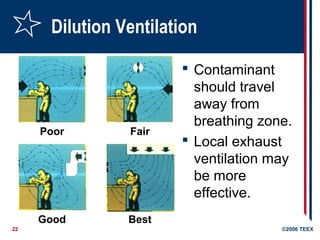

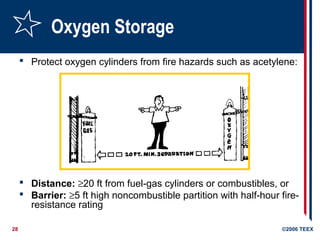

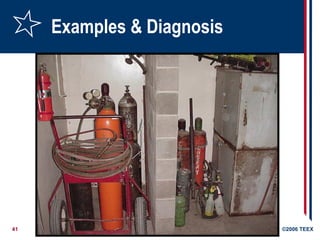

This document discusses welding hazards and safety regulations. It outlines fire, electric shock, explosion, and other hazards of welding operations. It describes three main types of welding - gas, arc, and oxygen/arc cutting. Regulations require fire prevention safeguards, special precautions for combustible materials, ventilation, protective equipment, and cylinder storage. Operators must be trained and supervisors responsible for fire watches, combustible removal, and authorizing safe work areas.