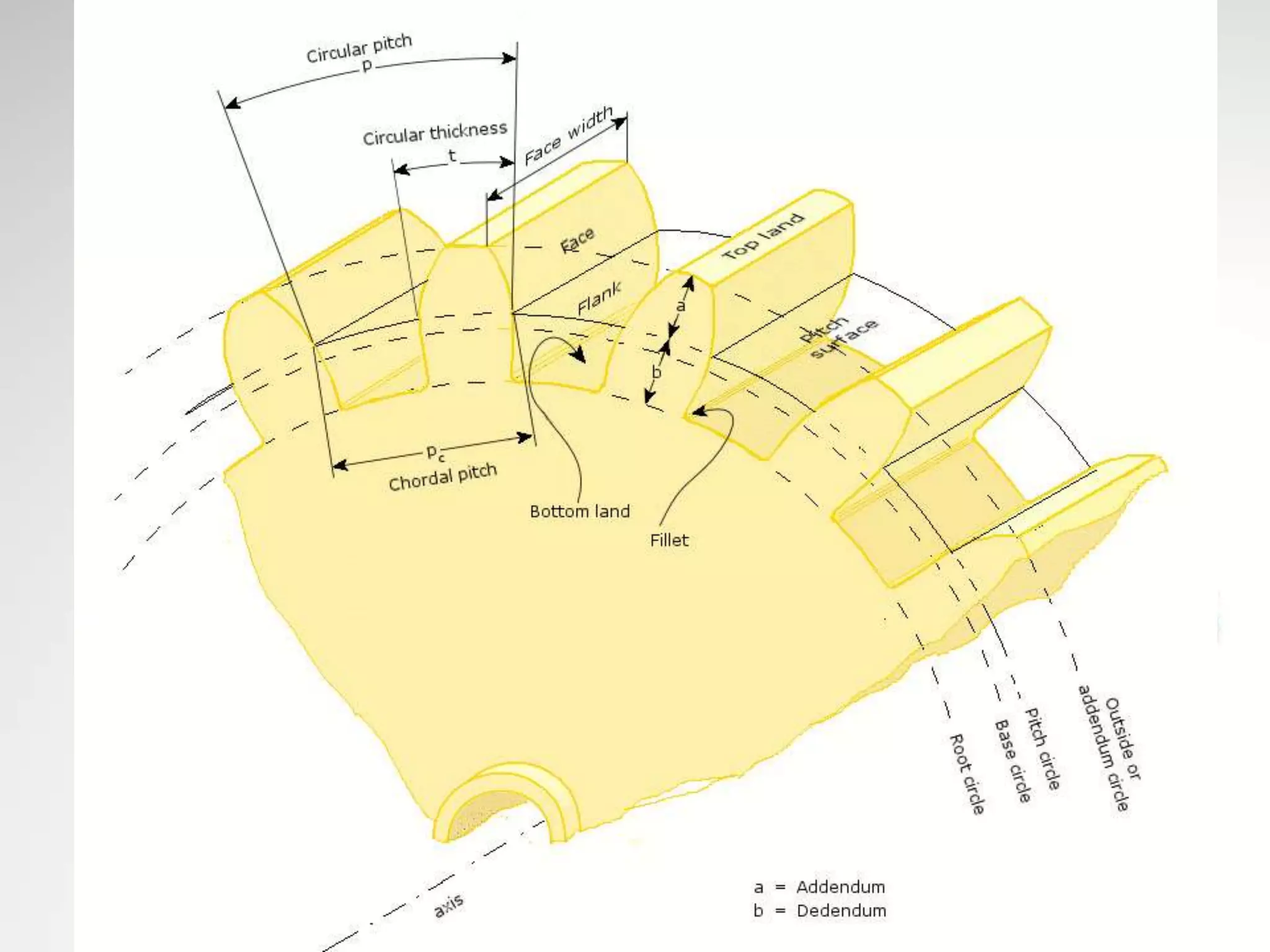

This document defines key terminology used in gear calculations, including:

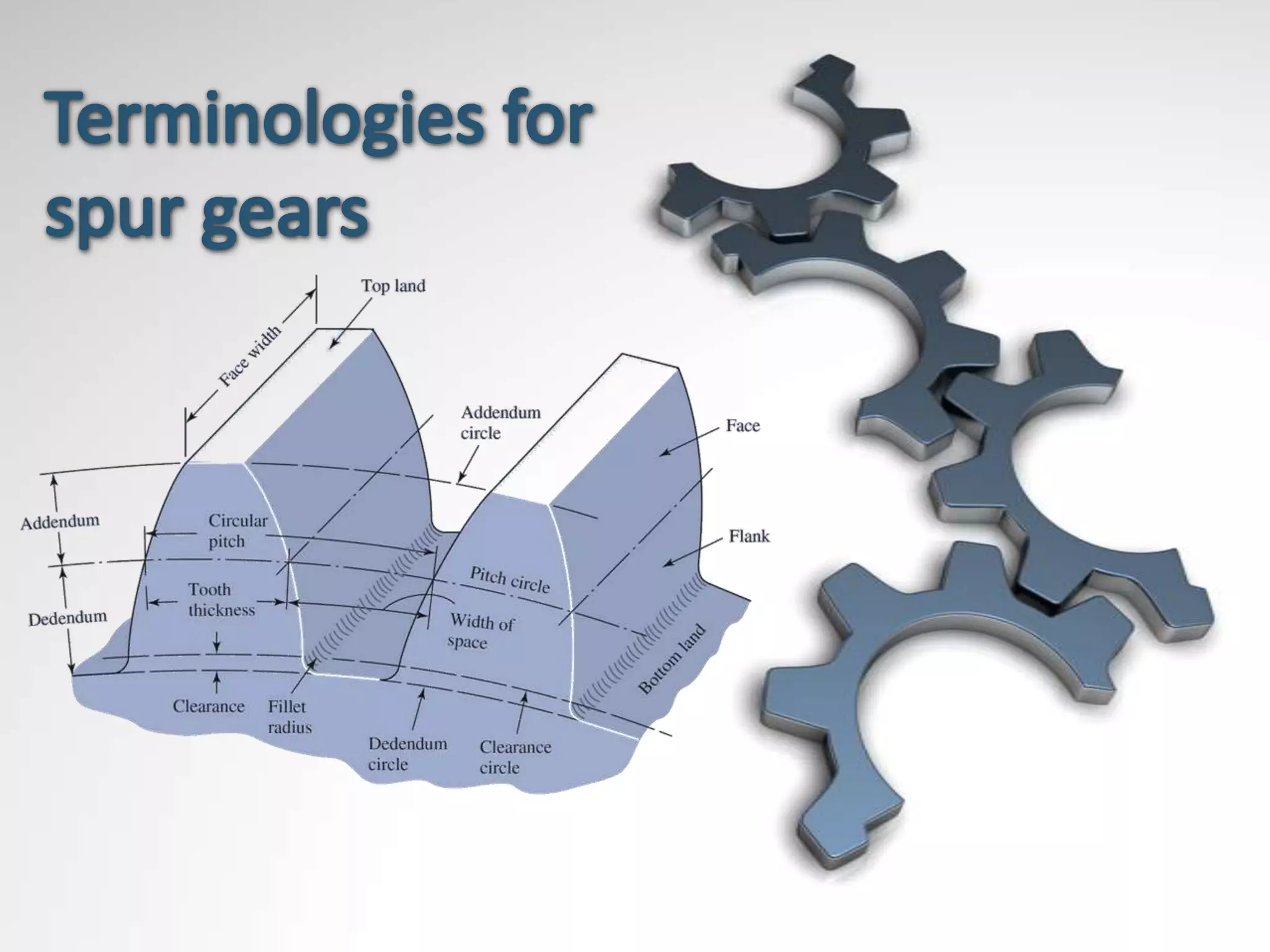

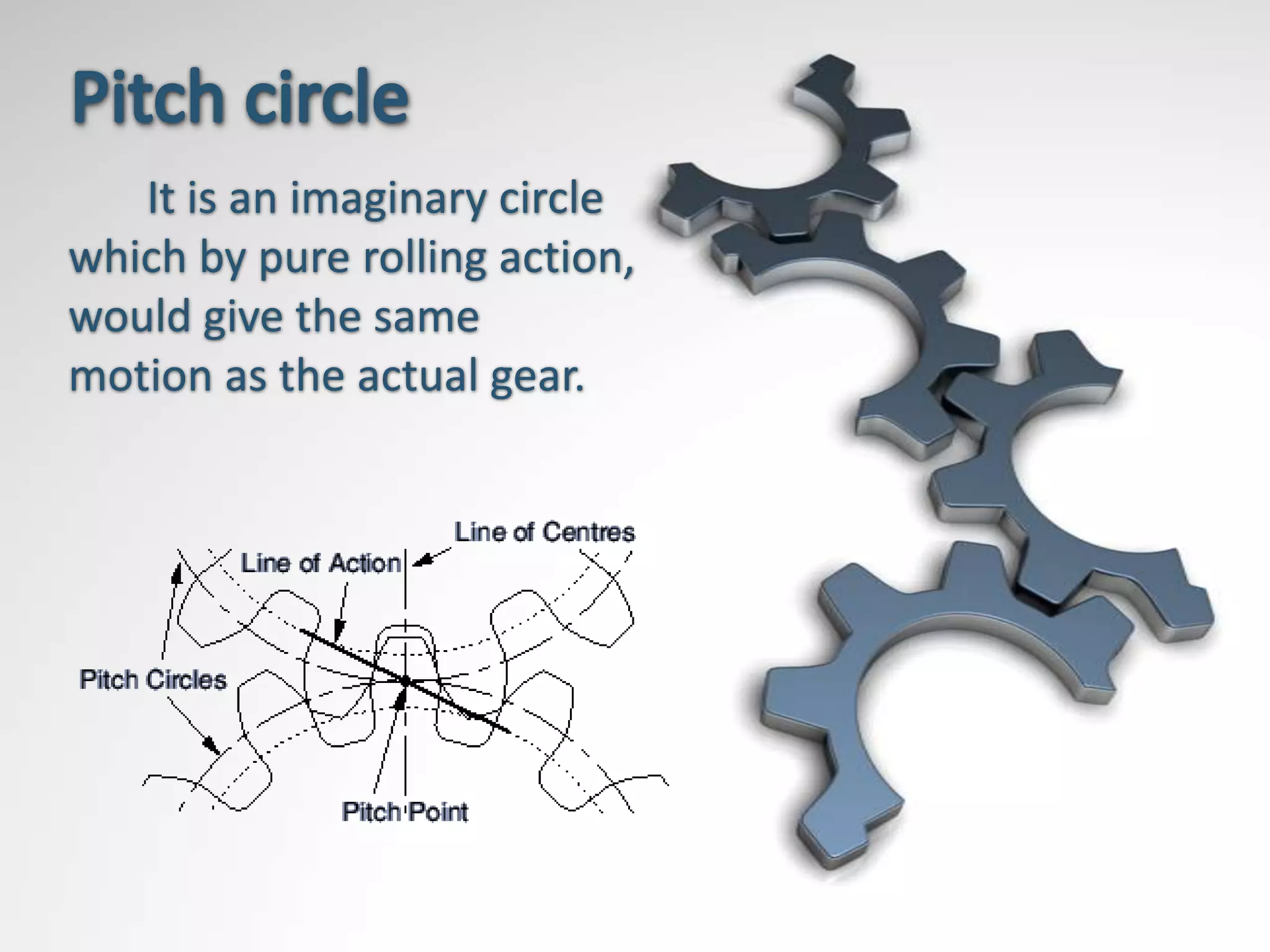

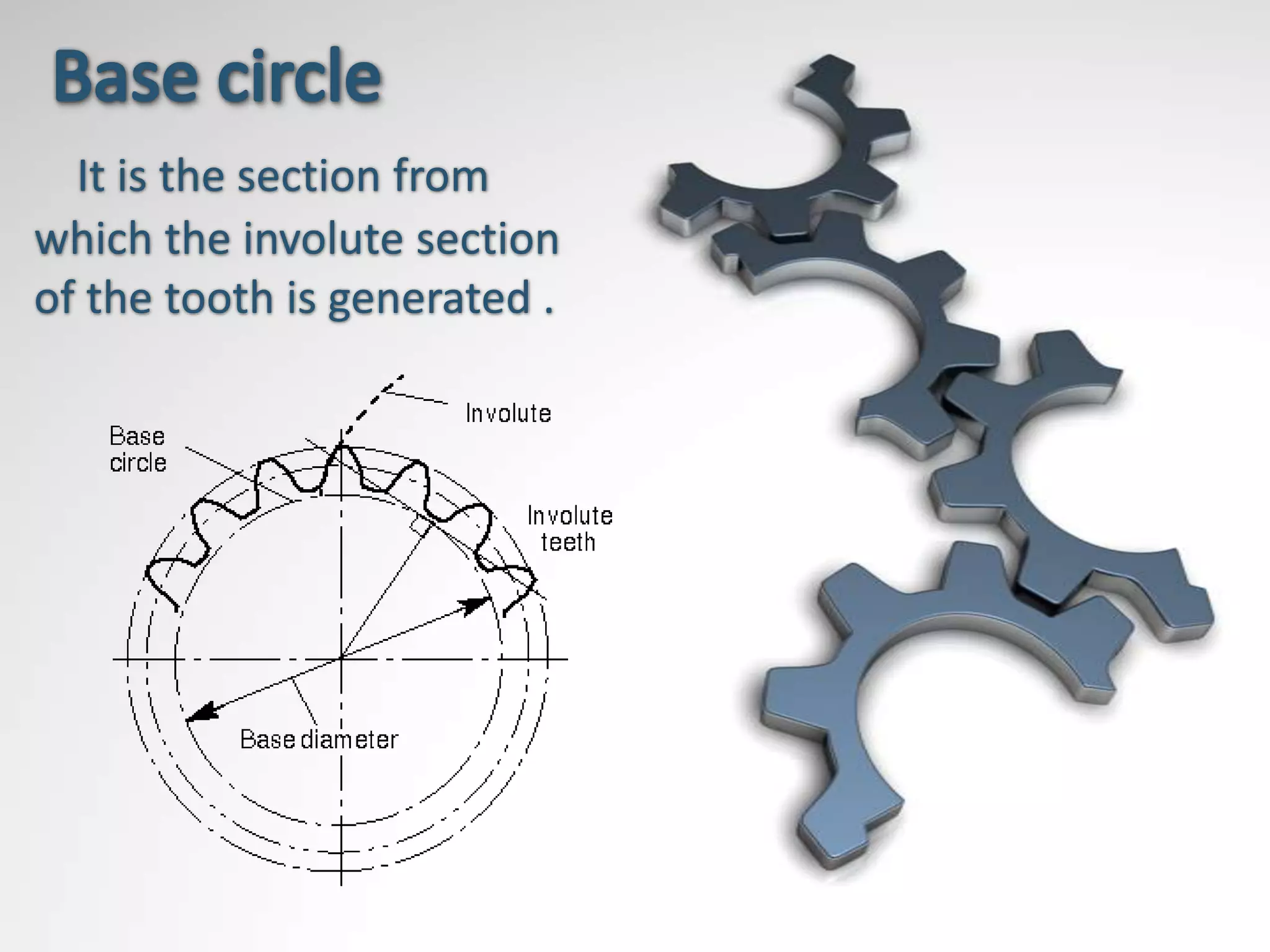

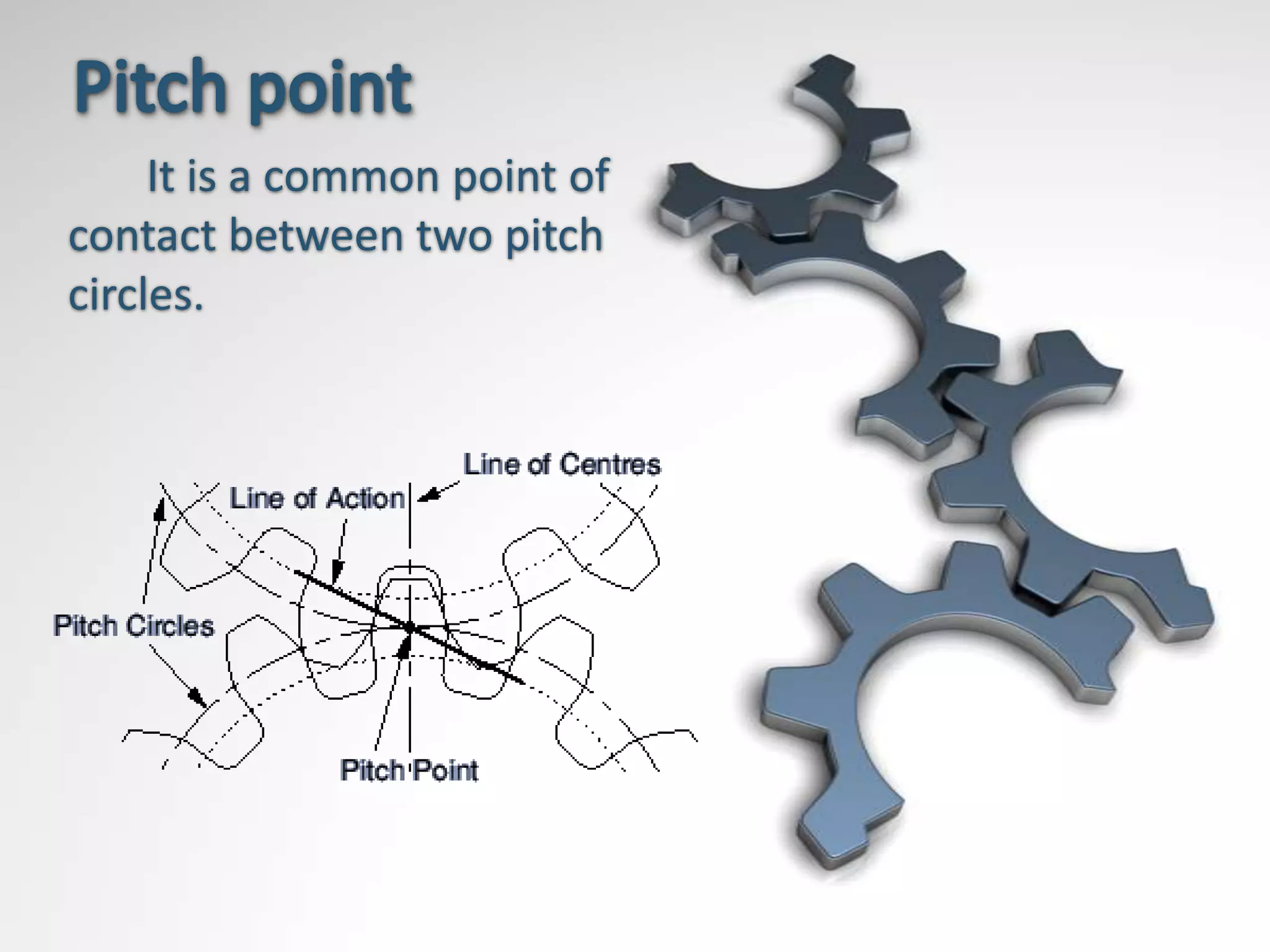

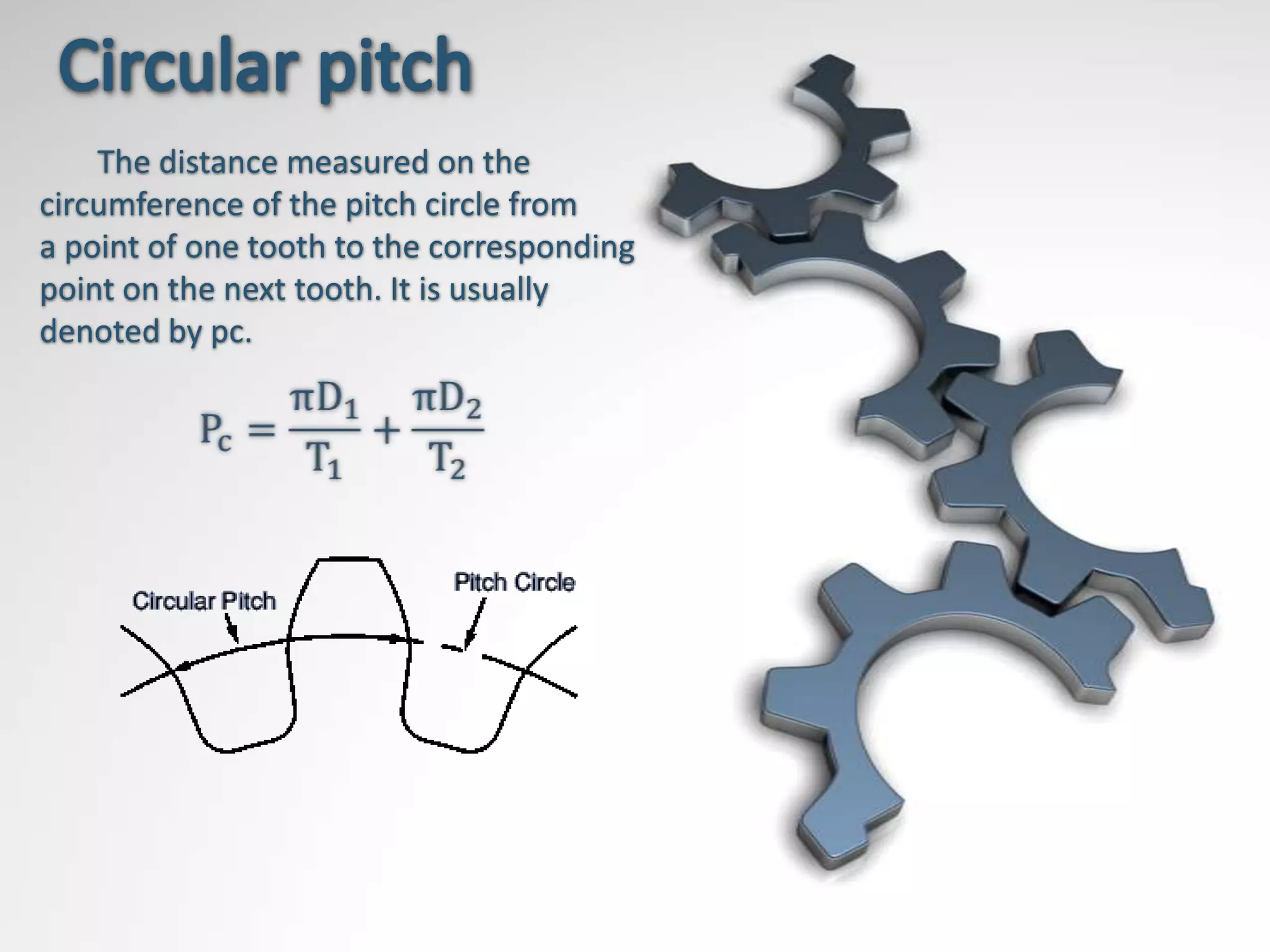

- Pitch circle - An imaginary circle used to define gear size and motion

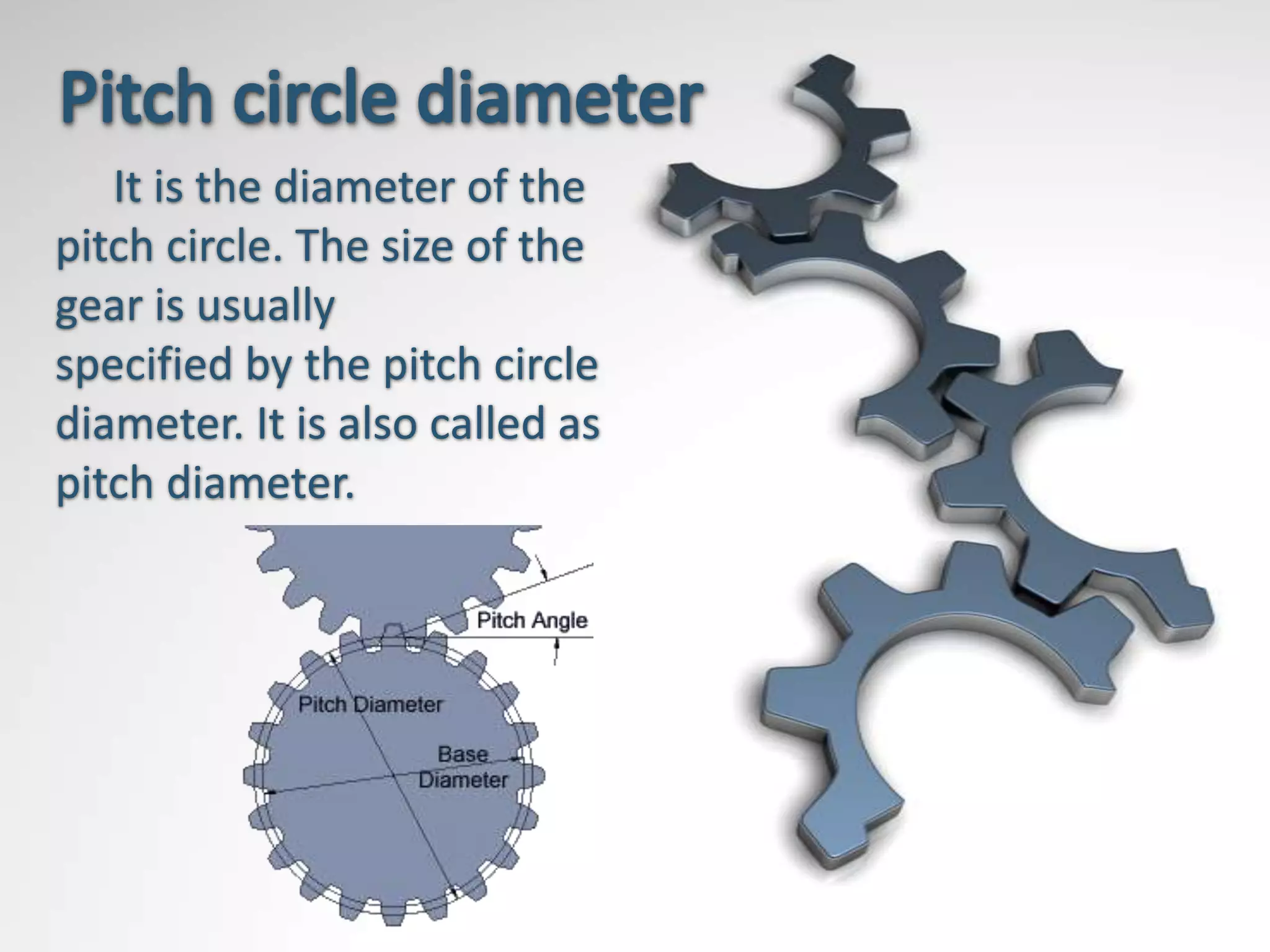

- Pitch diameter - The diameter of the pitch circle

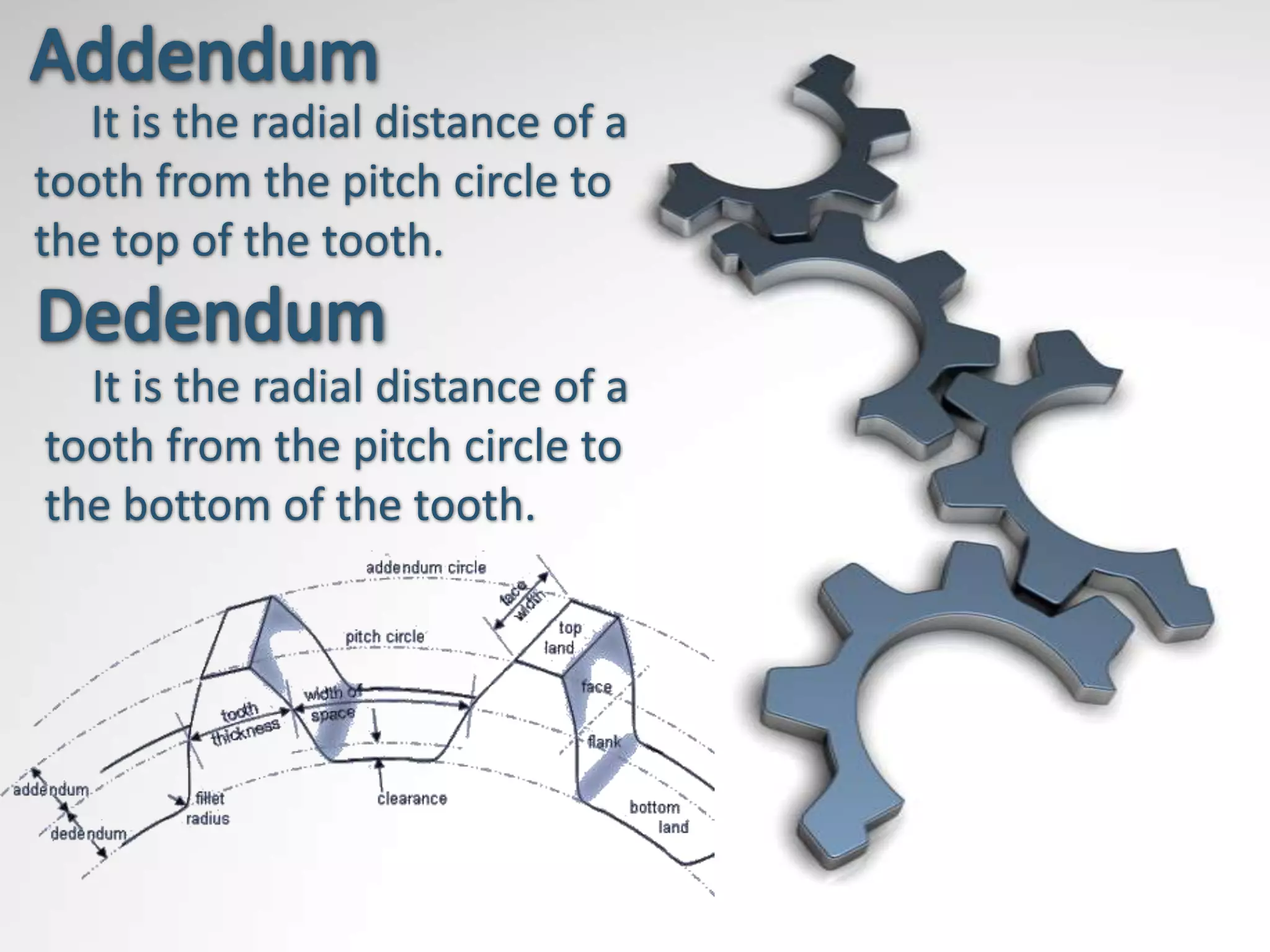

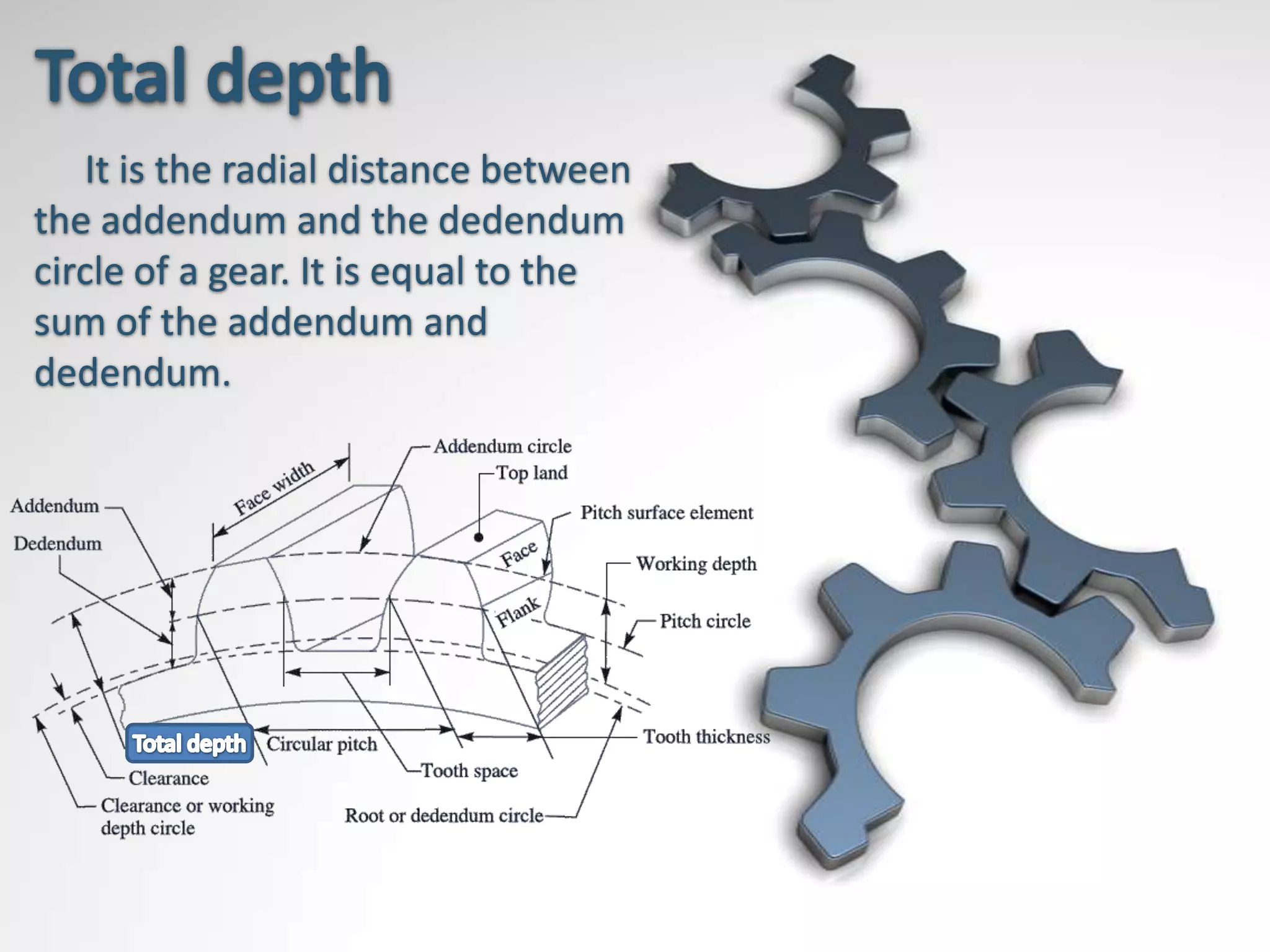

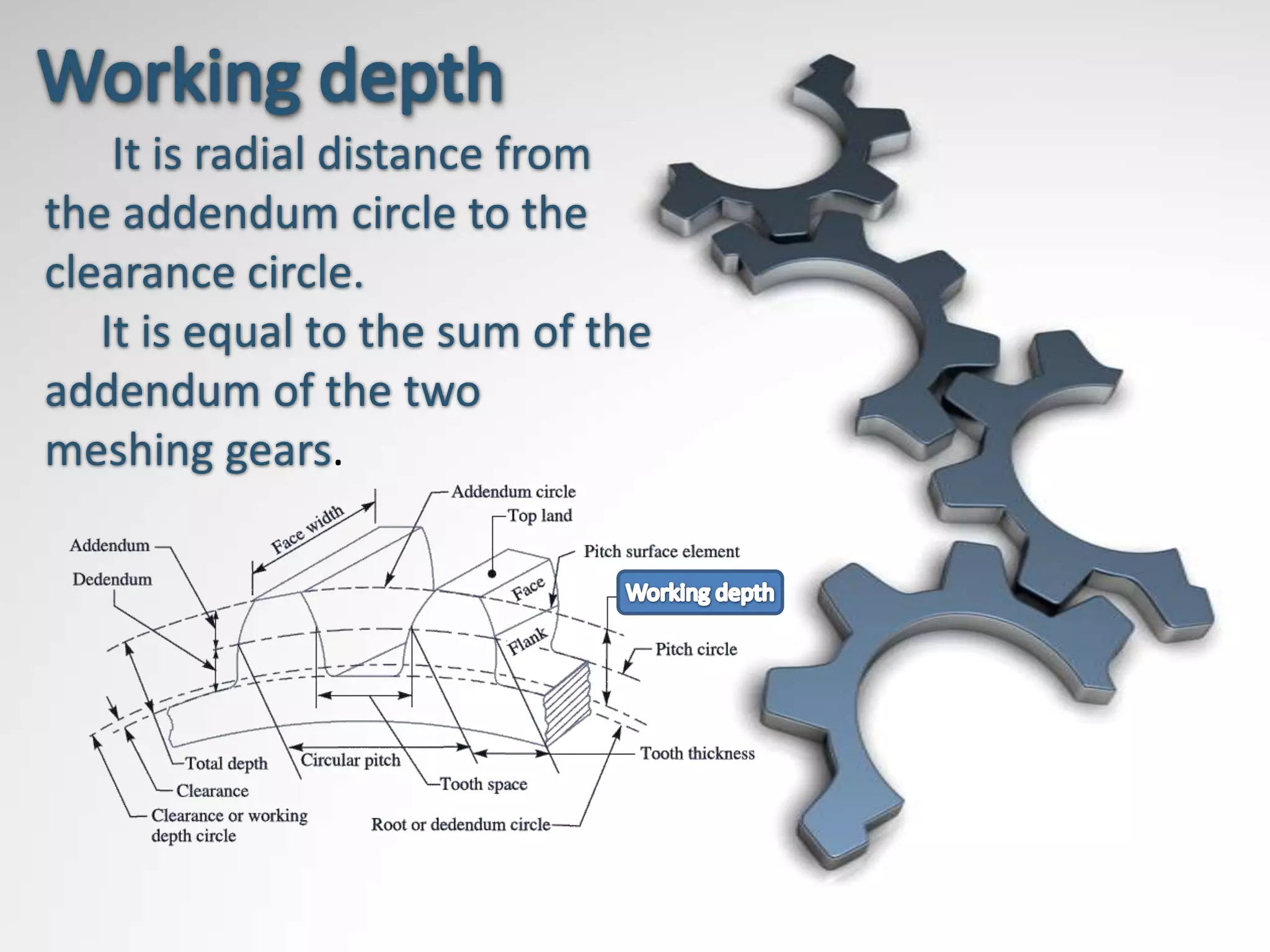

- Addendum - The radial distance from the pitch circle to the top of the tooth

- Dedendum - The radial distance from the pitch circle to the bottom of the tooth

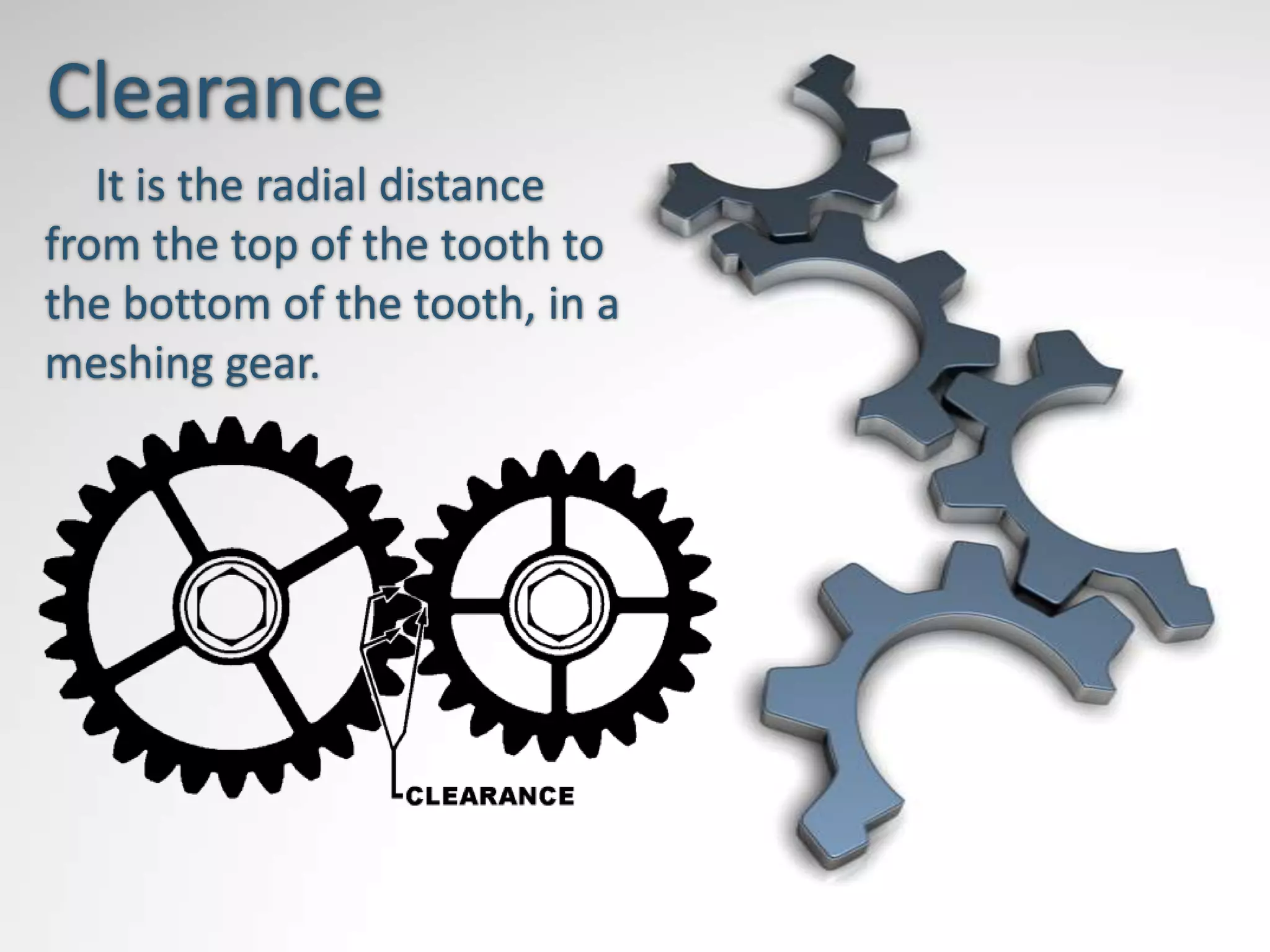

- Clearance - The radial distance between the top of one tooth and bottom of the other in mesh