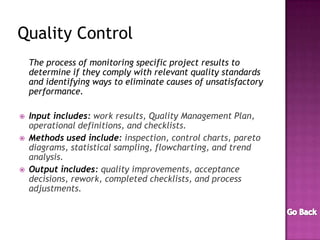

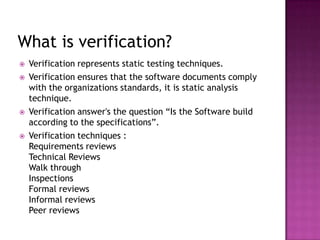

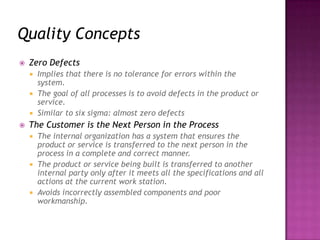

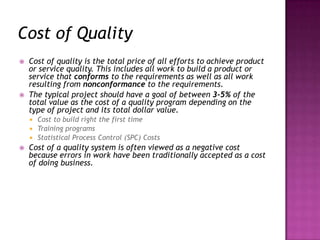

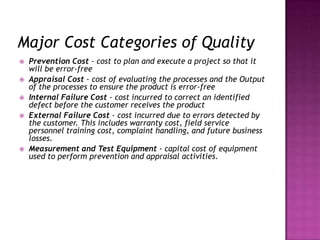

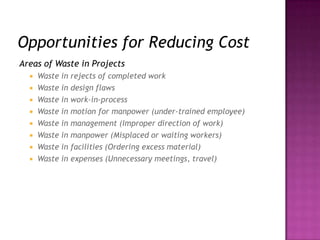

The document outlines the definition of quality and its importance in products and services, emphasizing goals such as customer satisfaction and conformance to requirements. It covers various quality management processes including quality planning, assurance, and control, as well as verification and validation techniques in software development. Additionally, it discusses total quality management principles, the cost of quality, and opportunities for reducing waste in projects.

![[ MBA - I ]

Presented By

Vishal Patel

Pooja Srivastawa](https://image.slidesharecdn.com/qualitymanagement-130908041343-/85/Quality-management-1-320.jpg)