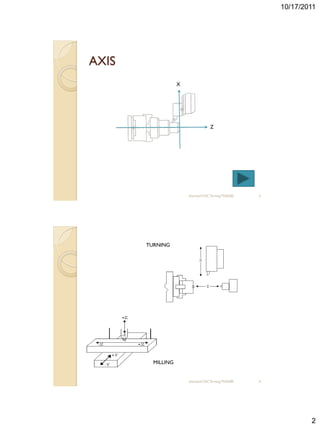

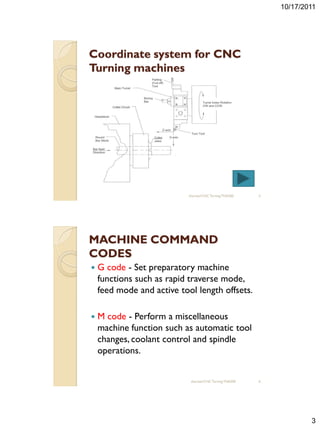

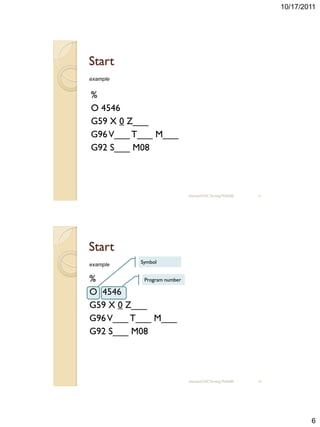

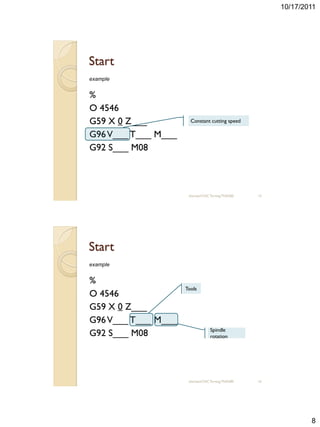

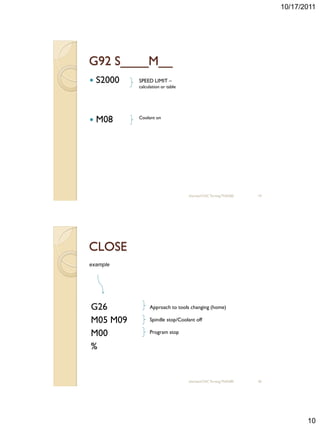

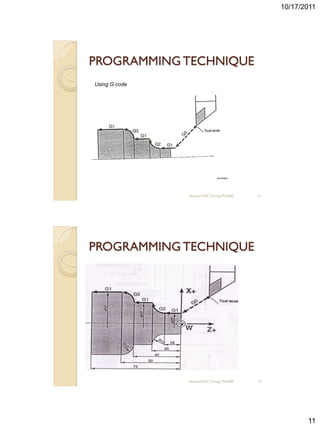

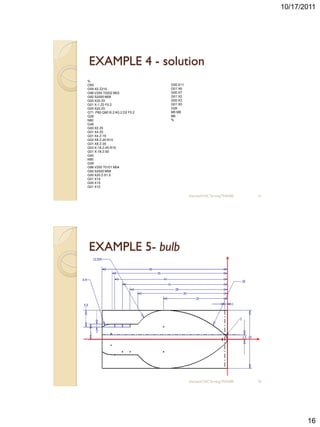

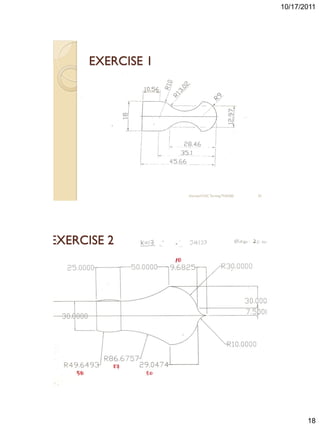

The document provides information about CNC turning processes using a TRAUB TNA 300 machine. It describes the machine axes and various cutting operations like turning and milling. It also explains coordinate systems and common G and M code commands used in CNC programs. Examples of full CNC turning programs are given to demonstrate programming techniques for roughing, cutting and finishing operations. Finally, exercises are presented for students to practice writing their own CNC programs.