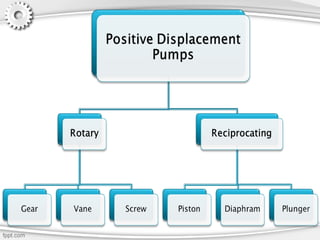

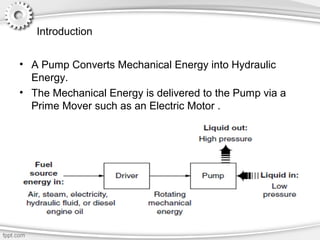

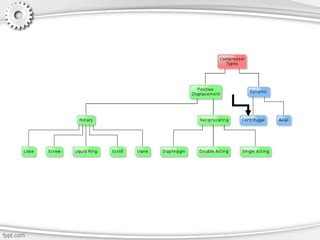

This document provides an overview of different types of mechanical pumps, including:

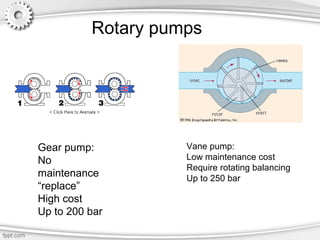

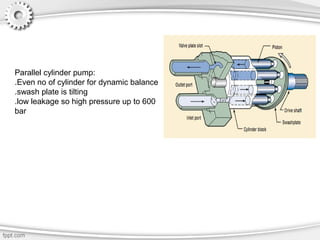

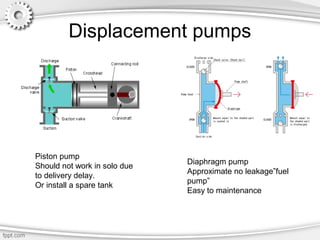

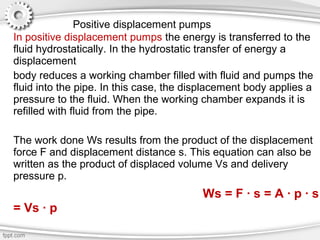

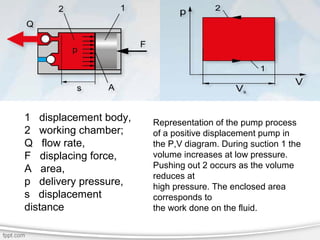

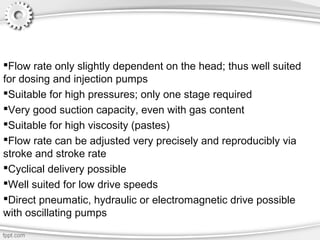

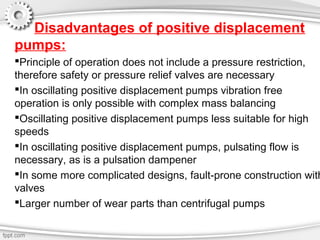

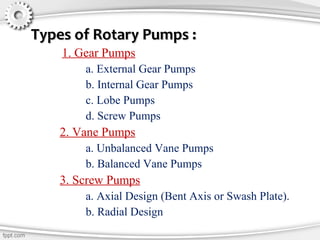

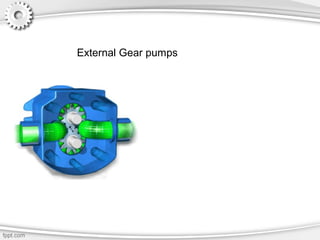

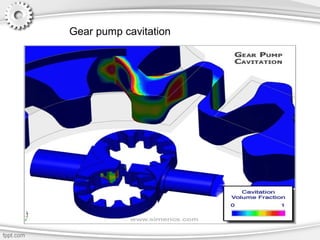

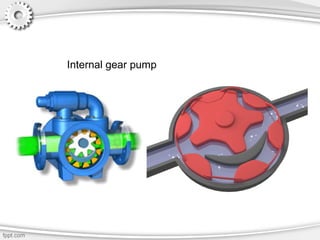

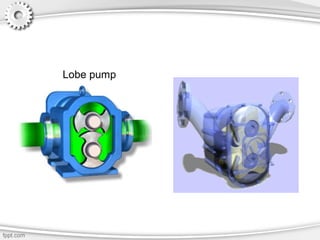

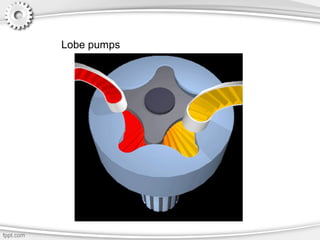

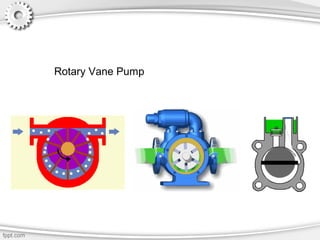

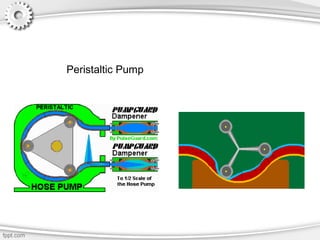

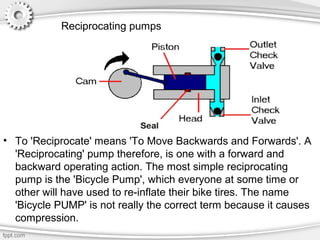

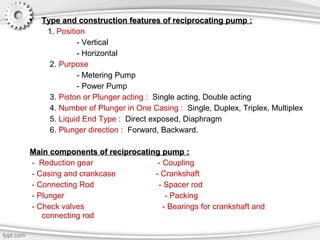

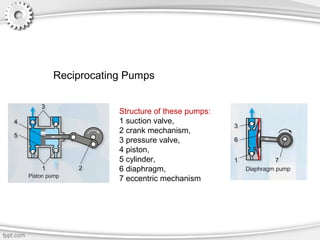

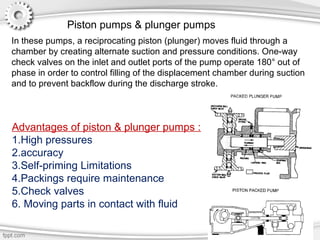

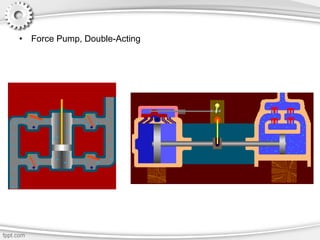

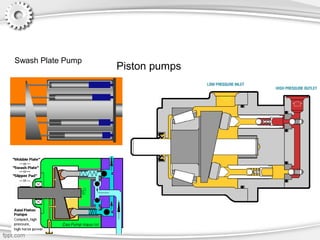

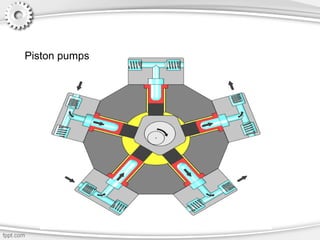

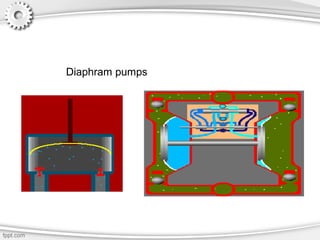

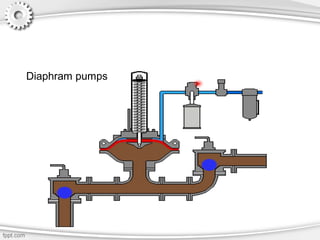

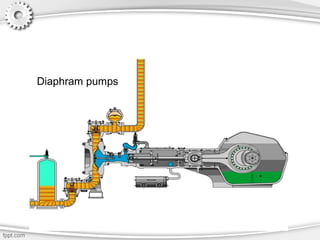

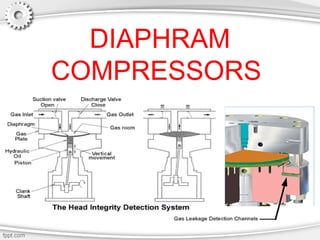

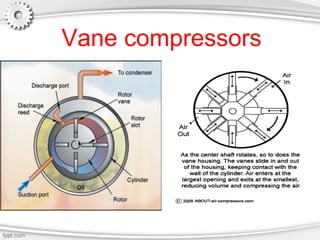

- Positive displacement pumps like gear pumps, vane pumps, piston pumps, and diaphragm pumps.

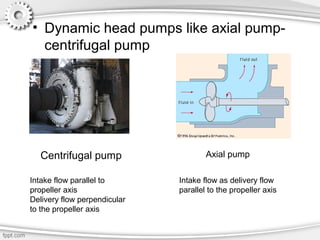

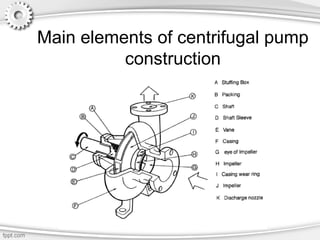

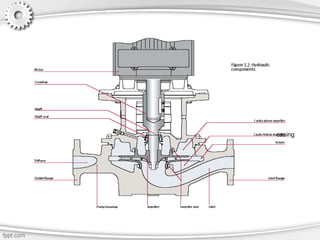

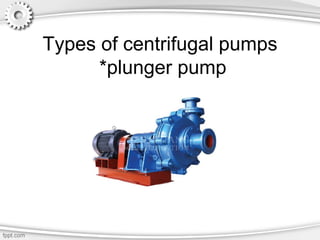

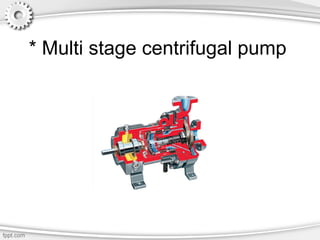

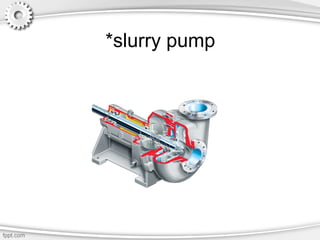

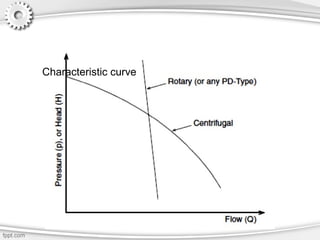

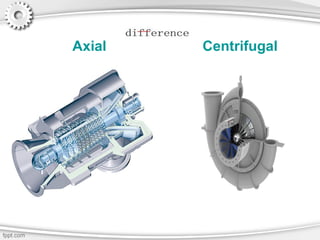

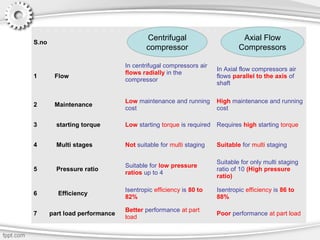

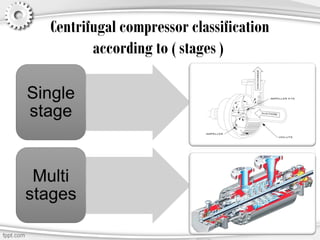

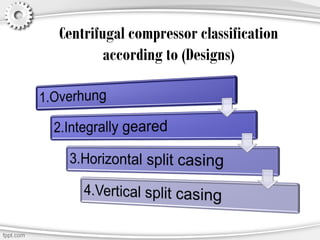

- Dynamic pumps like centrifugal pumps and axial pumps.

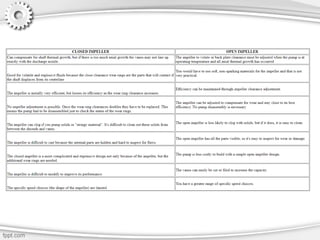

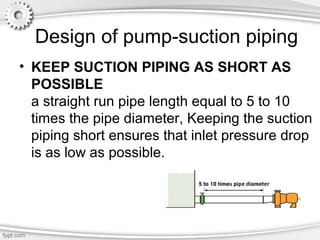

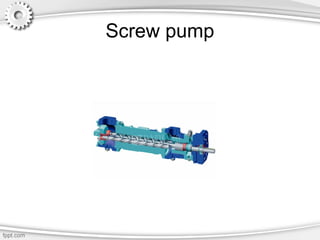

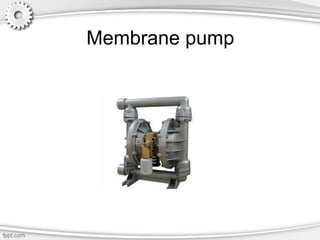

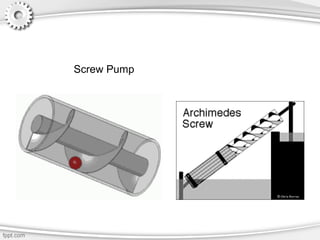

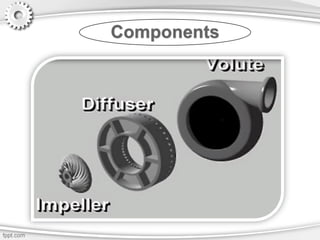

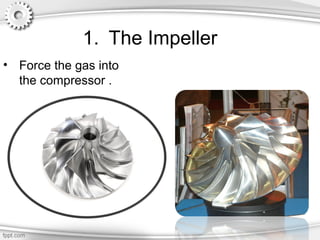

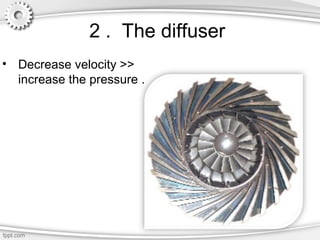

- Details are given on pump components, design considerations for suction piping, and characteristics of specific pump types like centrifugal pumps, screw pumps, and membrane pumps.