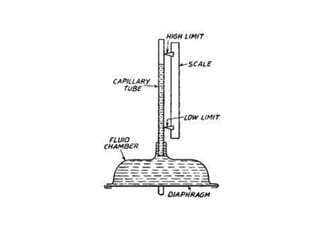

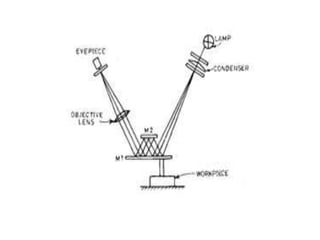

This document discusses different types of comparators used to measure dimensions. It describes mechanical, mechanical-optical, electrical, pneumatic, fluid displacement, projection, multi-check comparators, and automatic gauging machines. Comparators indicate differences between a workpiece and standard, rather than providing an actual measurement. They must provide accurate, fast readings and withstand temperature changes. Projection comparators enlarge shadows for complex part inspection. Multi-check comparators simultaneously measure multiple dimensions for efficiency. Automatic gauging machines continuously transport and inspect parts to identify defects.