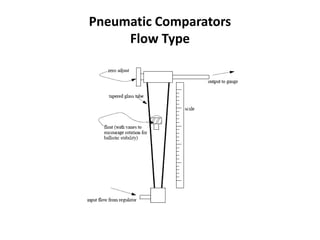

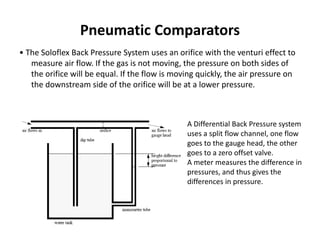

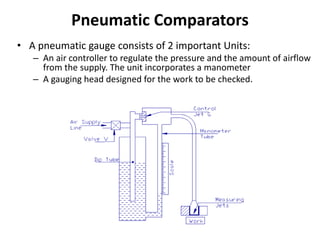

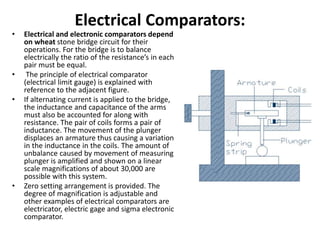

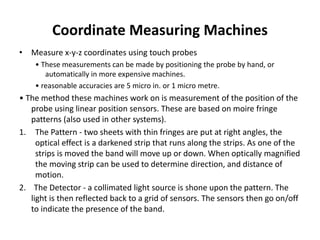

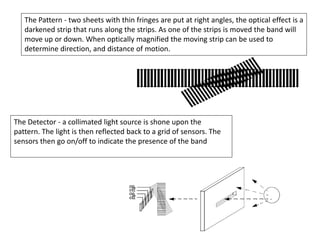

Comparators have very limited ranges of motion but high accuracy. They are often calibrated against standards like gauge blocks. There are several common principles used in comparator design, including mechanical, pneumatic, electrical, and optical systems. Comparators can differ in how they amplify and record measurements. Common types include mechanical, optical, electric/electronic, pneumatic, and coordinate measuring machines. Comparators have various uses in manufacturing including quality inspection, setting standards, and process control.