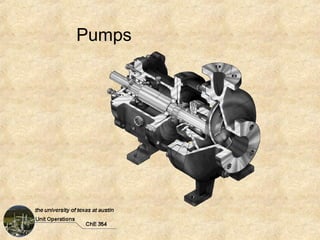

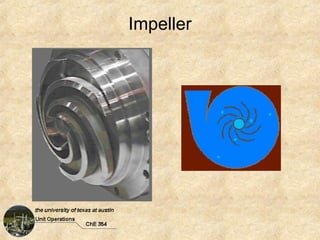

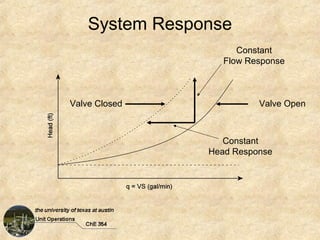

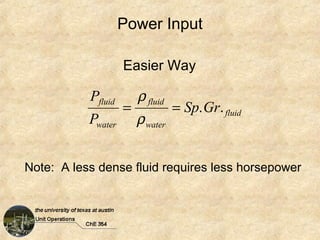

The document discusses various types of pumps used to move fluids, including centrifugal and positive displacement pumps. It describes how pump curves are used to determine the head, flow rate, efficiency and horsepower of centrifugal pumps. It also covers topics like net positive suction head (NPSH) and cavitation, as well as selecting an appropriate pump and pipe size for a given system.

![Optimum Pipe Size

For turbulent flow of liquids in steel pipes larger than 1 in.

Vopt [=] ft s

0 .1

12 m

Vopt = 0.36 m[=] lbm s

ρ ρ[=] lbm ft 3](https://image.slidesharecdn.com/che354pumps-130131035407-phpapp01/85/Ch-e354-pumps-32-320.jpg)