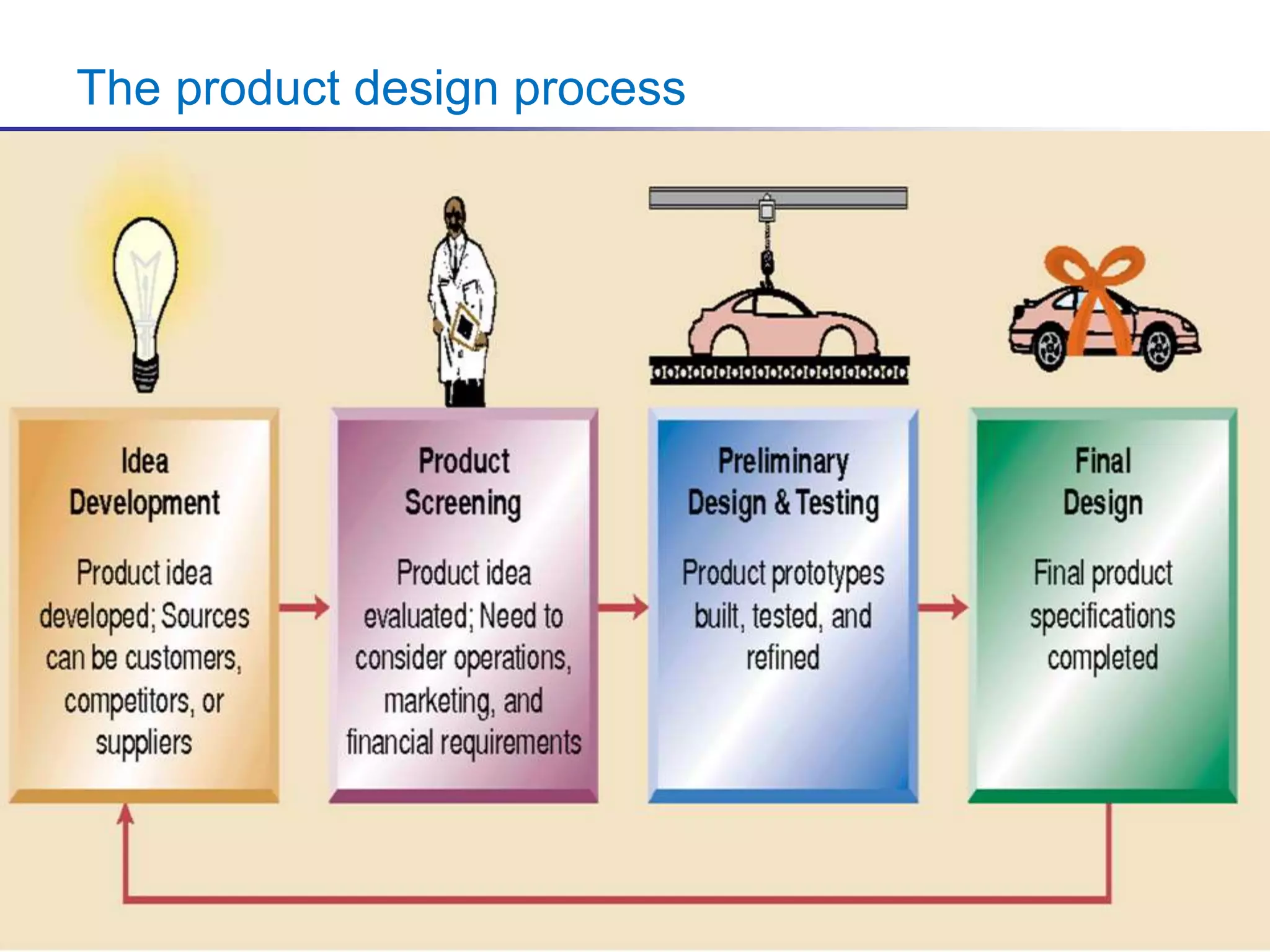

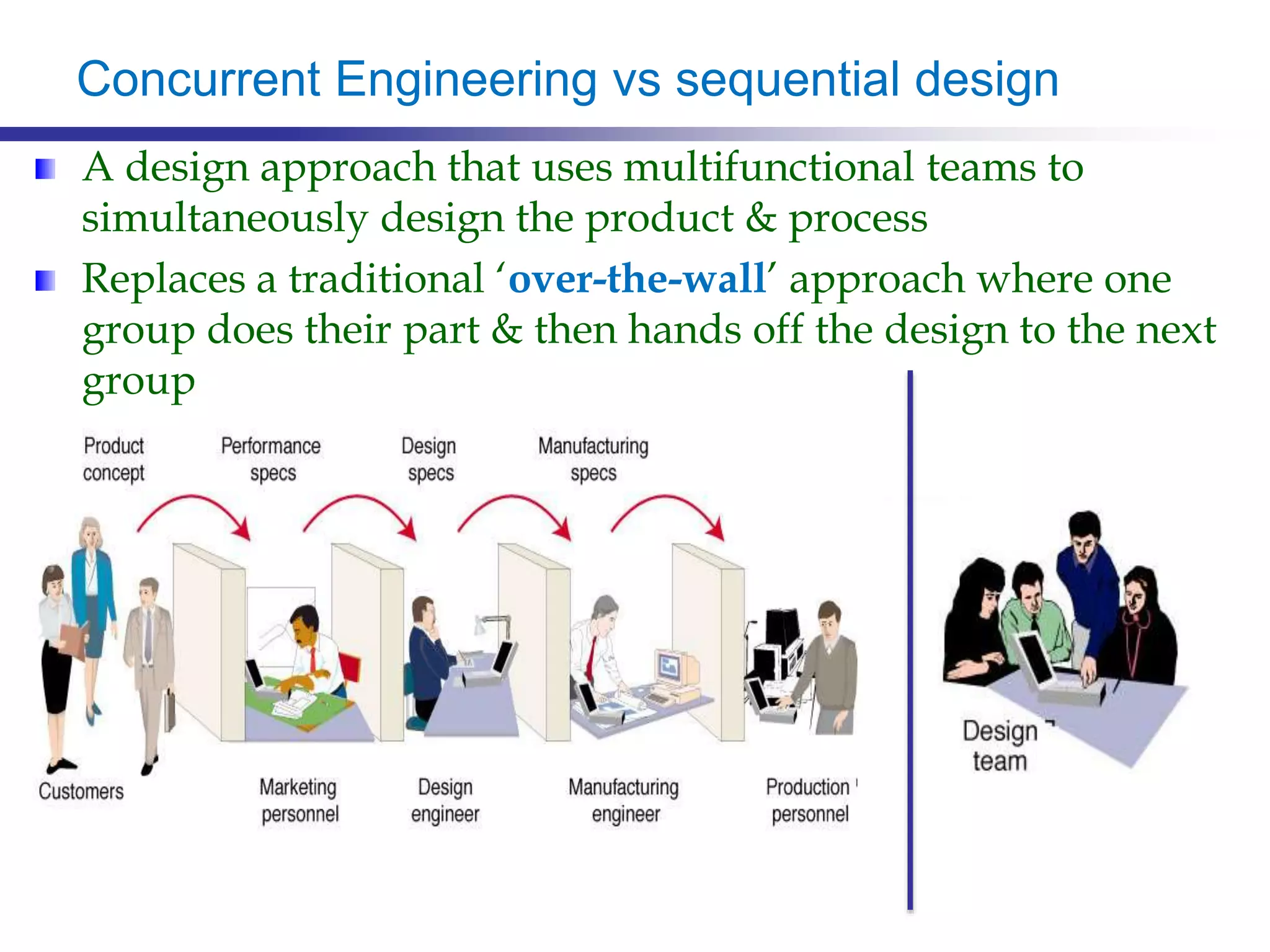

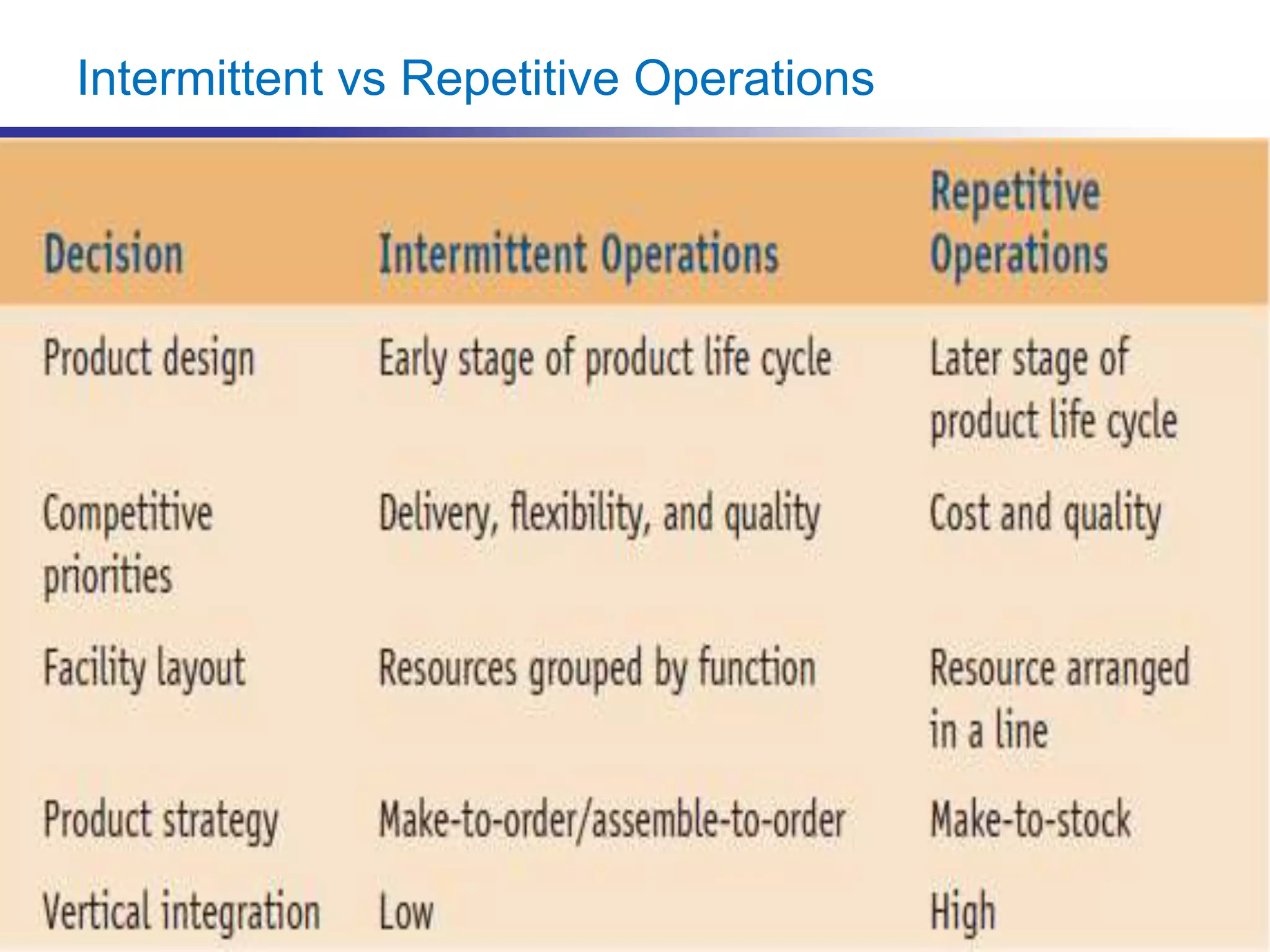

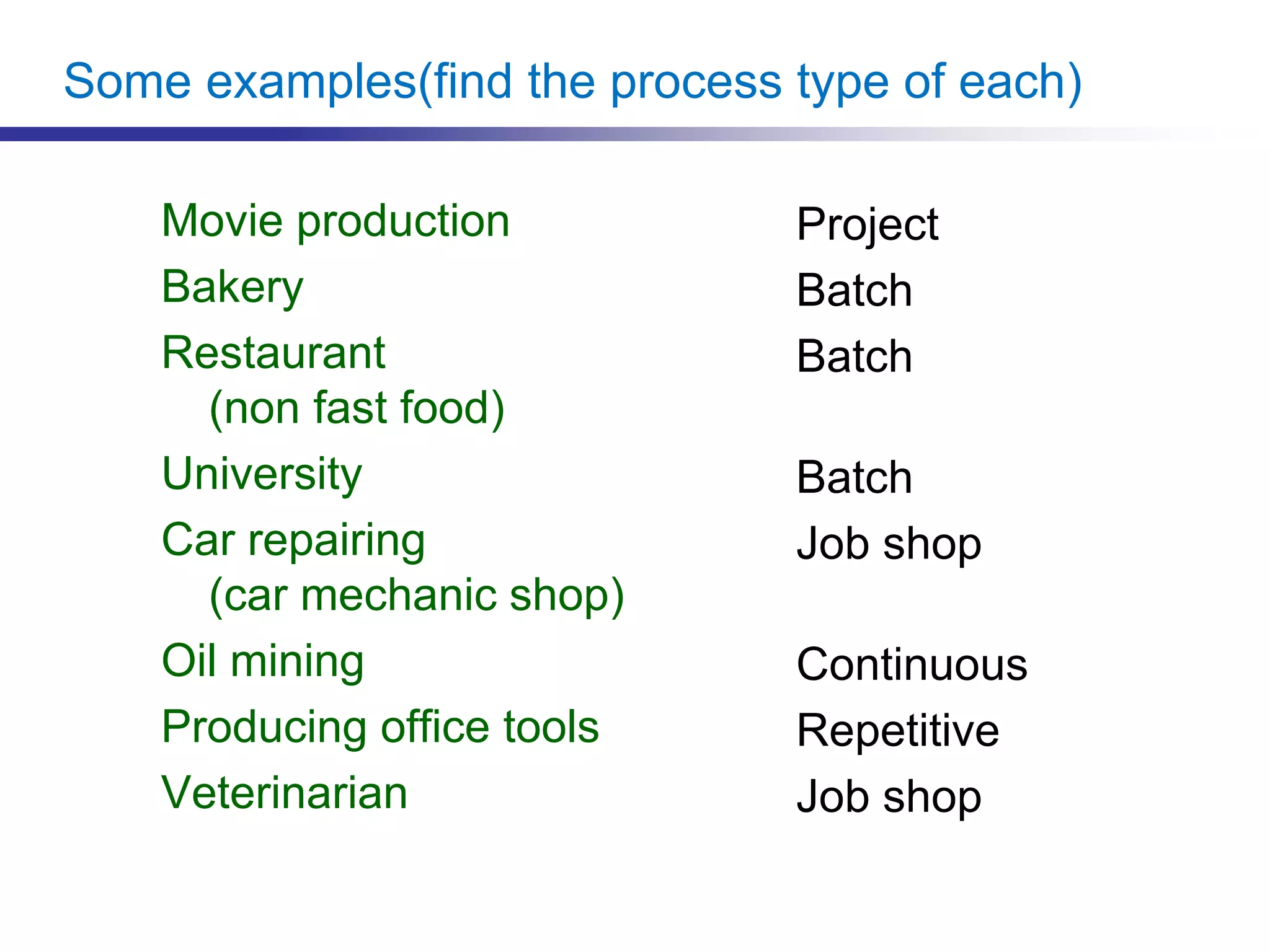

This document discusses product design and process selection. It begins by defining product design as determining the characteristics of a company's products, such as appearance, materials and performance standards. Reasons for redesign include market changes, costs and regulations. The main objectives of design are customer satisfaction and functional requirements. The product design process involves idea generation, screening, preliminary and final design. Issues in design addressed include concurrent engineering, standardization, mass customization, and environmentally friendly design. The document then defines process as activities that transform inputs into more valuable outputs. Process selection considers type of process, integration, flexibility and resources. Process types range from intermittent to continuous production.