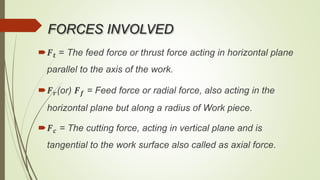

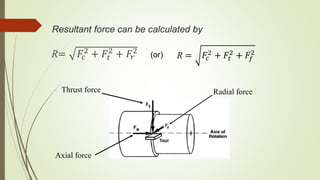

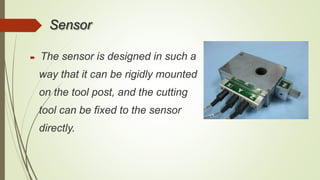

The document discusses the design and functionality of a lathe tool dynamometer used for measuring cutting forces in machining operations, emphasizing the importance of understanding these forces for economic manufacturing. It details various types of dynamometers and the principles behind their operation, including methodology for measuring cutting forces through strain gauges. The document highlights the necessity for dynamometers to have mechanical rigidity and sensitivity for accurate measurements while addressing challenges related to force measurement accuracy.