This document provides an overview of the Design for Manufacture course, including its objectives, textbooks, and Chapter 1 content on introduction to DFM. The key points are:

- The course covers factors for designing parts for manufacturability, GD&T techniques, and design considerations for various machining operations.

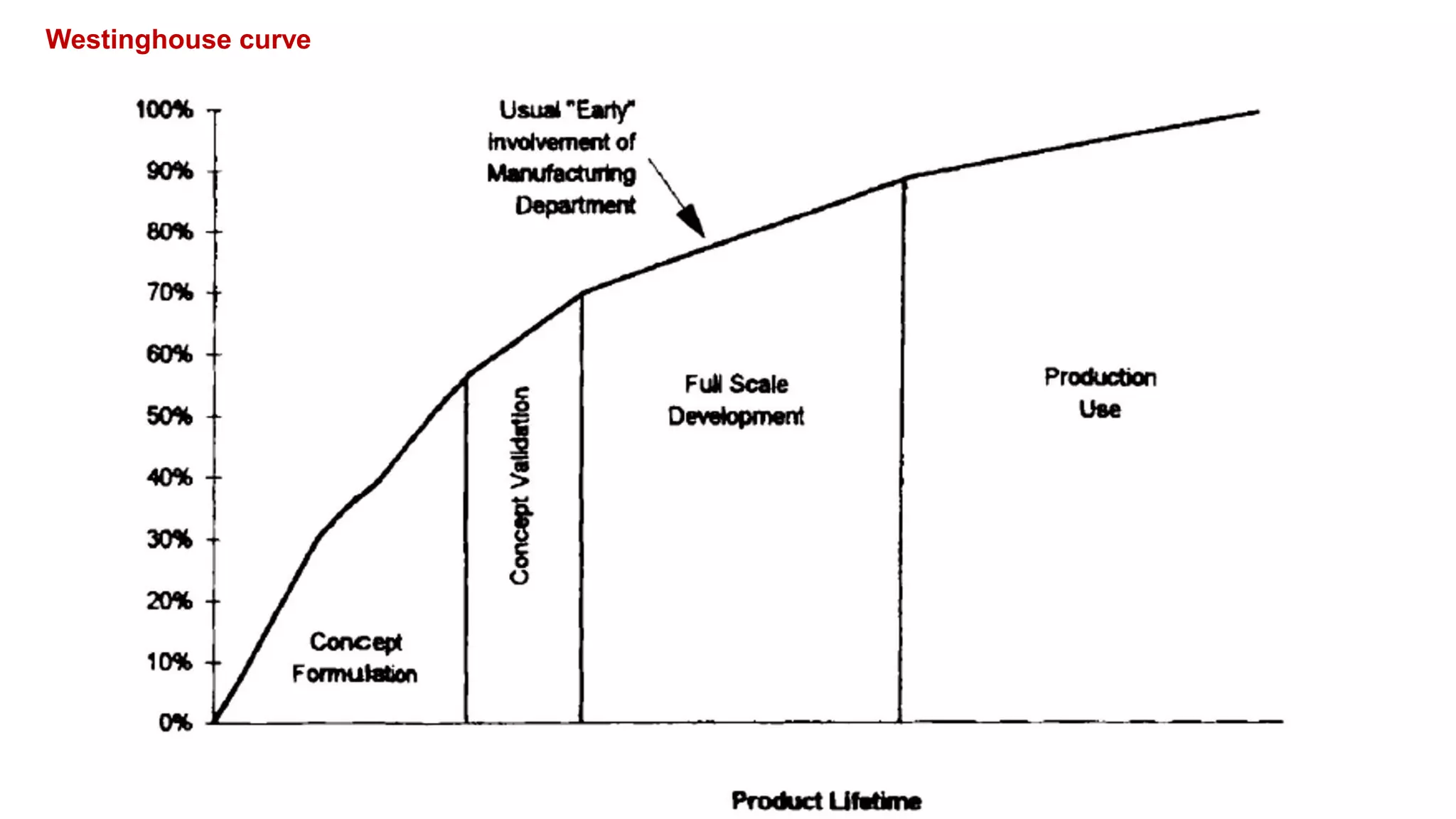

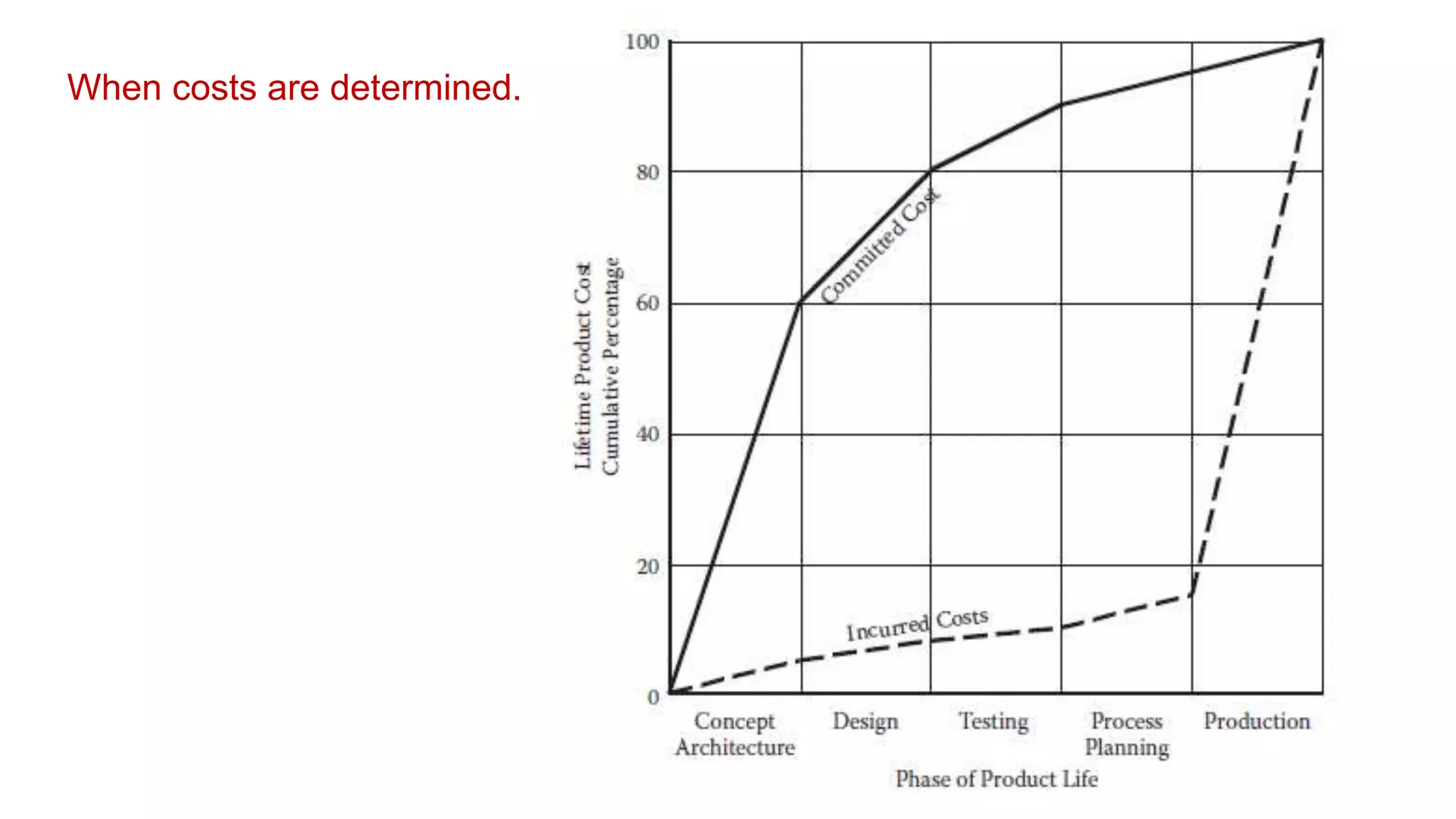

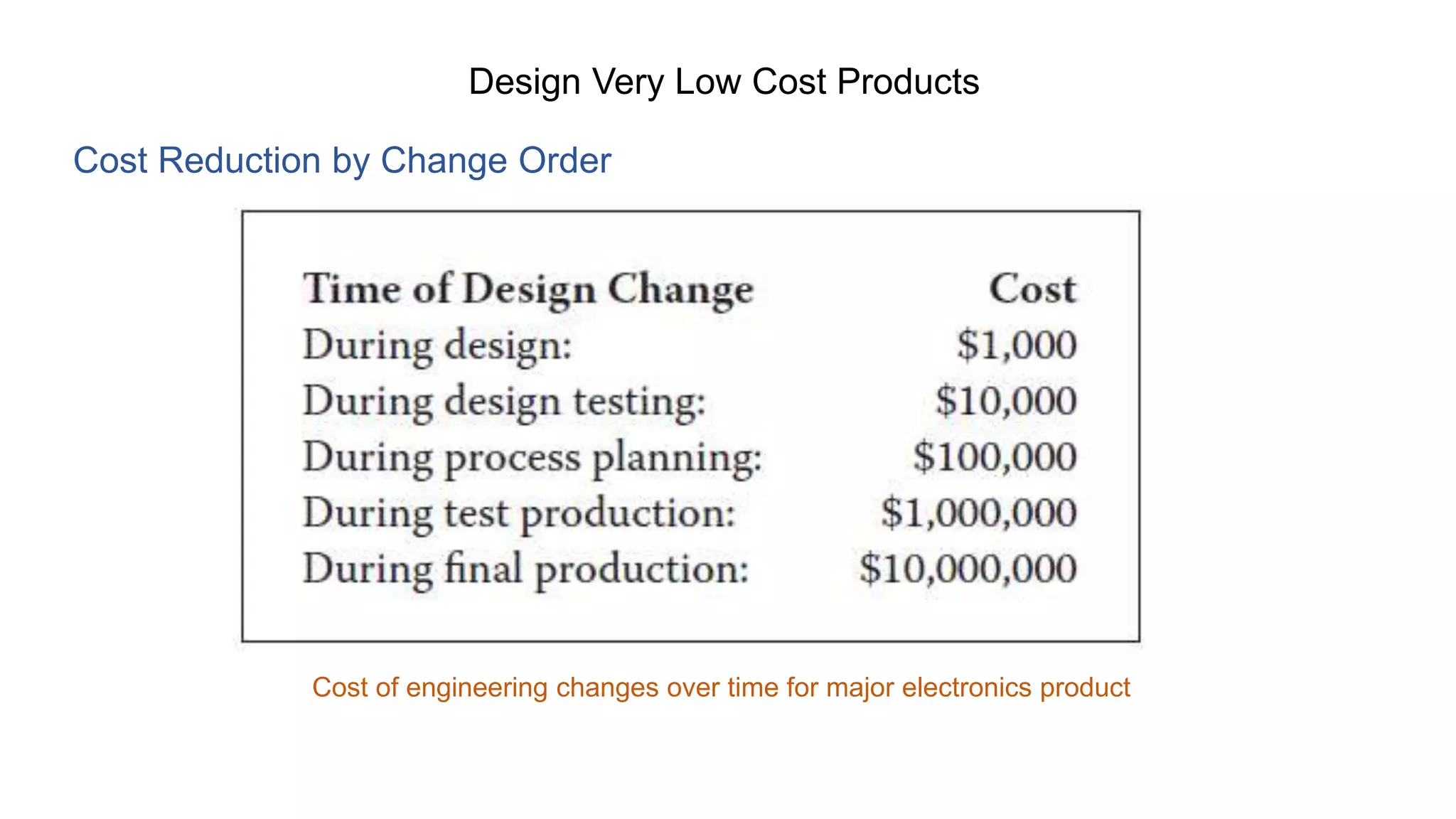

- Chapter 1 introduces DFM, the need for cost reduction, general design guidelines, advantages, and approaches like Taguchi's method and design for quality manufacturability.

- Major objectives of DFM are to estimate manufacturing costs, reduce component and assembly costs, and impact other factors through the design process.