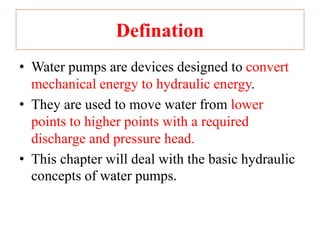

Three key points about reciprocating pumps from the document are:

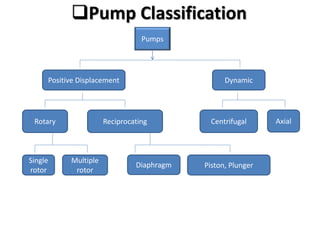

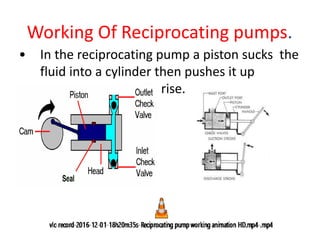

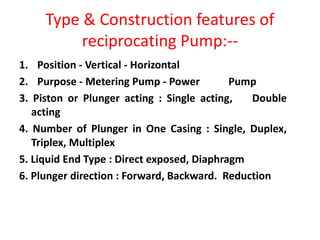

1) Reciprocating pumps use pistons or plungers that oscillate back and forth to move water from lower to higher points, converting mechanical energy to hydraulic energy. They are commonly used for applications requiring variable flow rates or high pressures.

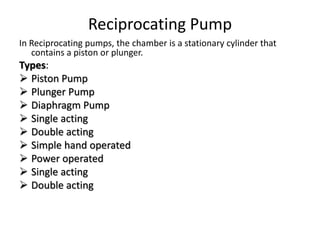

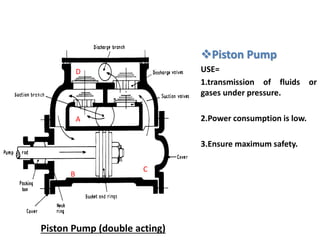

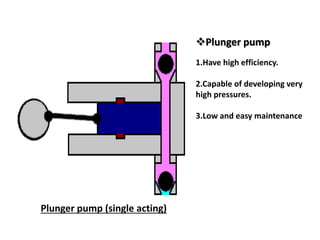

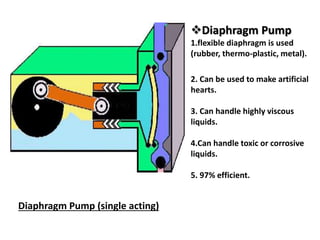

2) The main types are piston pumps, plunger pumps, and diaphragm pumps. Piston pumps are often used to transmit fluids under pressure, while plunger pumps are efficient and can develop very high pressures. Diaphragm pumps can handle viscous or toxic liquids.

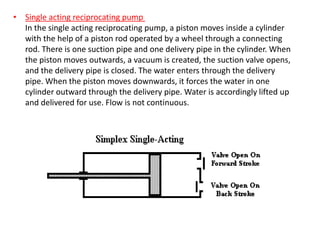

3) Reciprocating pumps can be single acting, where water is moved in one direction, or double