Calculation Of Pump Head

- 2. What To Expect? Head Power Efficiency Applications Tidbits Videos

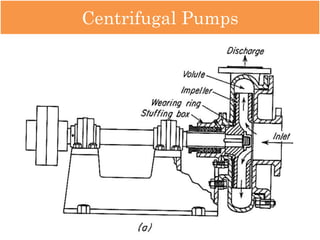

- 4. • Centrifugal Pump Working • Liquid enters through a suction connection concentric with the axis of a high speed rotary element called the impeller, which carries radial vanes integrally cast in it. Liquid flows outward, and leaves the impeller at a considerably greater with respect to the ground than at the entrance to the impeller. • Power is applied to the fluid by the impeller and is transmitted to the impeller by the torque of the drive shaft which usually is driven by a direct connected motor at constant revolutions commonly at 1750 r/min.

- 7. Centrifugal Pumps • Increase of mechanical energy, pressure by centrifugal force… • Most commonly used in the industry… • The impellers are curved backward…

- 12. 1 P S D Reservoir Shut Off Head 50 feet *In accordance with pump curves

- 13. In certain systems (admittedly unusual), the pump discharge line may have to run at a much higher elevation than the final discharge point. The fluid must first reach the higher elevation in the system. If the shut-off head is smaller than the static head corresponding to the high point, then flow will not be established in the system. During start-up and checkout of the pump, a quick way to determine if the pump has the potential capacity to deliver the head and flow required, is to measure the shut-off head. This value can be compared to the shut-off head predicted by the performance curve of the pump.

- 14. Total Head is proportional to the difference in pressure at the discharge vs. the suction of the pump. To obtain a higher head, the rotational speed or the impeller diameter can be increased.

- 15. • So to calculate your head you need the following... 1. Flow rate in GPM or m^3/hour... 2. Friction losses... We are going to be using the flowrate of 20 GPM with 50 feet of total NOT VERTICAL pipe. [PD-PS/ꝭ]= height(2-1) + Friction Losses(2-1) Head

- 16. • How To Choose A Pump • Usually we choose a pump on the basis of it’s head which is basically a generic term given to the total mechanical energy content of a fluid at a given point in a piping system. So once we have established the no. of feet and flow rate that we want we want we can go to the manufacturer. 1 Pump 2 S D Reservoir Tank Flow Rate 7GPM .5 inch 15 feet

- 18. • The table does not know how many feet of pipe you have so therefore it lists pressure loss for a 100 feet of pipe. 100 feet of pipe 48.8 feet of head loss We have 50 feet of pipe =24 feet

- 20. Height from point 1 to point 2, in our case it is 15ft… 1. You also need to account for the head you’re going to be losing because of the friction and you need to accommodate that, you can calculate the lost head due to friction by the use of tables, here you need to know the nominal diameter of your pipe and flow rate in gal/min…… Now all you have to do is add them up… • Also you ought to add a factor of 15-20 % for a commercial design to the values of the table... (Head) = 15ft + 24ft = 39ft

- 21. Characteristic Curves • The performance of a given pump is commonly illustrated by plots of actual head, power consumption, and efficiency versus volumetric flow rate. These plots are called characteristic curves. • ΔH is head capacity • P is power of the pump • Ƞ is the pump efficiency • NPSHR

- 23. 1. Technically if the head and the flow rate operating point for your system is located above on or below a performance curve then that pump will be sufficient to do it’s job (but do remember the economics!)... 2. A fixed speed circulator forces the system to work on it’s curve, a variable speed circulator adjusts its curve to meet the needs of the system.

- 24. Product Name Pump Curves This Means that at flow of 12 GPM in the product 007-(5) the pump will create a head of 6.4 ft. Or at 4 feet of head the pump will generate a flowrate of 17 GPM. 12 6.4 17 4

- 25. • Pump Head Compensation • From an industrial point of view pump head is very important, for every elbow/bend in pipe you have to add in a certain no. of head usually in feet in order to accommodate the losses… i.e. 1elbow=2feet then you’d have to add in 2 feet for every time that elbow appears in the piping… • So, you can see here the elbows are causing us 2 feet loss in head every time they appear so we have to add that in order to compensate the losses… We also have 3 ft. loss in head due to the vertical piping, we don’t count in horizontal piping… • So, Total Head = 9ft. + 12ft. + some excess feet to be safe... Pump Tank 22 2 22 2 3 3 3

- 26. • Cavitations And NPSH • If the suction pressure is only slightly greater than the vapor pressure some liquid may flash to vapor inside the pump a process called as cavitations which greatly reduces the pump capacity and causes severe erosion. If the suction pressure is actually less than the vapor pressure there will be vaporization in the suction line and no liquid can be drawn into the pump. • To avoid the cavitations the pressure at pump inlet must exceed the vapor pressure by a certain value called as the net positive suction head. The required value of NPSH is about 2 to 3 m (5 to 10 ft) for small centrifugal pumps but It increases to 15m (50 ft) are recommended for larger pumps.

- 28. Tid Bits

- 29. Rotary Pumps Multi Stage Centrifugal Pumps • High energy centrifugal can generate a head of 200 m only. • To increase the head (>200 m), multistage centrifugal pumps is used where multiple impeller is installed on a single shaft.

- 31. Pump Priming • What is it? • To remove the entrapped air inside the pump is called pump priming • When we do it? 1.First start up after a long time 2.First start up after maintenance 3.First start up for a new pump • How we do it? • If there is any air entrapped in the suction line, we need to replace this air with liquid. • Air can be displaced by pouring liquid from any tank into the suction line and submerge the pump impeller… Positive displacement pump can compress the gas to a required discharge pressure, that’s why they are known to self priming…

- 32. Pump Priming Priming of a pump is very essential step in start up of a centrifugal pump. Fact is that centrifugal pump are not capable of pumping air or vapors. Priming is the process in which the impeller of a centrifugal pump will get fully sub merged in liquid without any air trap inside. This is especially required when there is a first start up. But it is advisable to start the pump only after primping. Liquid and slurry pumps can lose prime and this will require the pump to be primed by adding liquid to the pump and inlet pipes to get the pump started. Loss of "prime" is usually due to ingestion of air into the pump. The clearances and displacement ratios in pumps used for liquids and other more viscous fluids cannot displace the air due to its lower density.

- 33. • Cavitations And NPSH • If the suction pressure is only slightly greater than the vapor pressure some liquid may flash to vapor inside the pump a process called as cavitations which greatly reduces the pump capacity and causes severe erosion. If the suction pressure is actually less than the vapor pressure there will be vaporization in the suction line and no liquid can be drawn into the pump. • To avoid the cavitations the pressure at pump inlet must exceed the vapor pressure by a certain value called as the net positive suction head. The required value of NPSH is about 2 to 3 m (5 to 10 ft) for small centrifugal pumps but It increases to 15m (50 ft) are recommended for larger pumps.

- 34. Pump Safety A note about centrifugal pump is that it doesn’t require a safety valve while a P.D pump must have a safety valve because at certain pressure C.F pump will stop producing any further pressure while the P.D pump will continue to increase pressure with every stroke until or unless the Safety valve blows or the discharge is opened… Turbulence Turbulence may be generated in other ways than by flowing fluid in a pipe… in general however it results from either of these scenarios, one is the flowing fluid gets In contact with a solid boundary called as the wall turbulence or two fluid layers moving with varying velocities contact called as the free turbulence… Free turbulence is especially important in mixing…