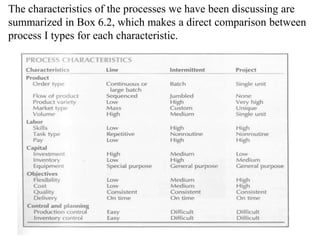

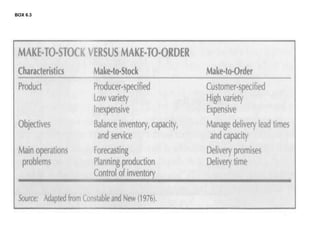

This document discusses different types of process flows and classifications for production processes. It describes three main types of process flows: line flow, intermittent/batch flow, and project flow. Line flow involves a linear sequence of standardized operations, like an assembly line. Intermittent flow involves production in batches using flexible, general-purpose equipment. Project flow is for unique, one-off products like works of art. The document also discusses how process selection decisions impact costs, quality, flexibility and other operational factors.