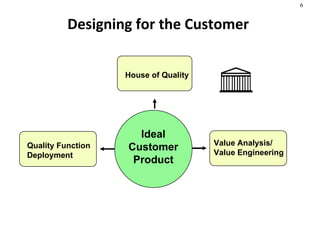

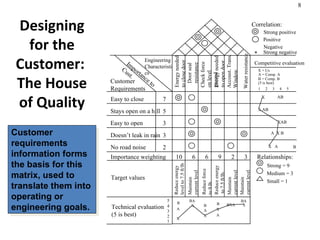

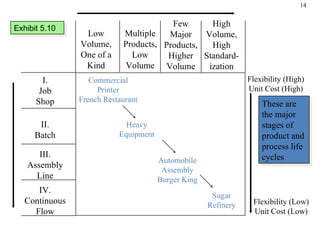

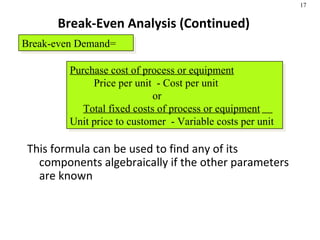

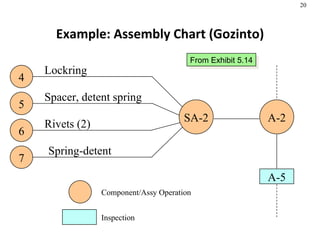

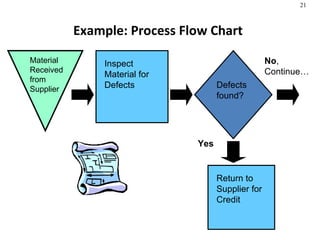

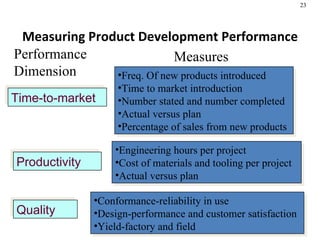

This chapter discusses product design and manufacturing process selection. It covers typical phases of product development like concept development and product engineering. It emphasizes concurrent engineering where functions work simultaneously to reduce time and costs. It also discusses designing for customers through techniques like quality function deployment and value analysis. The chapter then covers different types of manufacturing processes and considerations for process flow design and global product design.