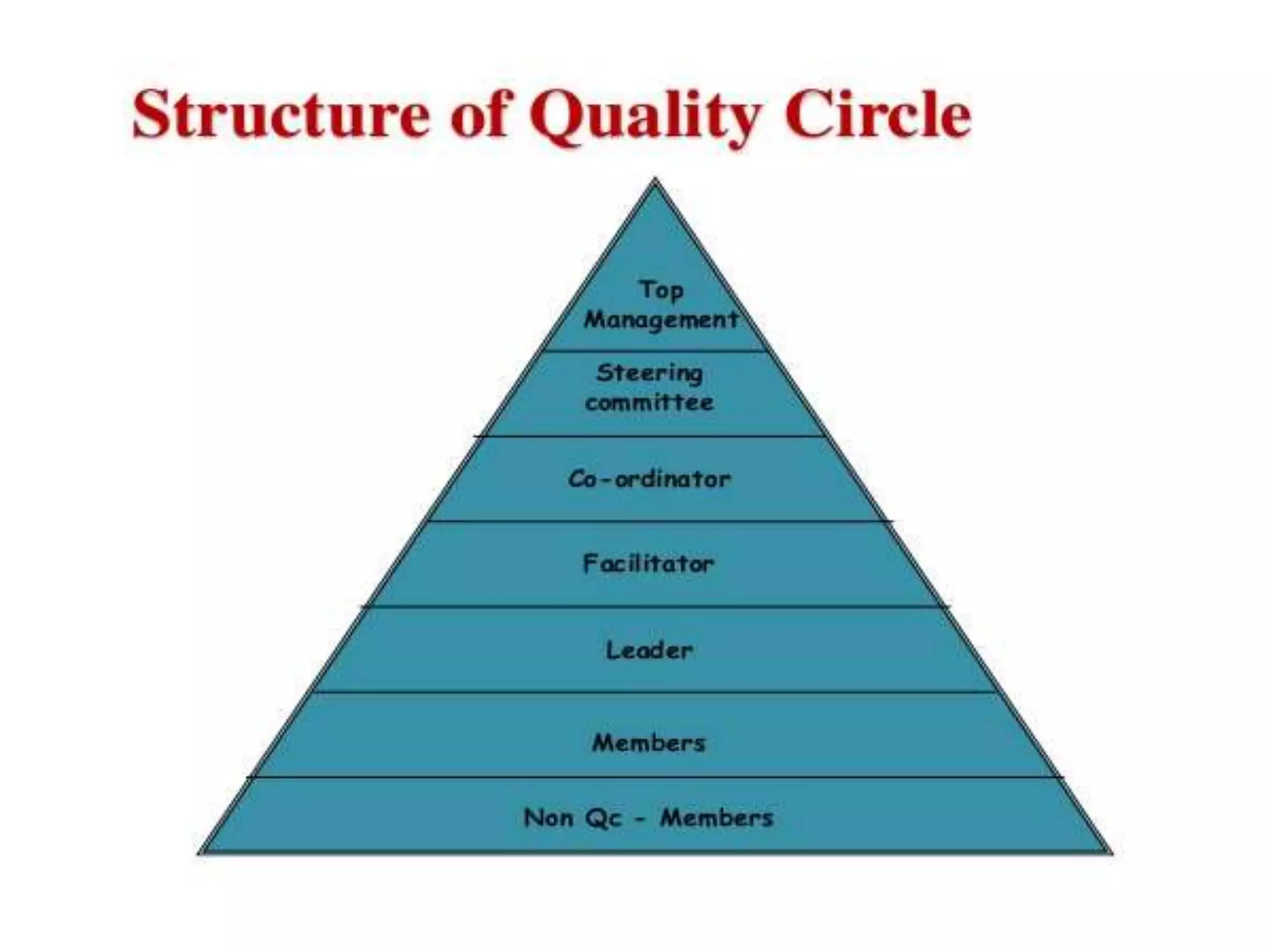

The document discusses quality circles, small groups of employees collaborating to identify and solve work-related problems, and highlights their importance in fostering quality awareness and organizational competitiveness. It details the origins, objectives, processes, and various techniques associated with quality circles, emphasizing worker participation and the need for training at all levels of management. Additionally, it mentions the introduction of quality circles in India and the vision and mission of the Quality Circle Forum of India.