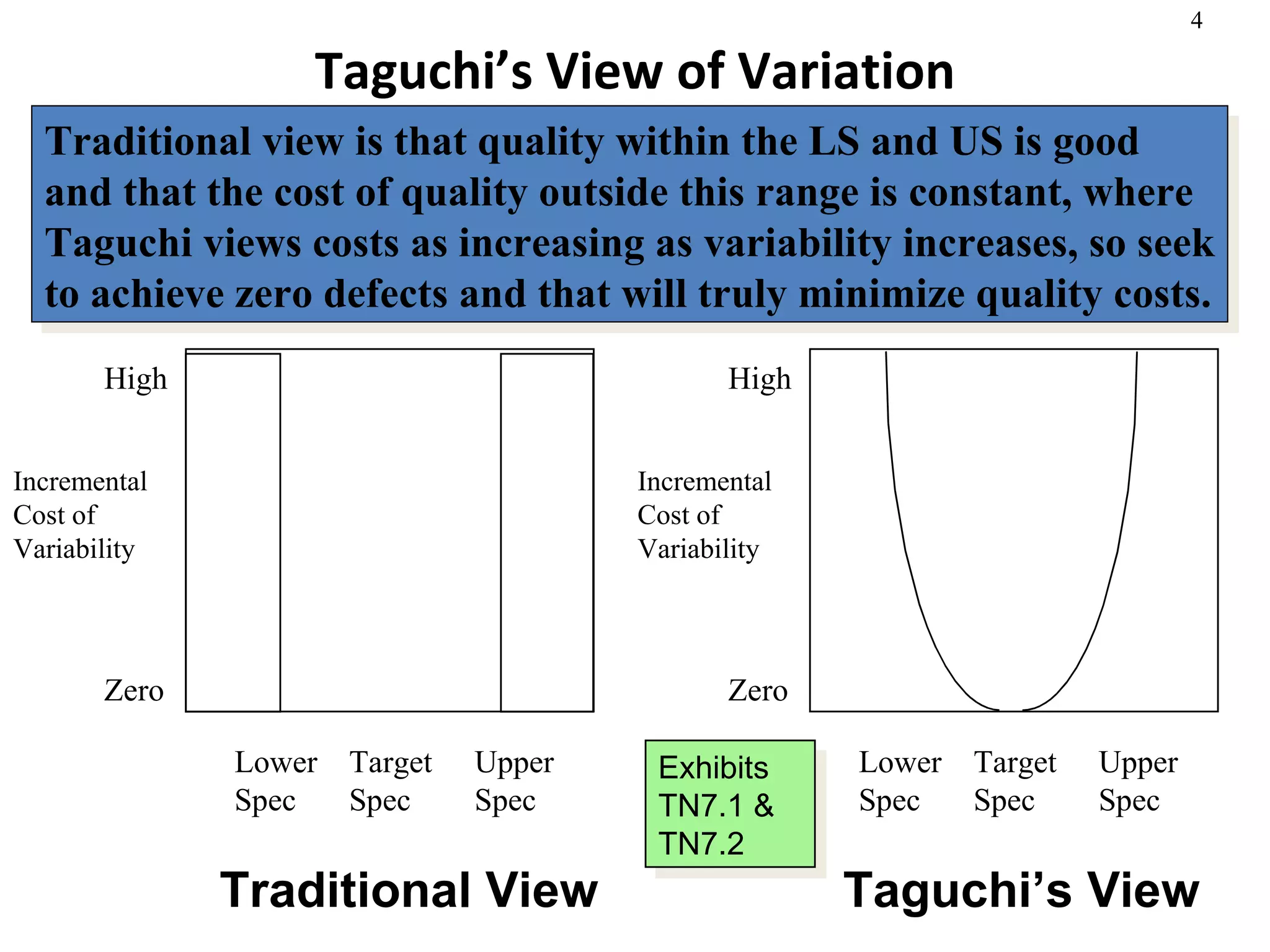

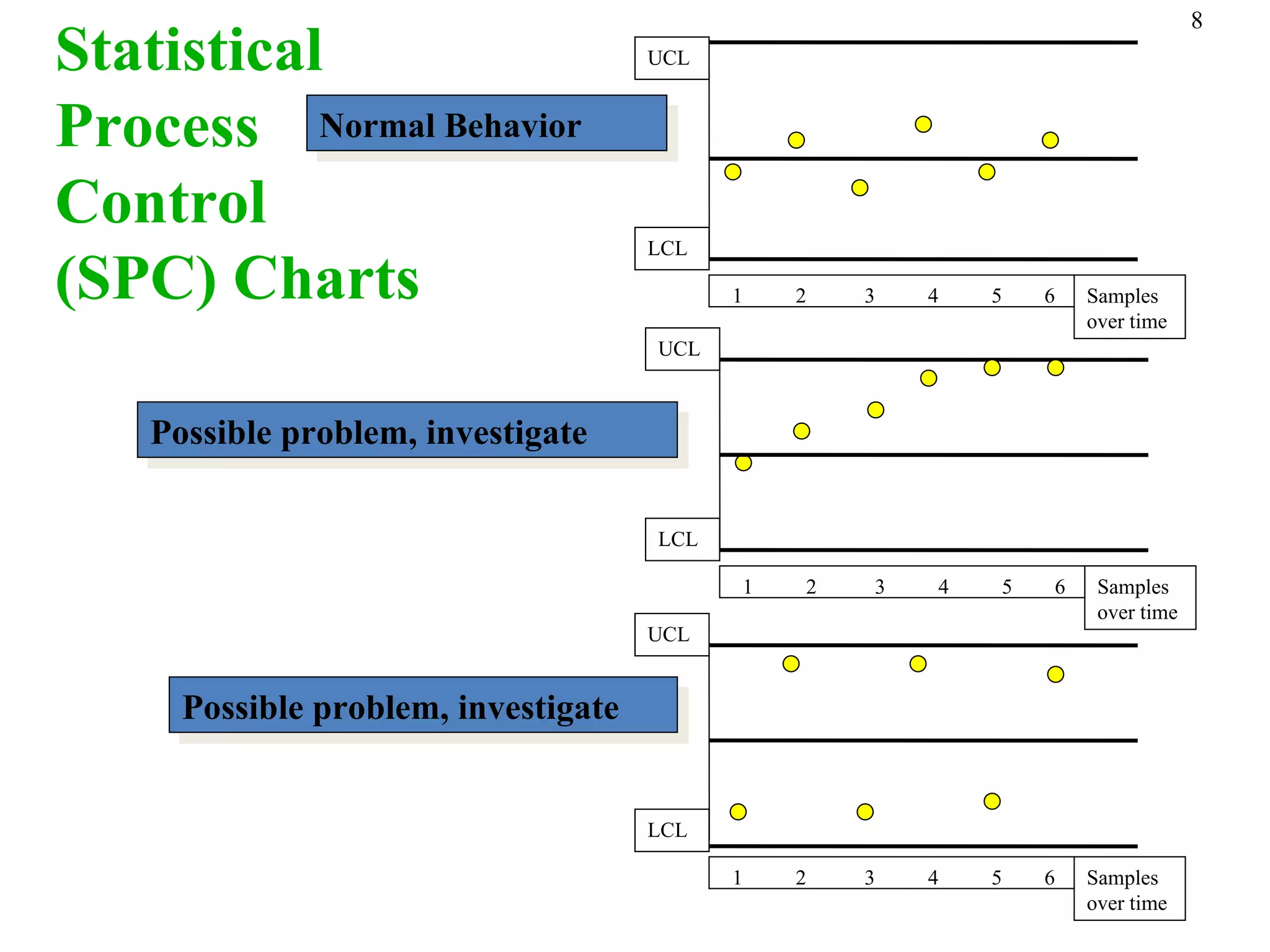

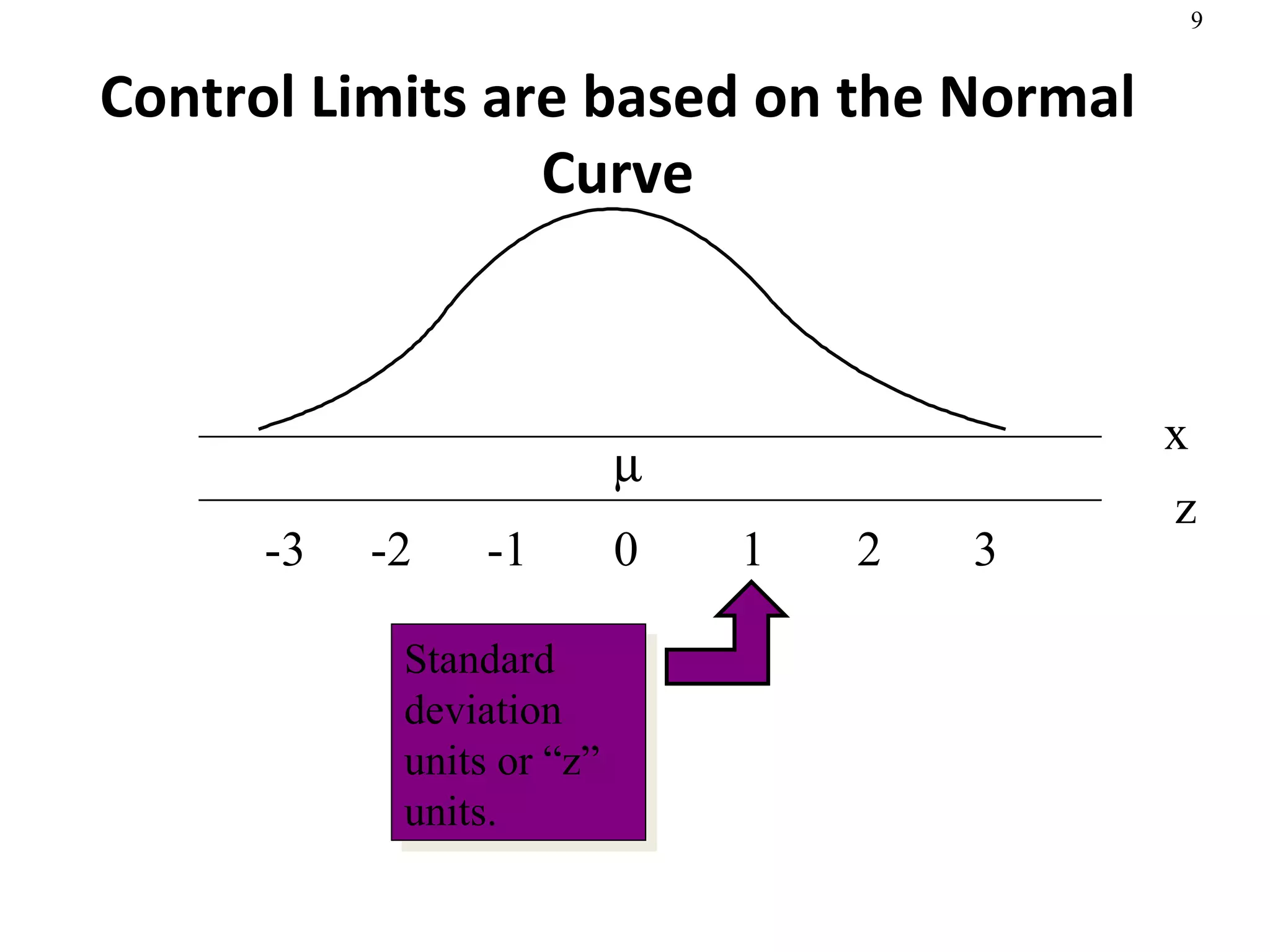

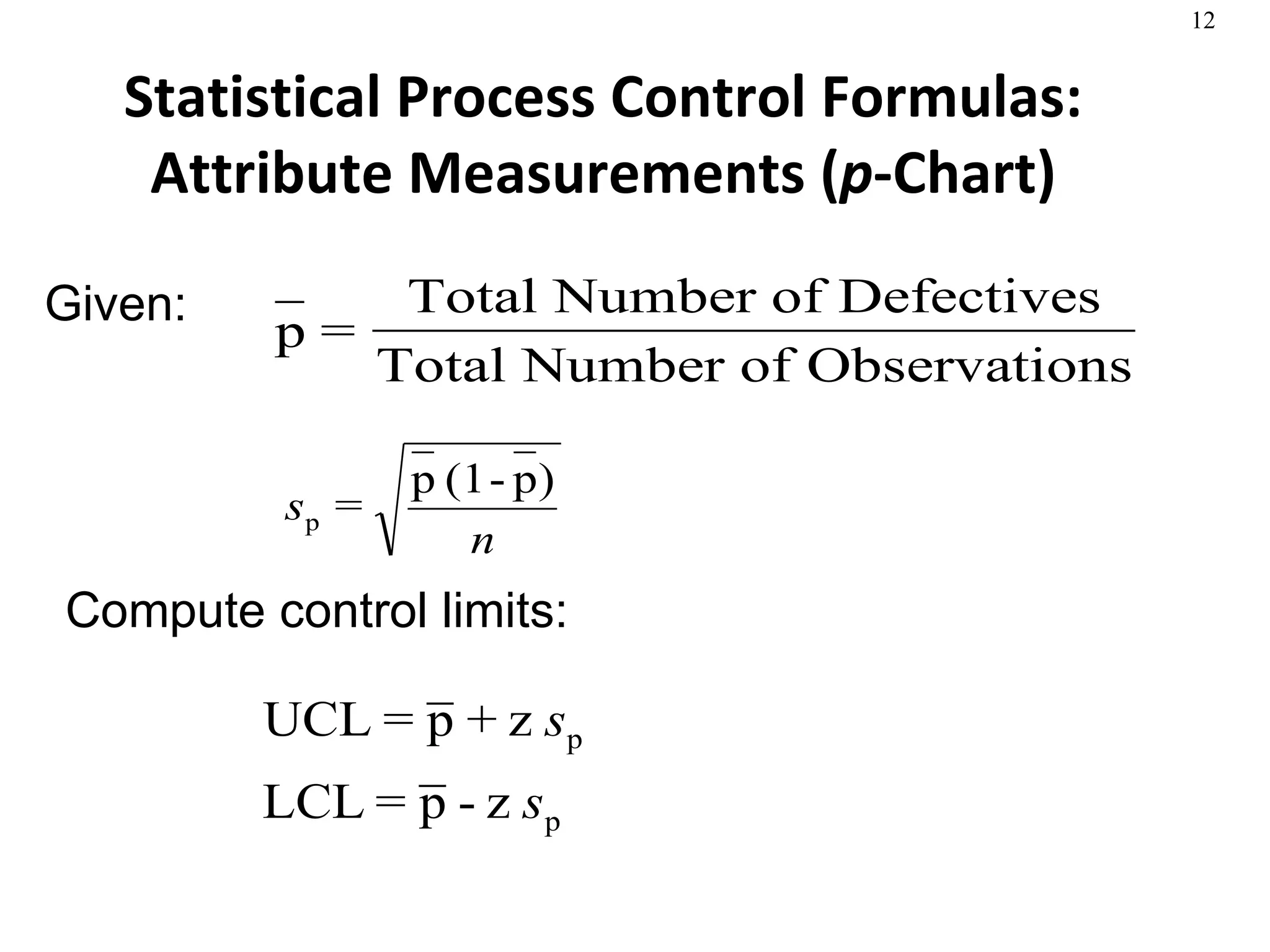

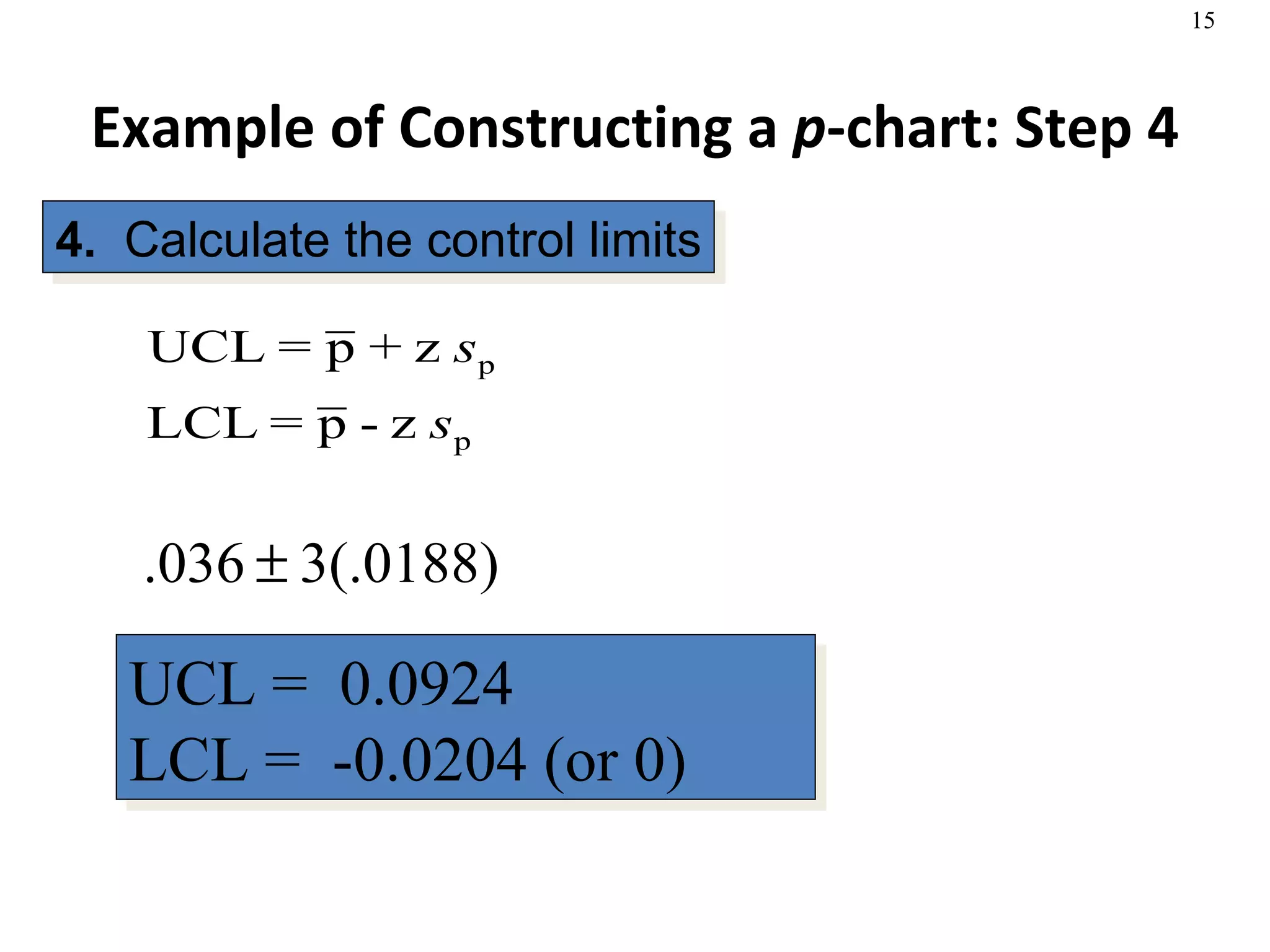

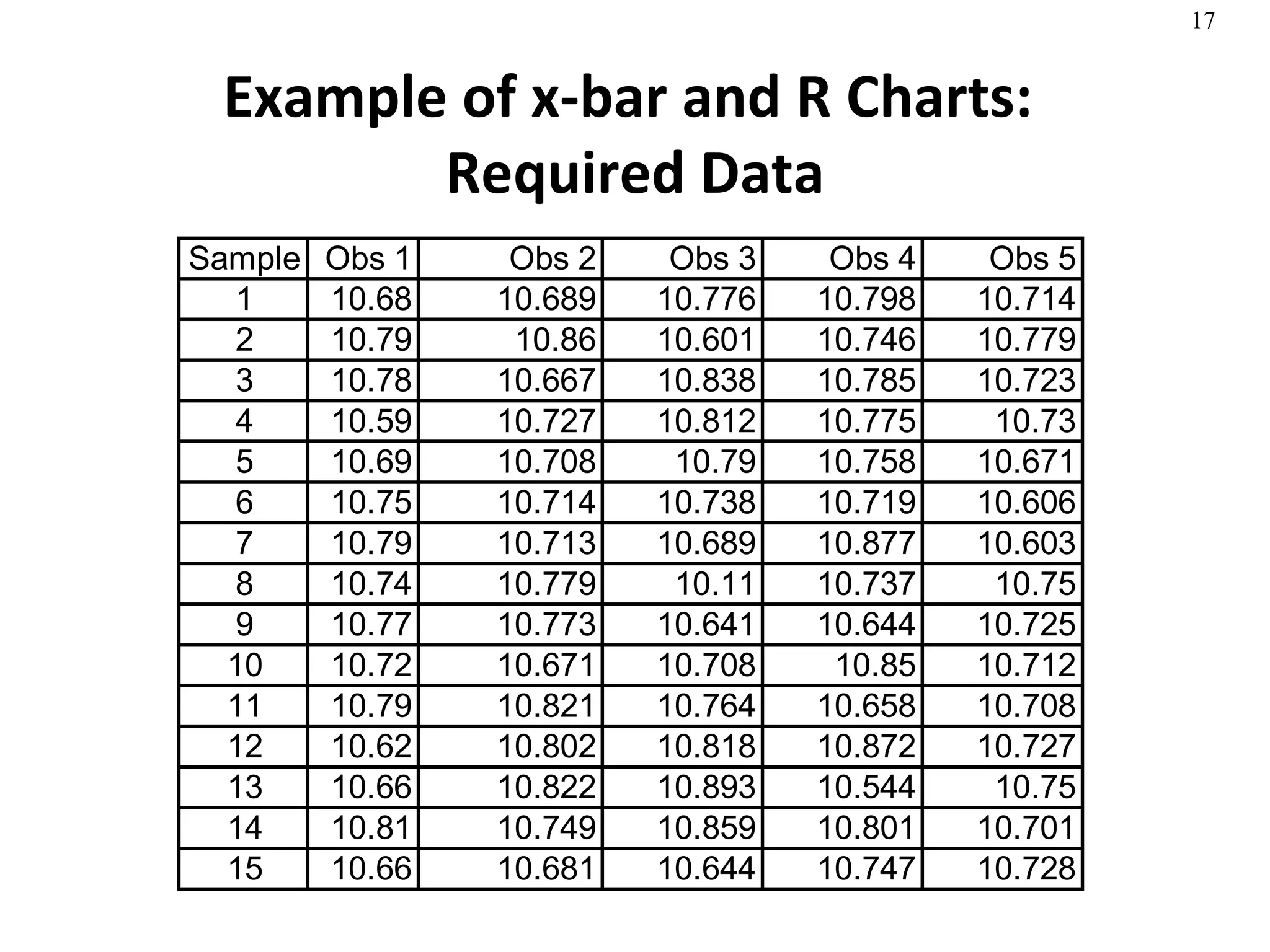

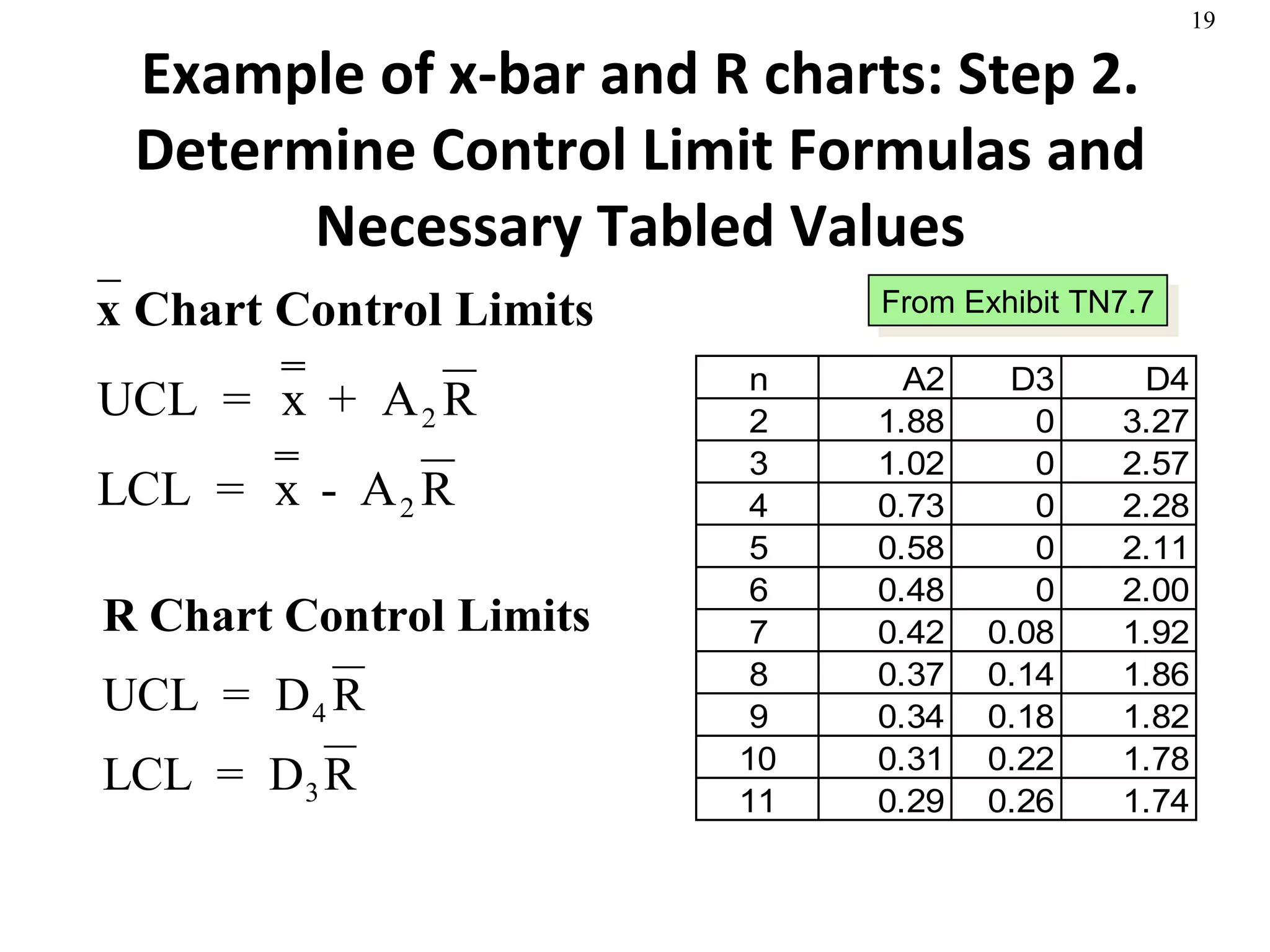

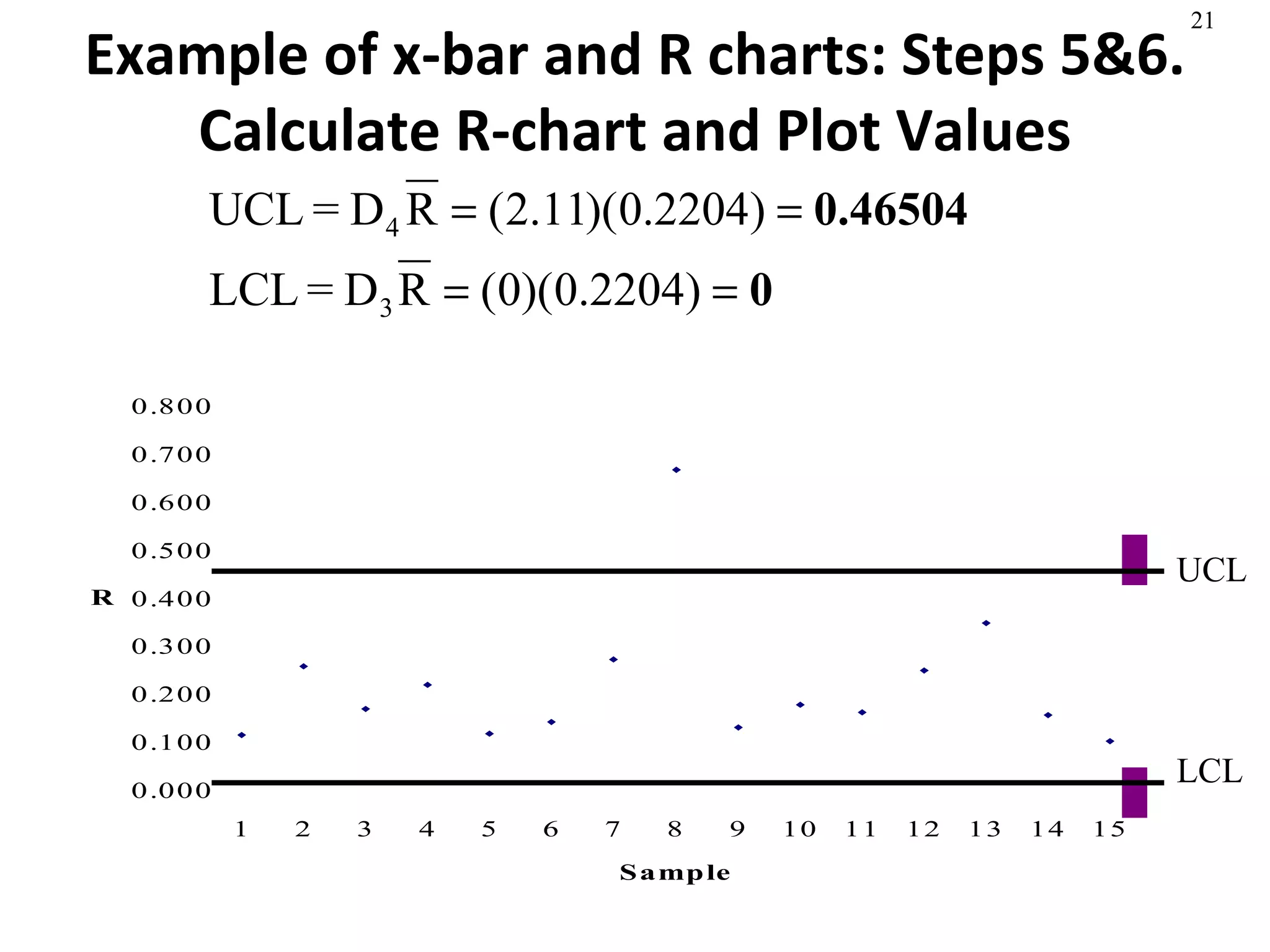

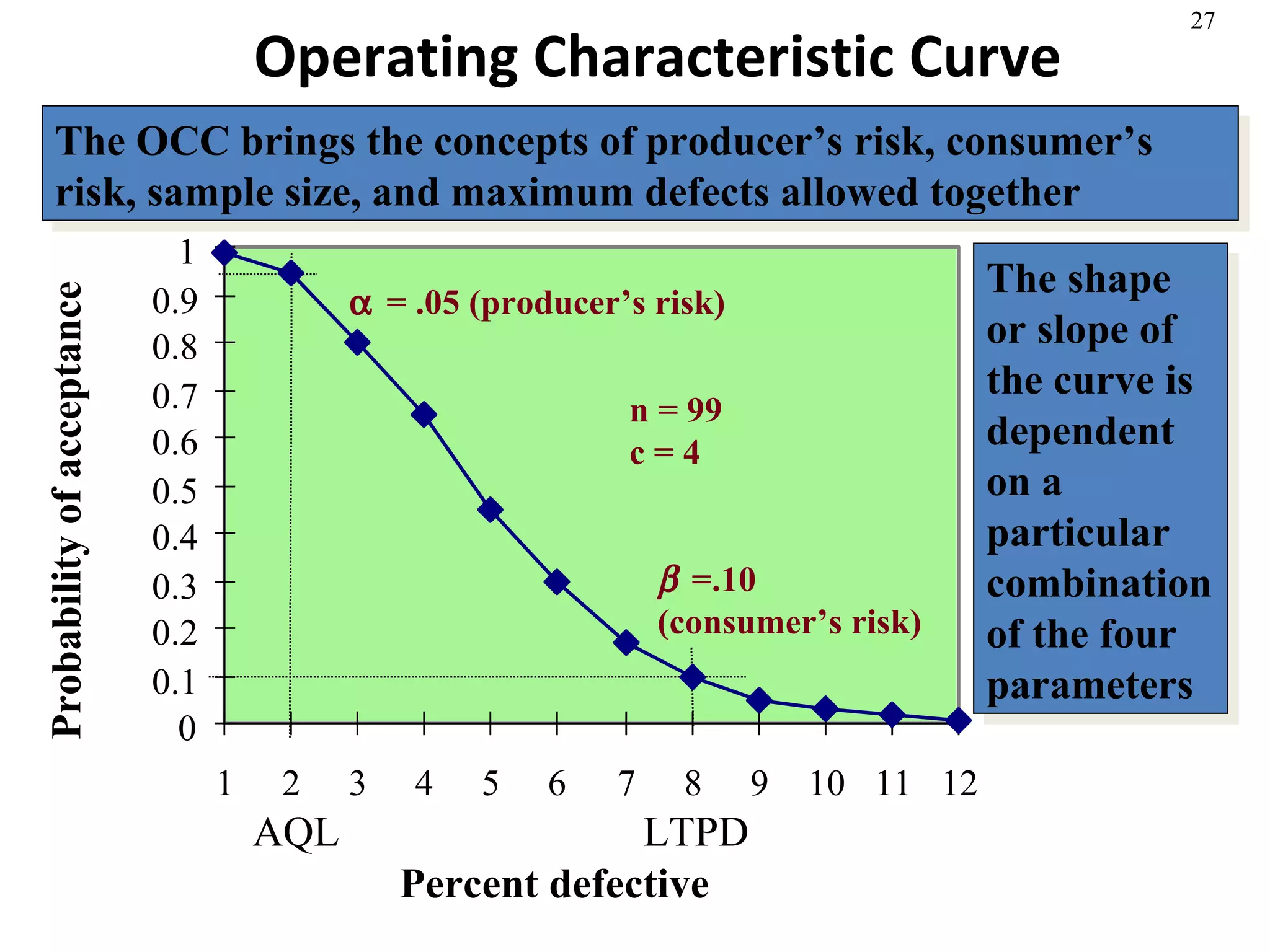

The document discusses process capability and statistical quality control. It provides information on different types of process variation and process capability indices. It also summarizes key concepts in statistical process control including control charts for attributes and variables as well as acceptance sampling plans. Examples are given for constructing control charts and solving acceptance sampling problems.