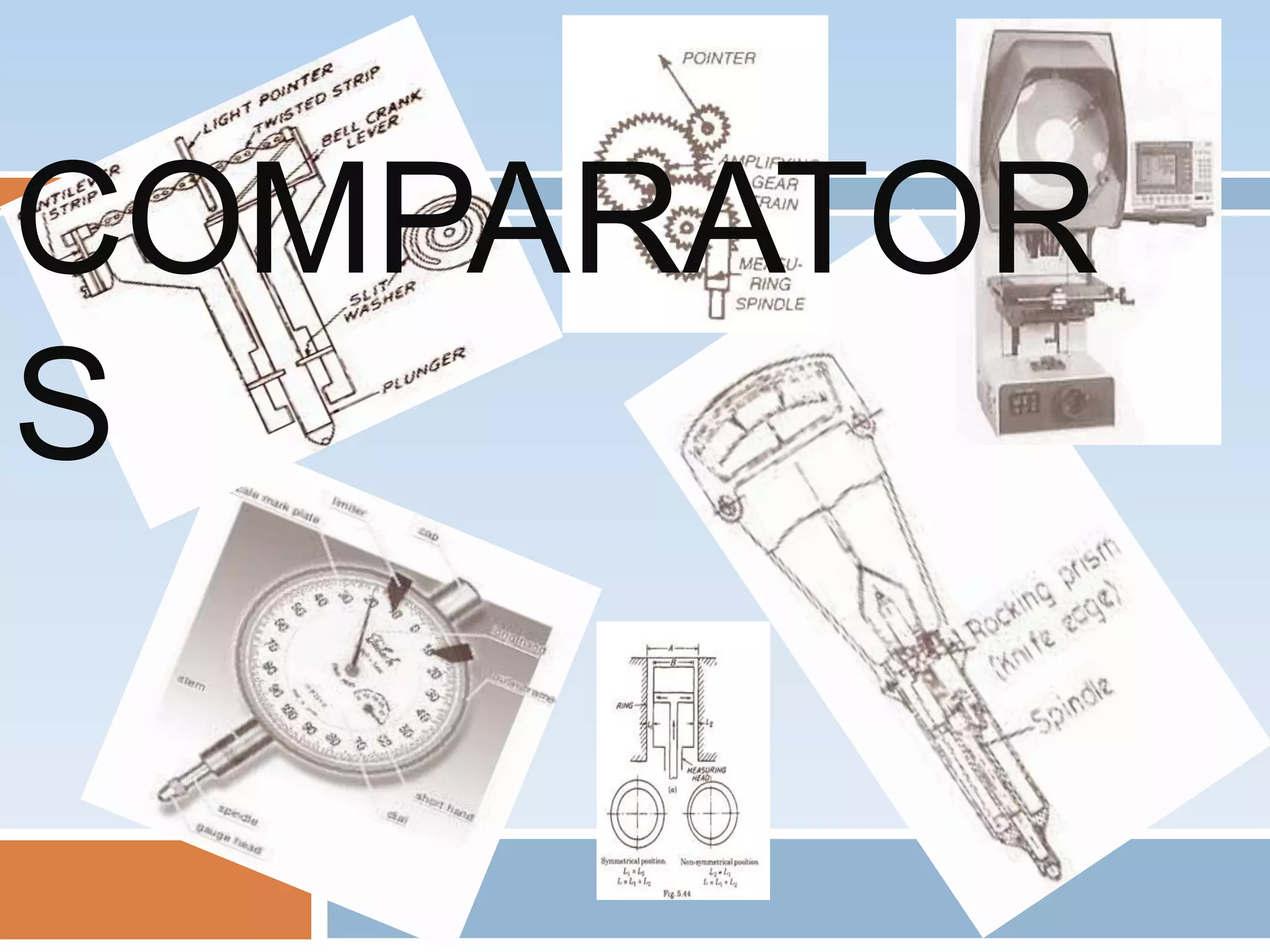

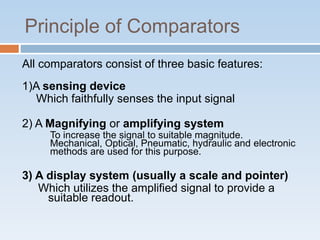

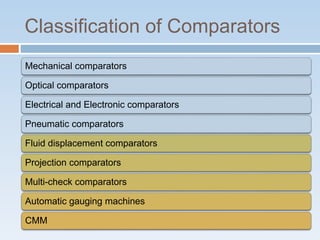

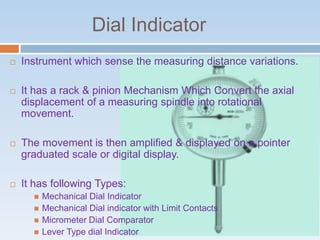

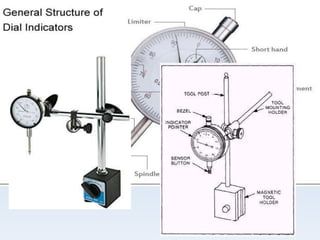

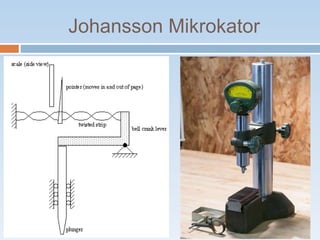

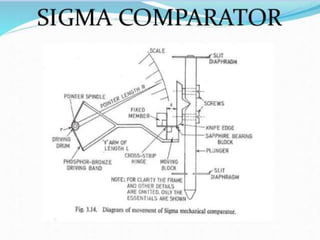

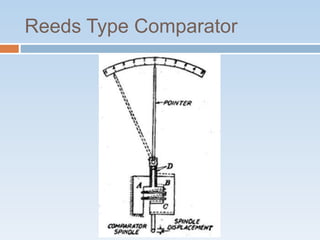

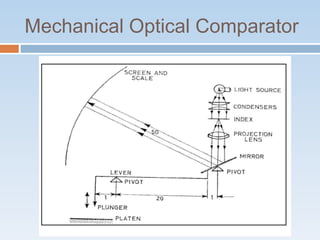

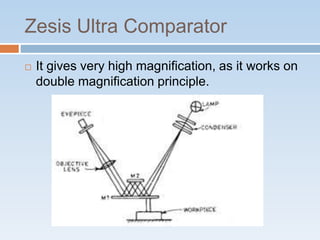

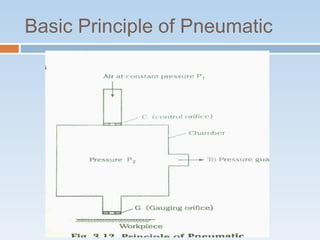

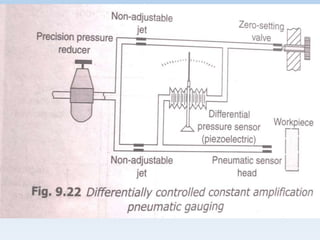

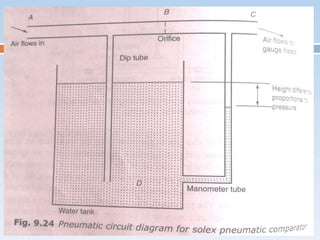

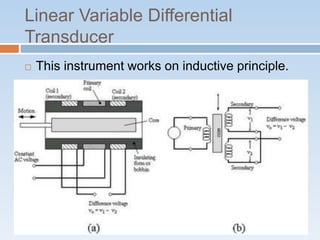

A comparator is a precision instrument used to compare the dimensions of a component to a standard. It indicates the differences in size but does not directly measure dimensions. Comparators can be mechanical, optical, pneumatic, electrical or electronic. Mechanical comparators use linkages and levers to magnify movements, while optical comparators use both mechanical and optical systems. Pneumatic comparators measure air pressure or flow differences. Electrical/electronic comparators convert displacements to electrical signals. Each type has advantages like accuracy, but may also require external power sources or have limited ranges.