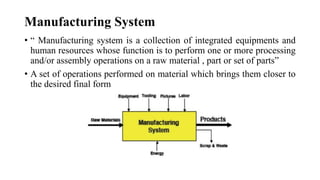

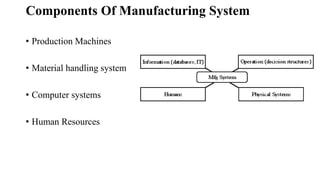

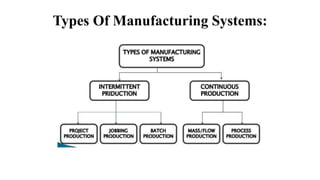

The document discusses manufacturing systems and lean manufacturing. It defines a manufacturing system as a collection of integrated equipment and human resources that perform processing and assembly operations on raw materials. It describes the typical input-transformation-output process. Examples of manufacturing systems include single station cells, machine clusters, and automated assembly lines. The key components of manufacturing systems are production machines, material handling systems, computer systems, and human resources. Lean manufacturing aims to eliminate waste from the manufacturing system, such as overproduction, waiting, inventory, transportation, and over-processing. It was pioneered by Toyota to increase efficiency and reduce costs.