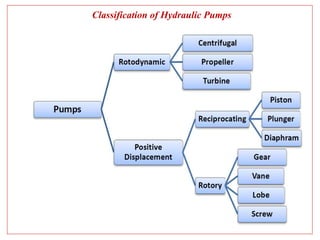

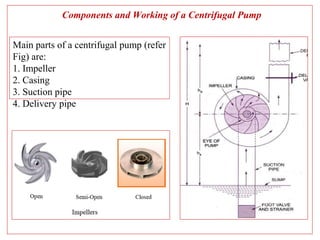

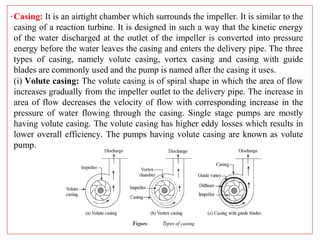

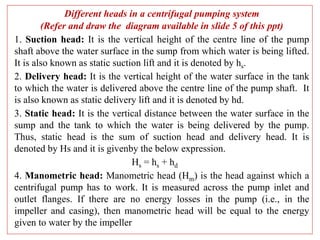

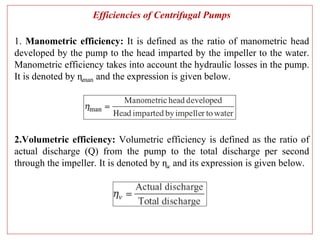

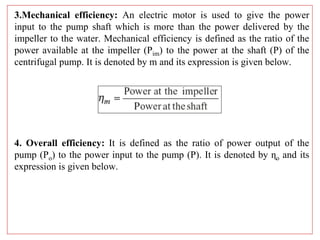

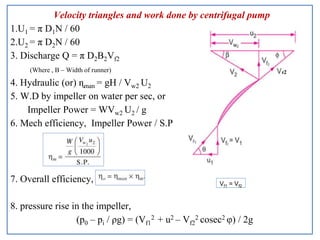

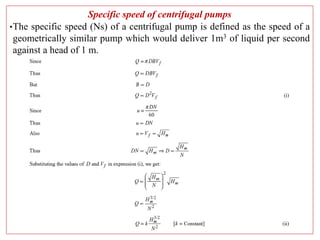

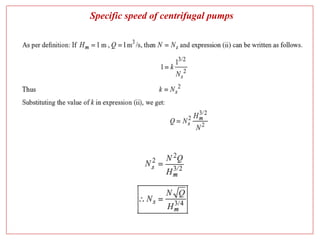

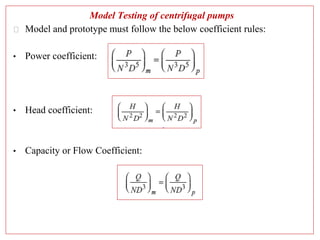

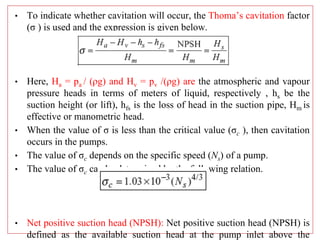

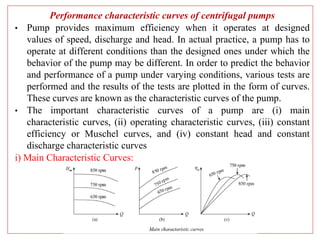

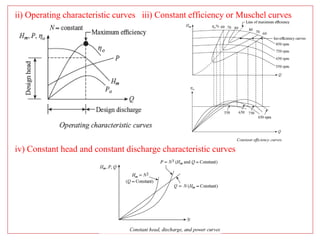

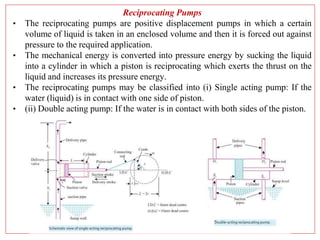

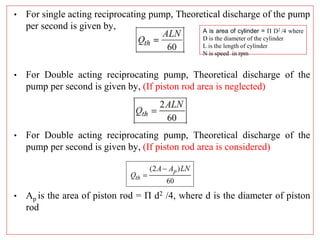

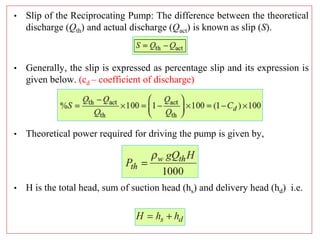

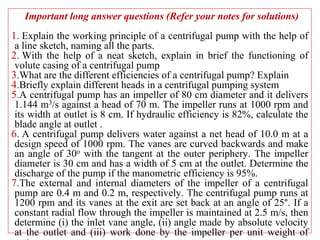

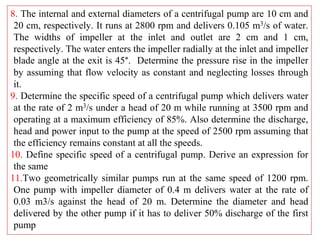

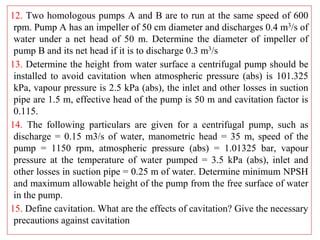

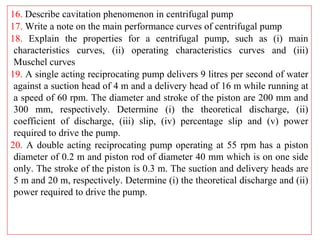

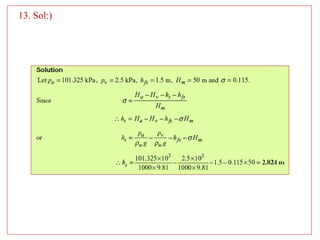

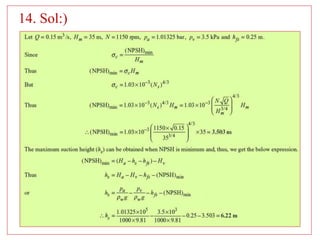

This document provides an overview of centrifugal pumps and reciprocating pumps. It defines key components of centrifugal pumps like impellers and casings, and describes how they work by imparting centrifugal force to increase fluid pressure. It also defines important pump parameters like head, efficiency, specific speed, and NPSH. Cavitation in pumps and methods to prevent it are explained. Performance curves for pumps are introduced. Finally, the working principle and equations for reciprocating pumps are outlined.