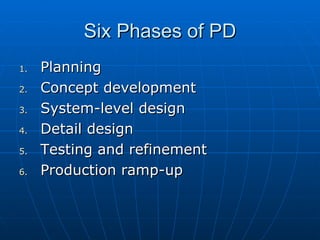

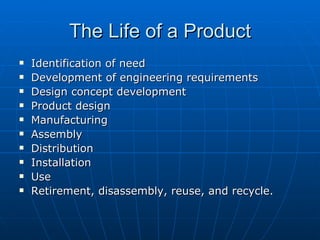

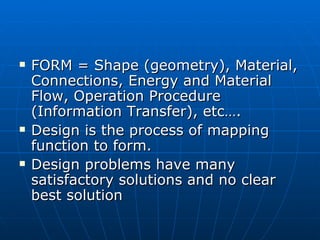

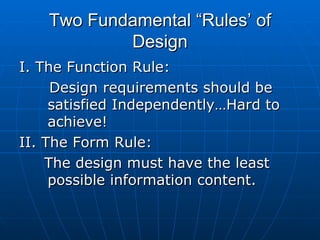

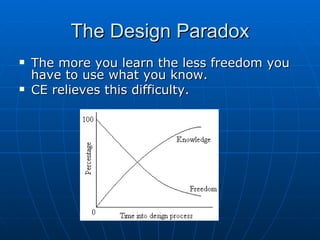

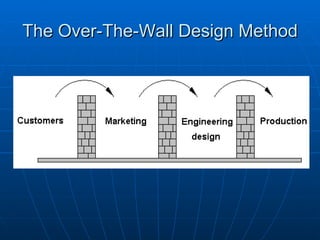

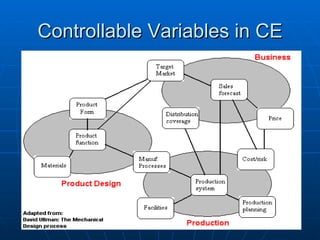

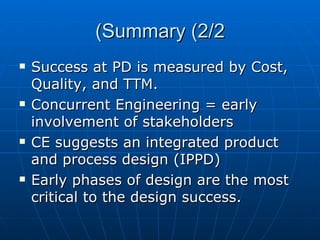

This document discusses key aspects of product design and development. It defines product, product development process, and design process. It outlines the six phases of product development and different types of products. The document also discusses product conceptual design, form and function, fundamental design rules, concurrent engineering approach, and composition of effective design teams.