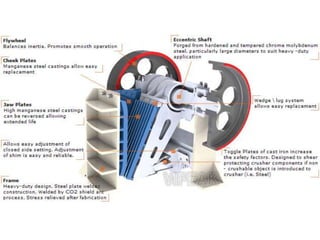

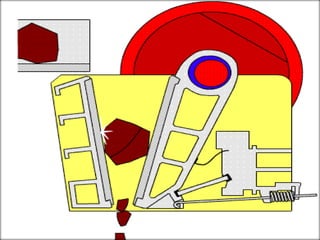

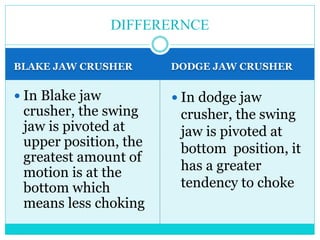

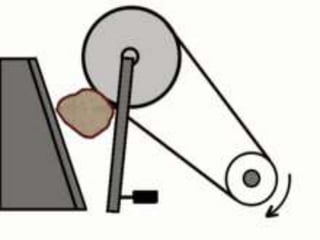

A jaw crusher uses compressive force for breaking rocks into smaller pieces by placing the rock between two surfaces, one of which moves back and forth relative to the other to crush the rock. Jaw crushers produce coarse particle size ranges from 150-250mm and can be either single toggle or double toggle designs. The crusher described in the document is a single toggle jaw crusher that uses an eccentric motion to crush rocks in a crushing chamber between the fixed jaw and swing jaw plate.