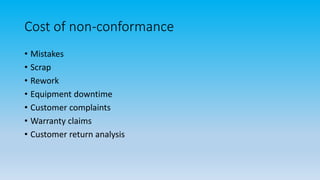

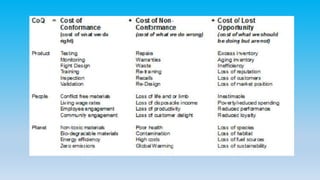

Crosby's philosophy defines quality as conformance to requirements. Quality is measurable and quantifiable rather than intangible. The goal is to meet requirements the first time to prevent defects and reduce costs. Crosby's four absolutes of quality are: 1) quality is defined by conformance to requirements, 2) prevention is preferable to inspection and cure, 3) the standard for quality is zero defects, and 4) quality is measured by the cost of non-conformance rather than defects. The principles of zero defects and "doing it right the first time" emphasize preventing defects to reduce costs associated with rework, scrap, and lost productivity.