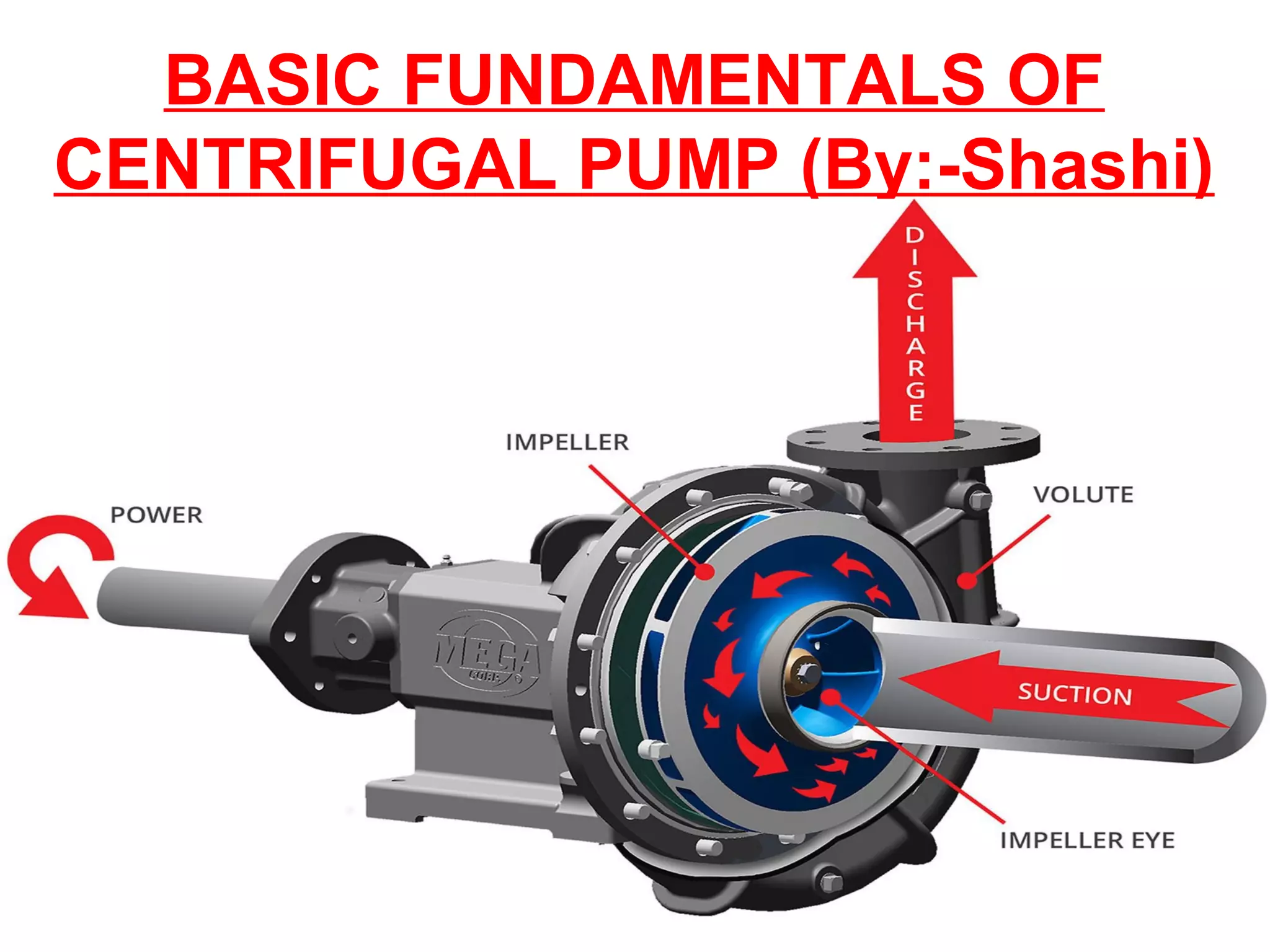

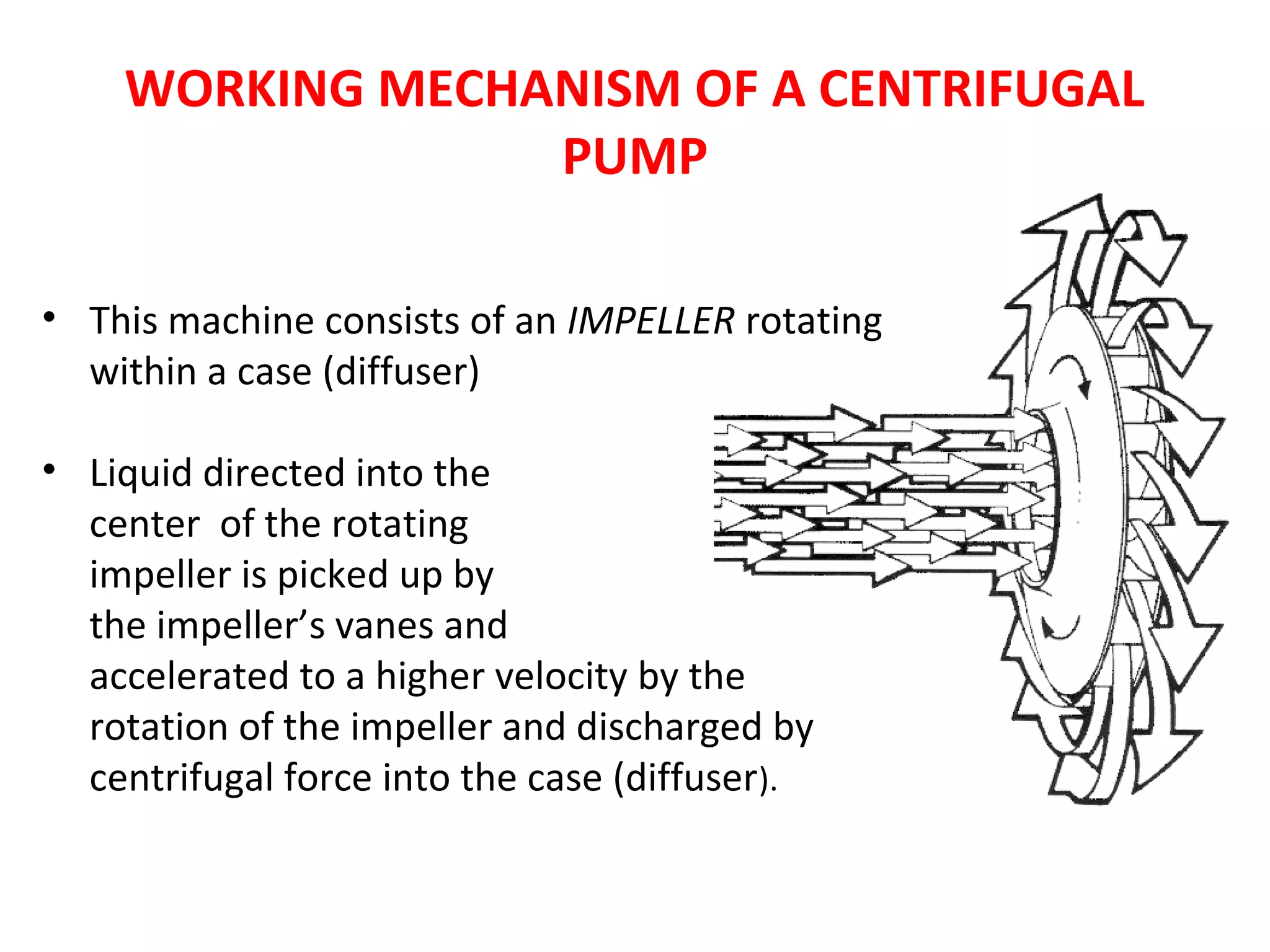

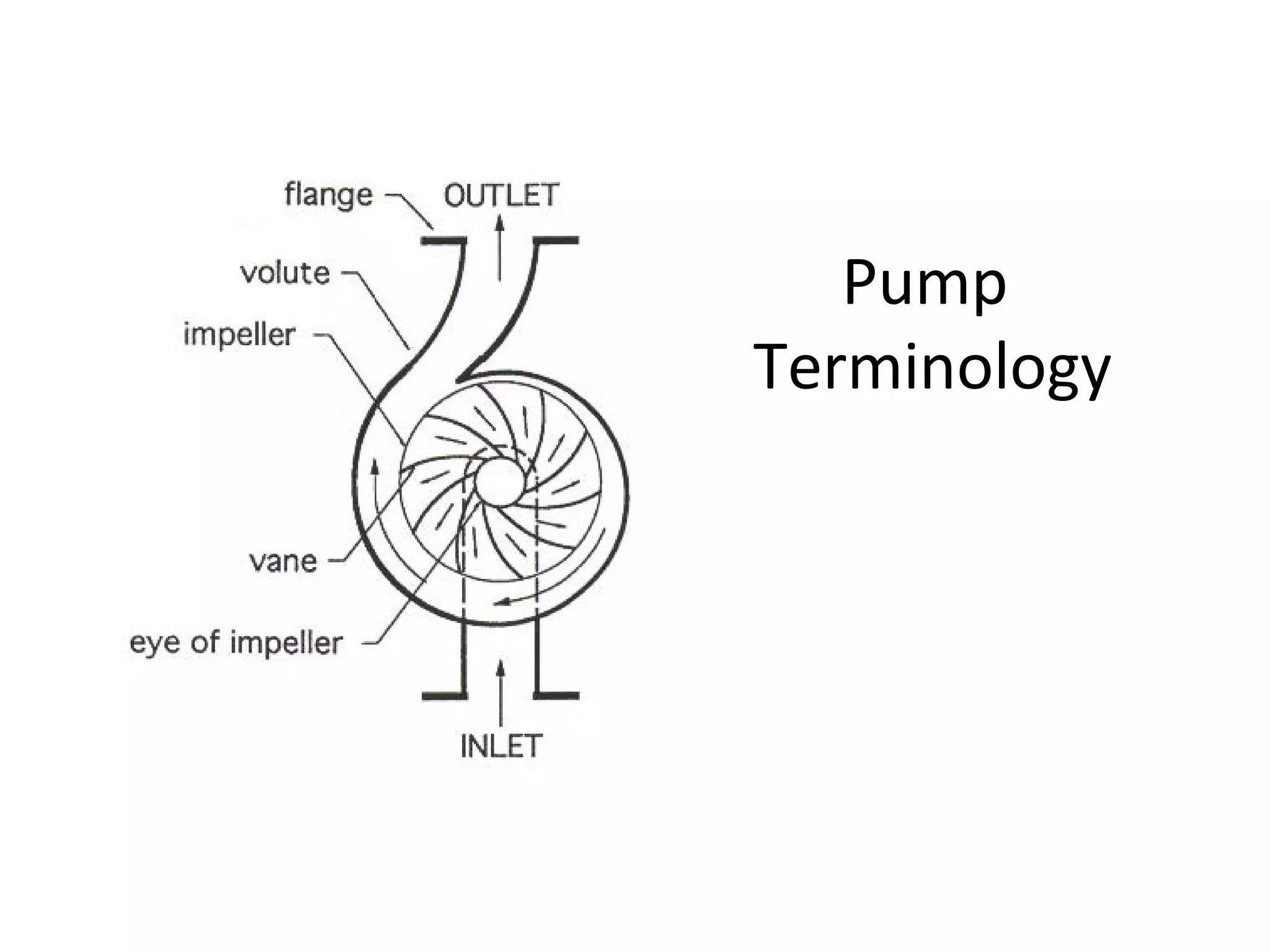

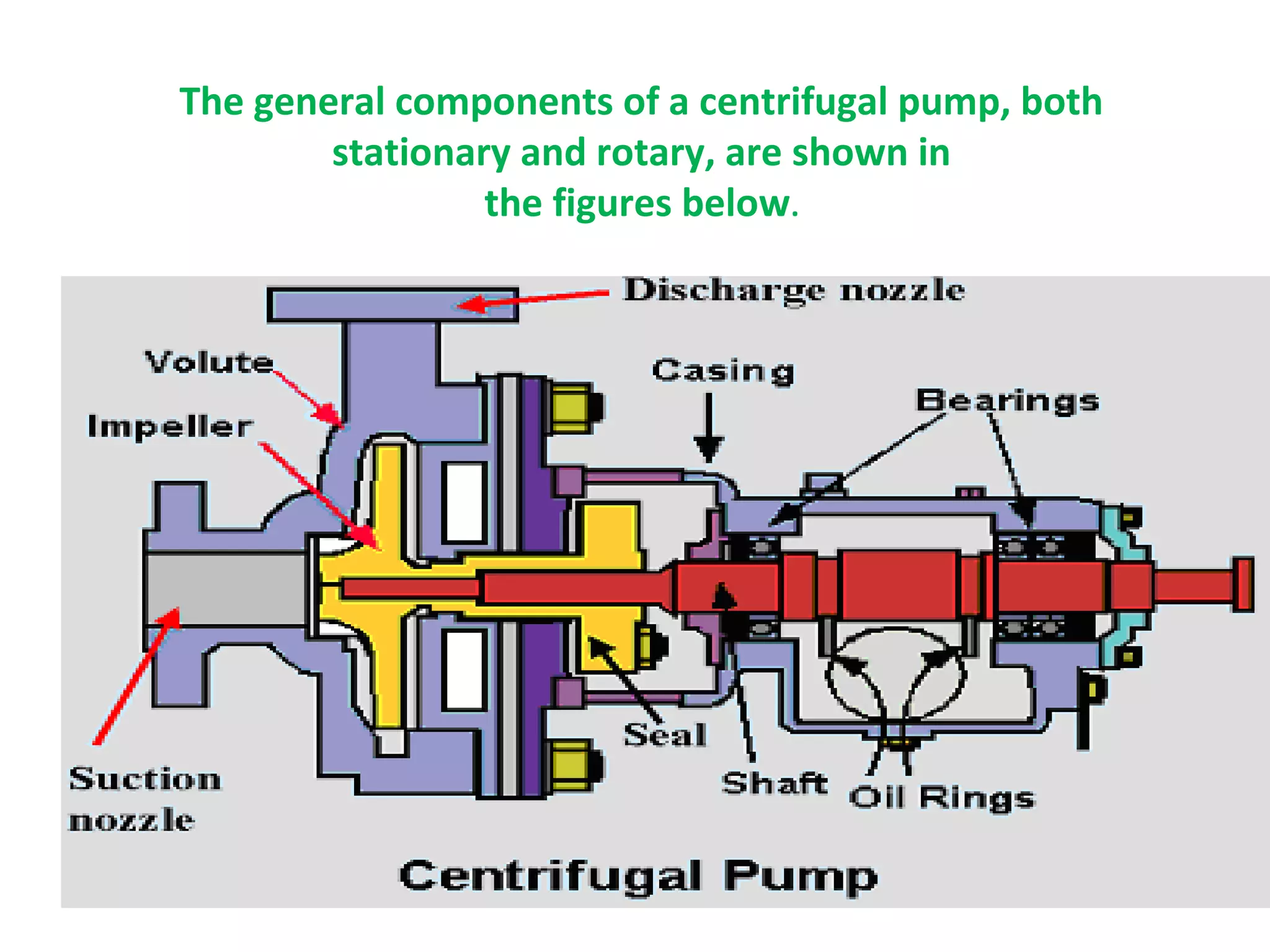

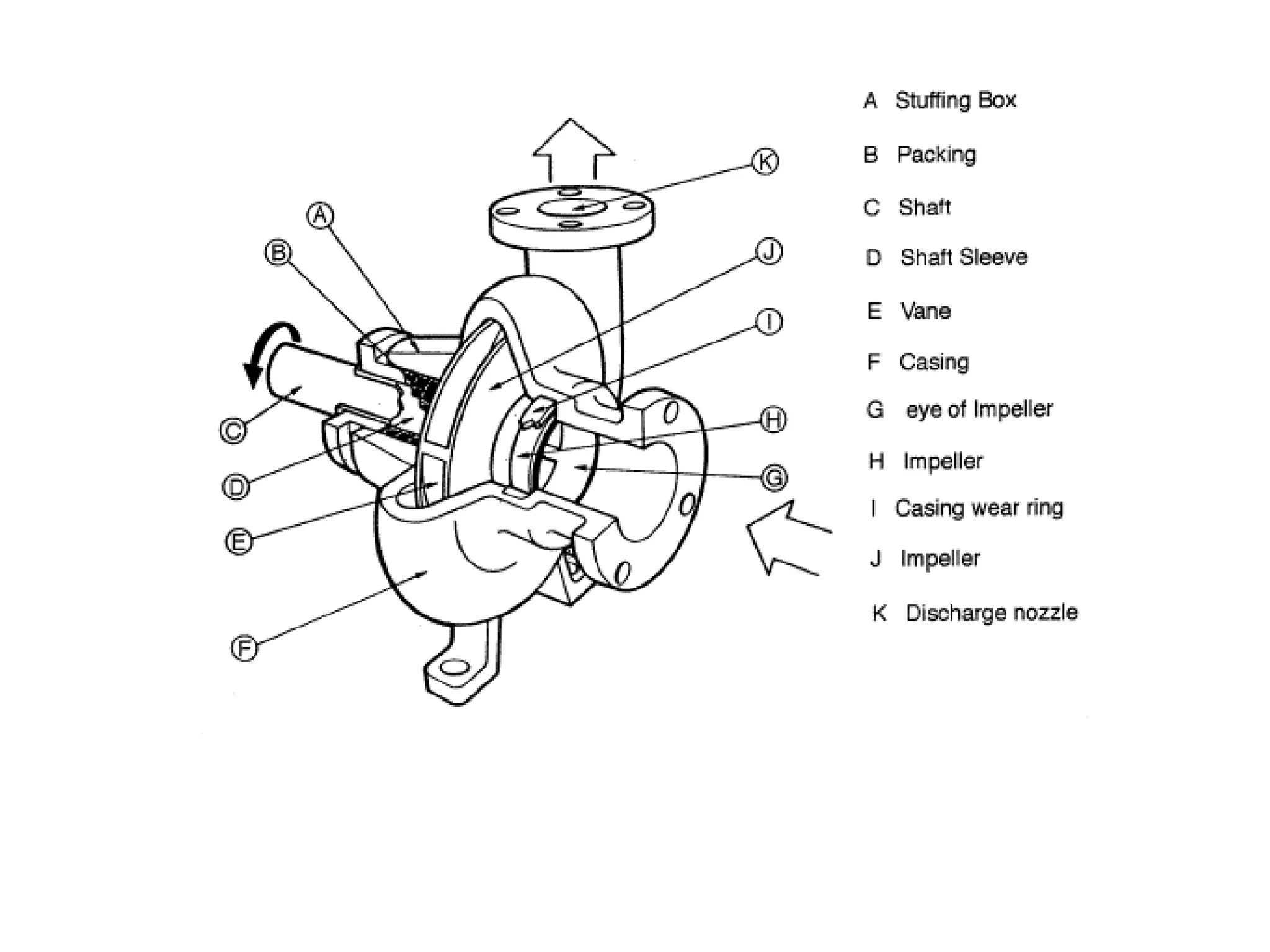

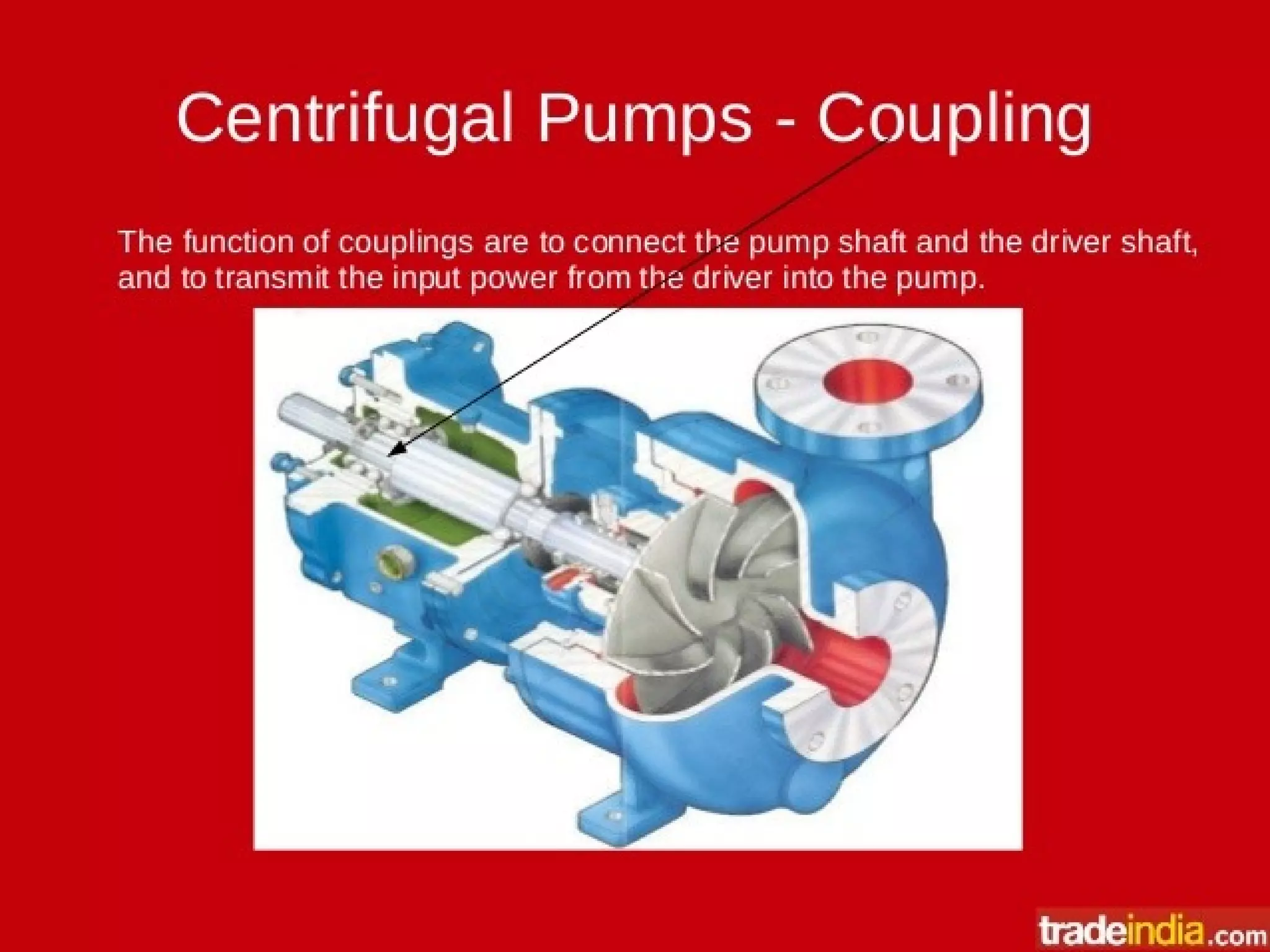

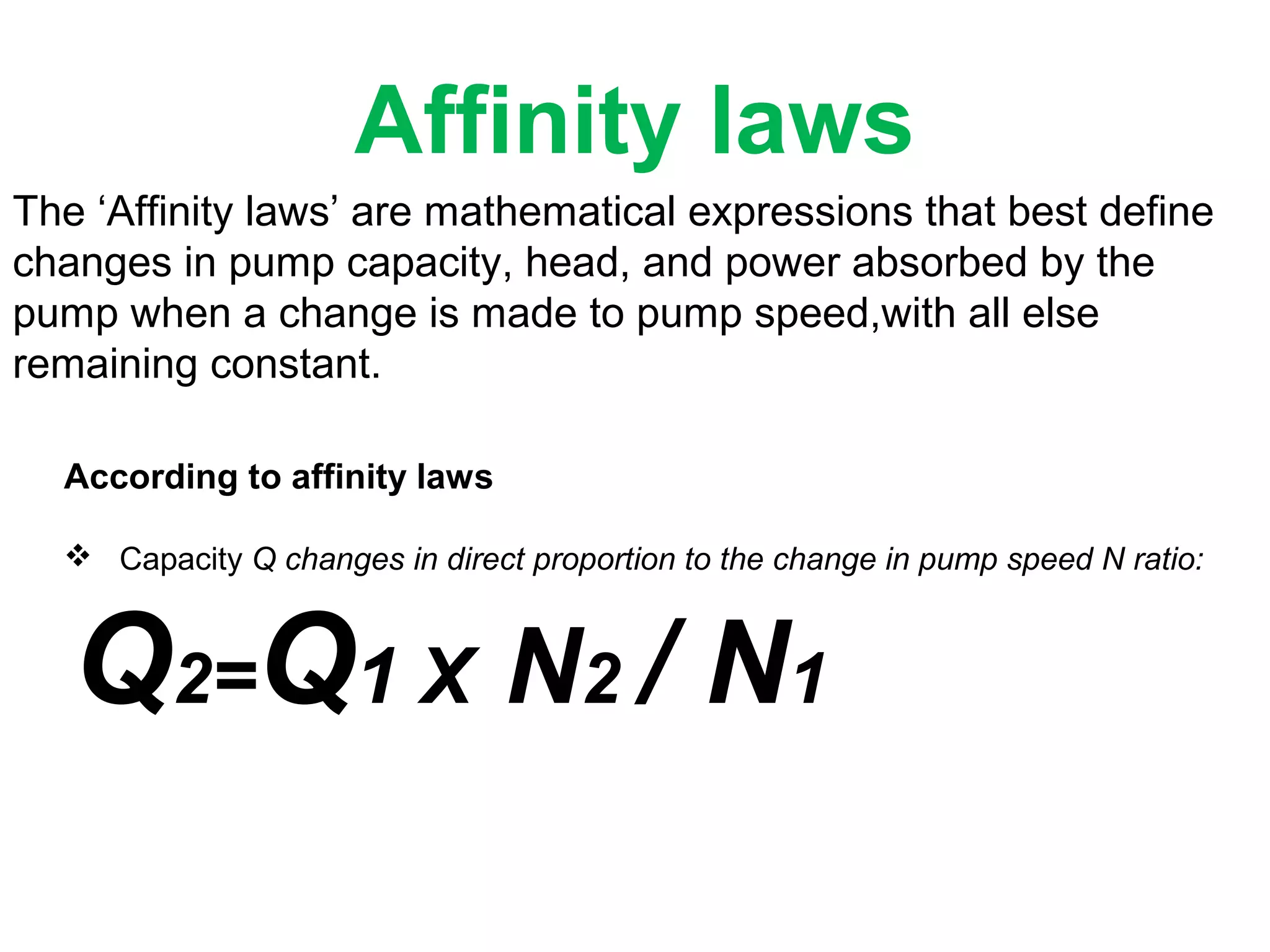

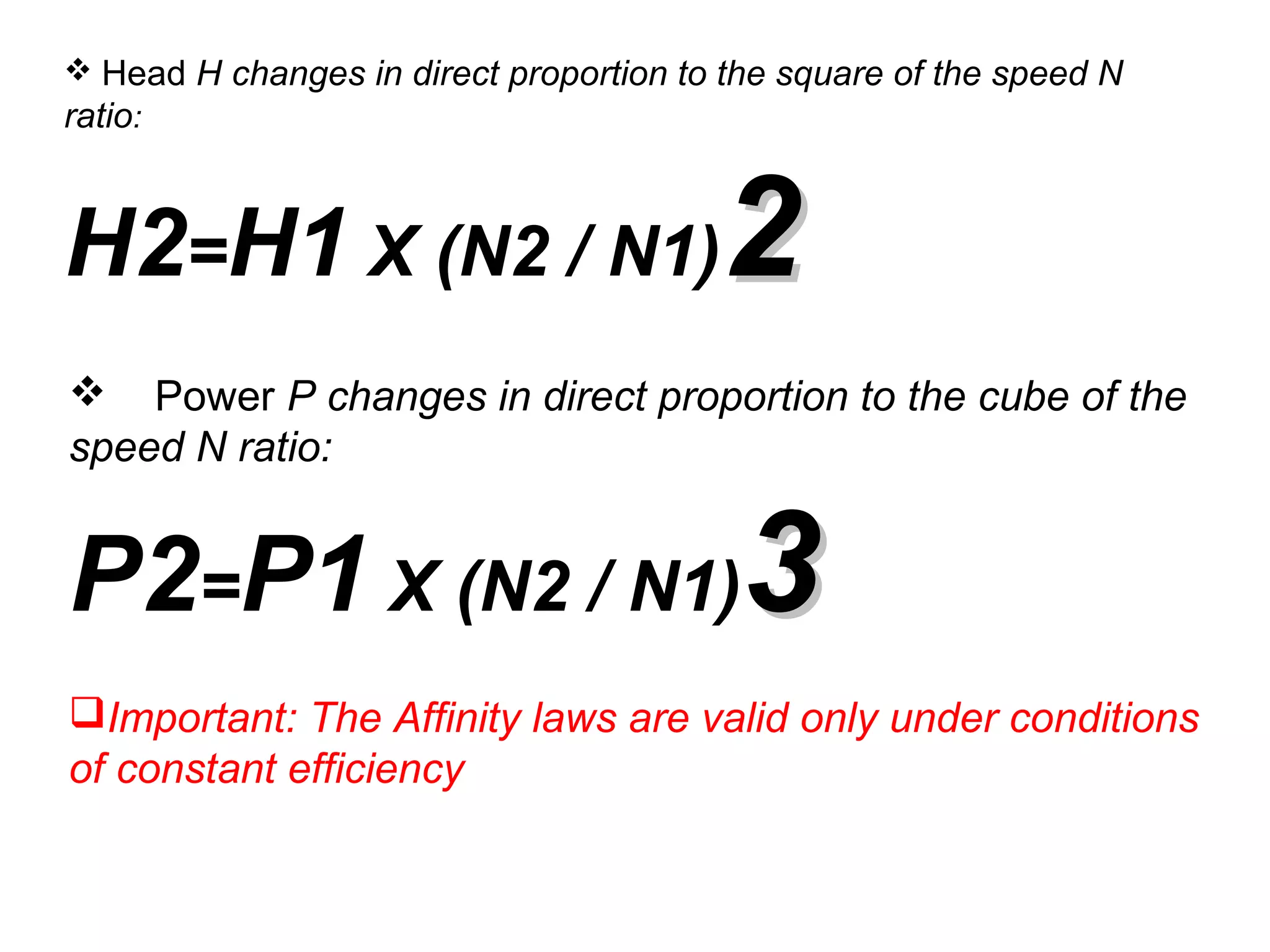

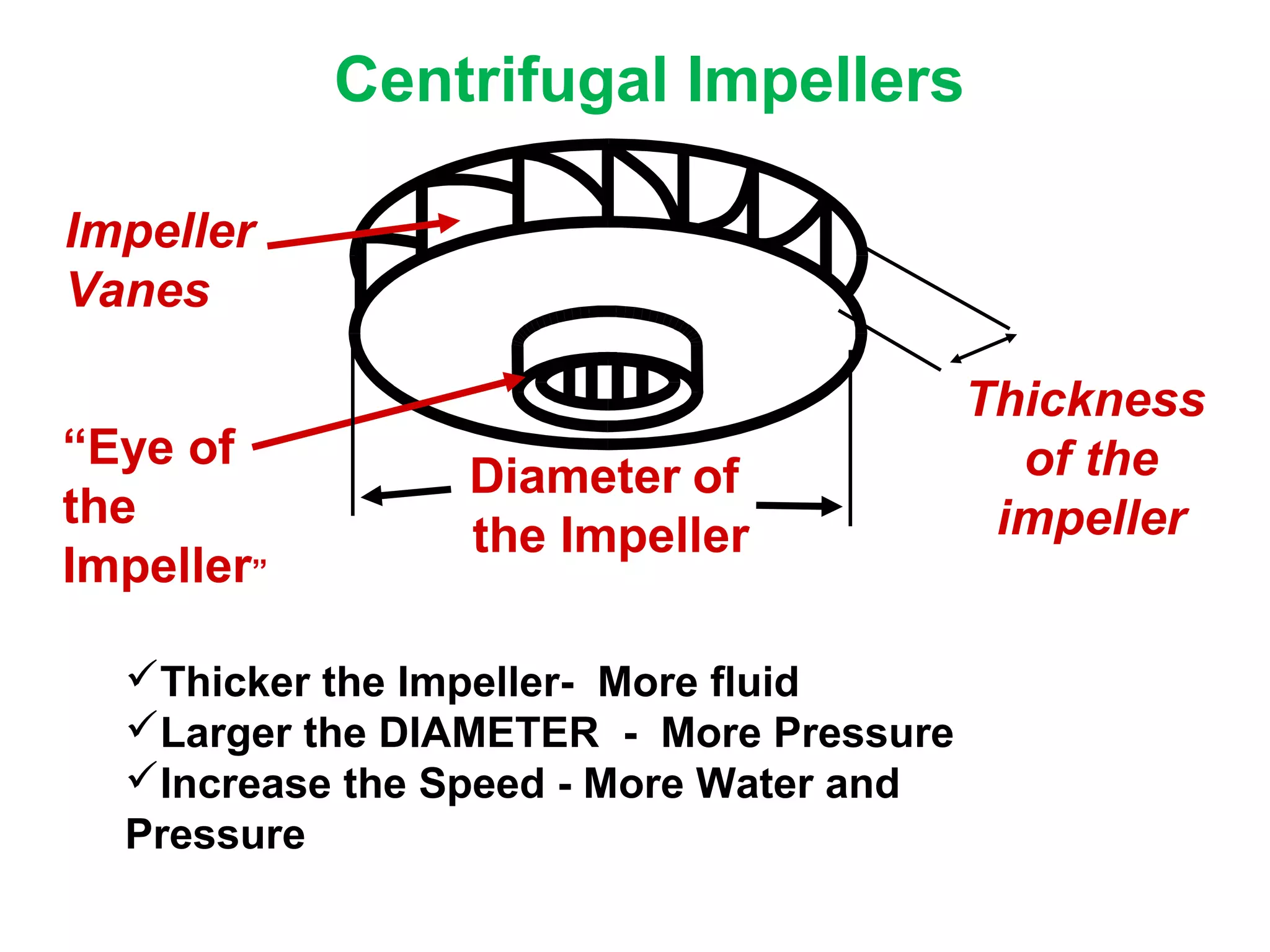

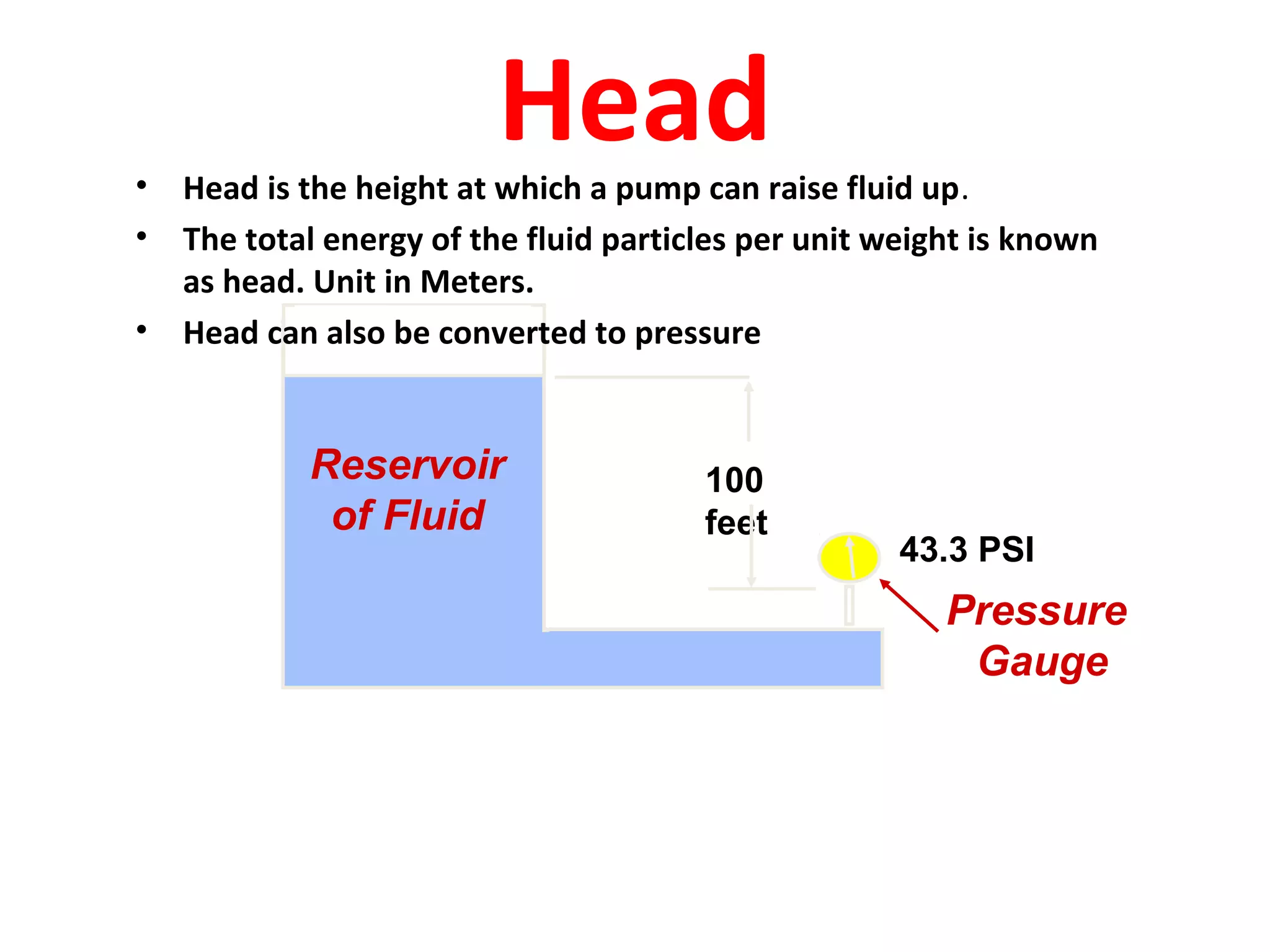

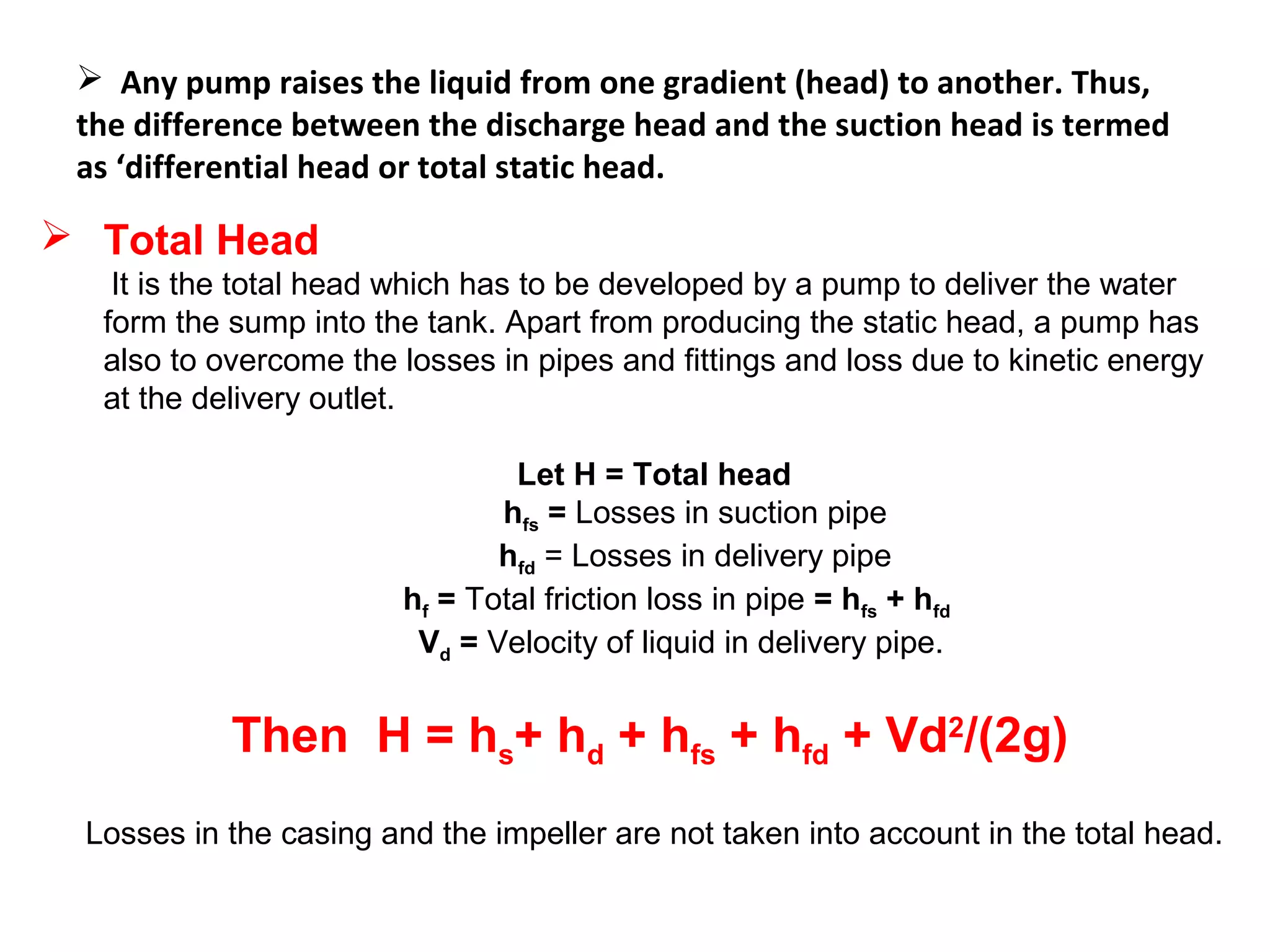

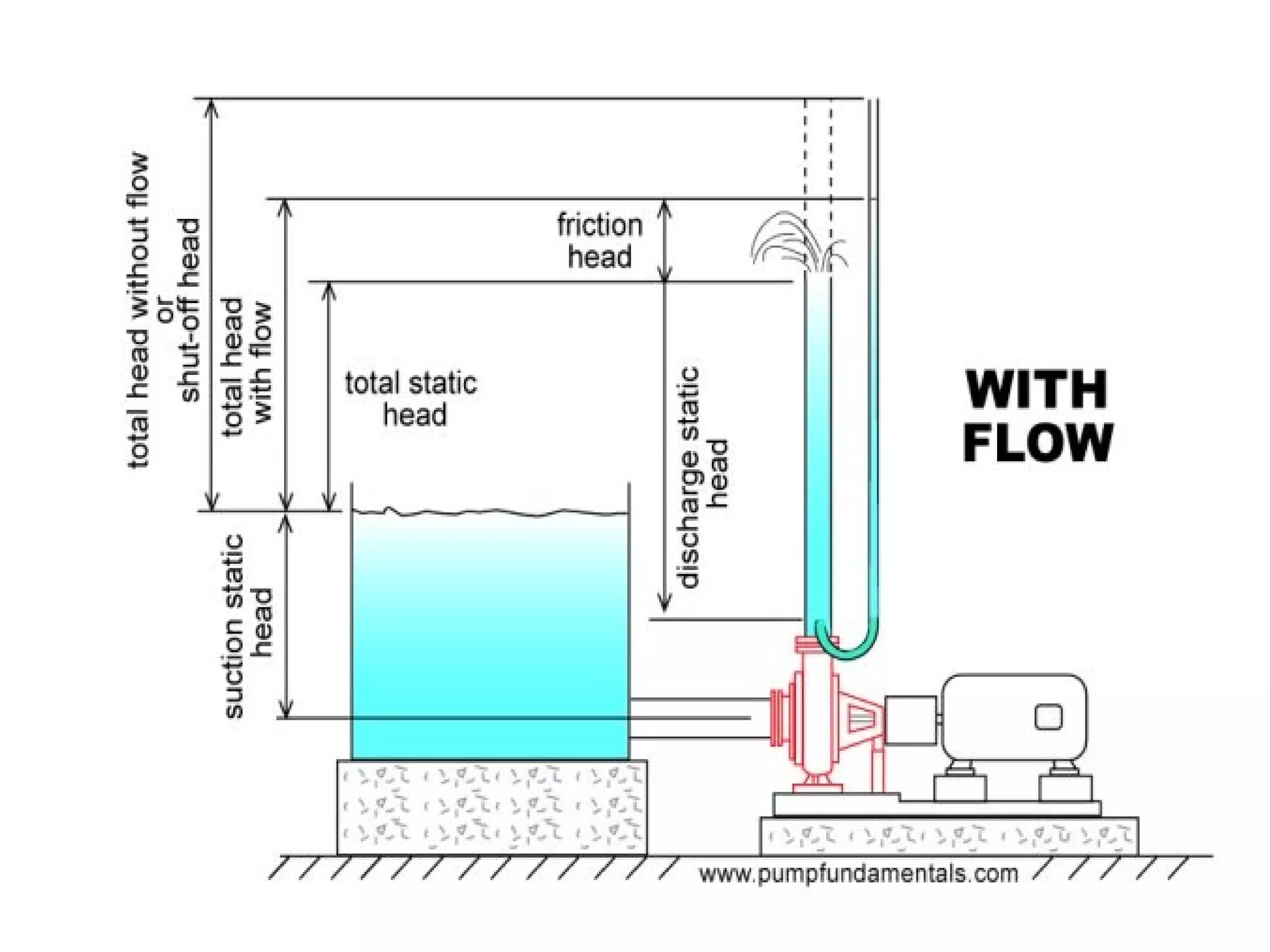

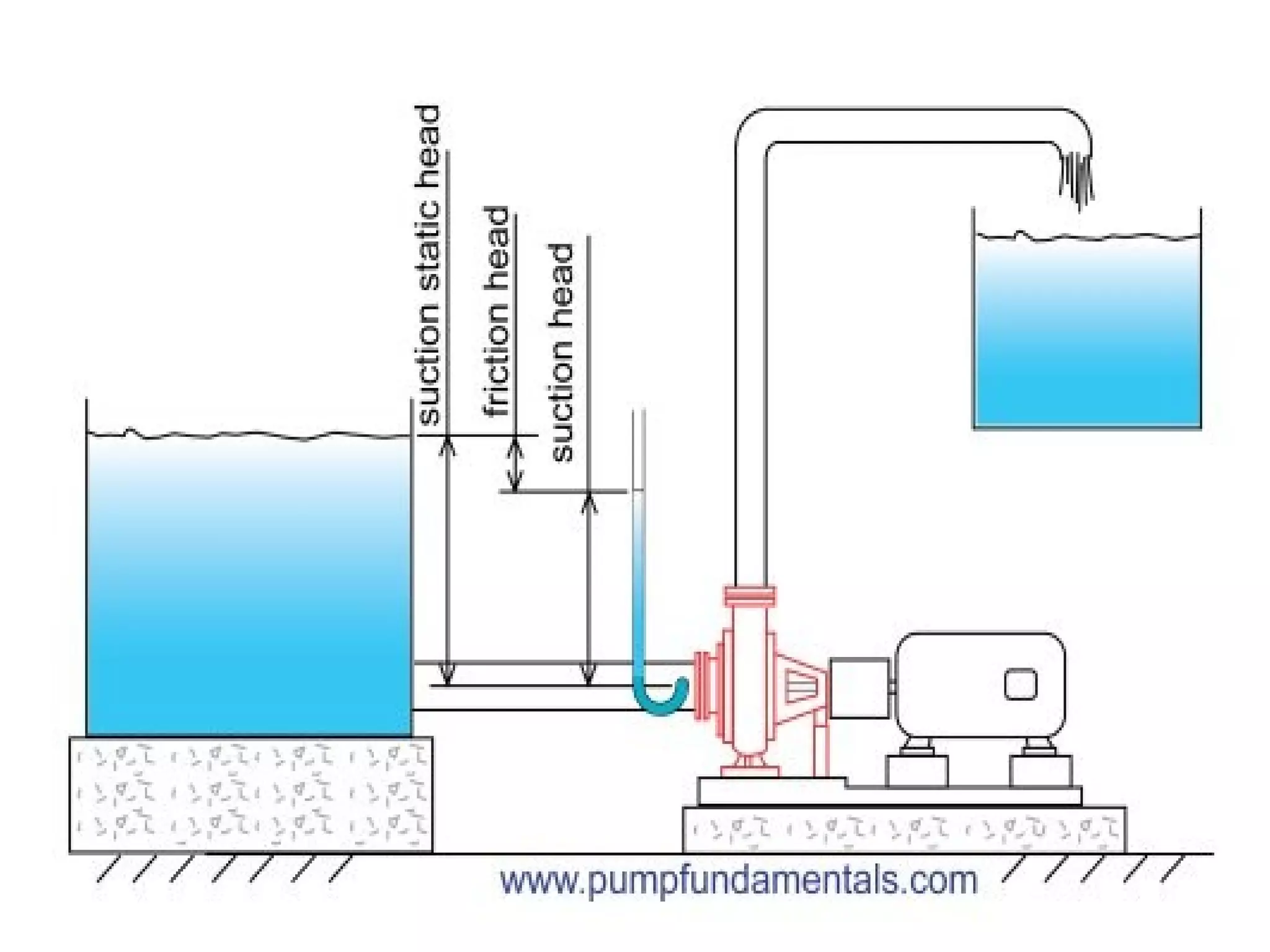

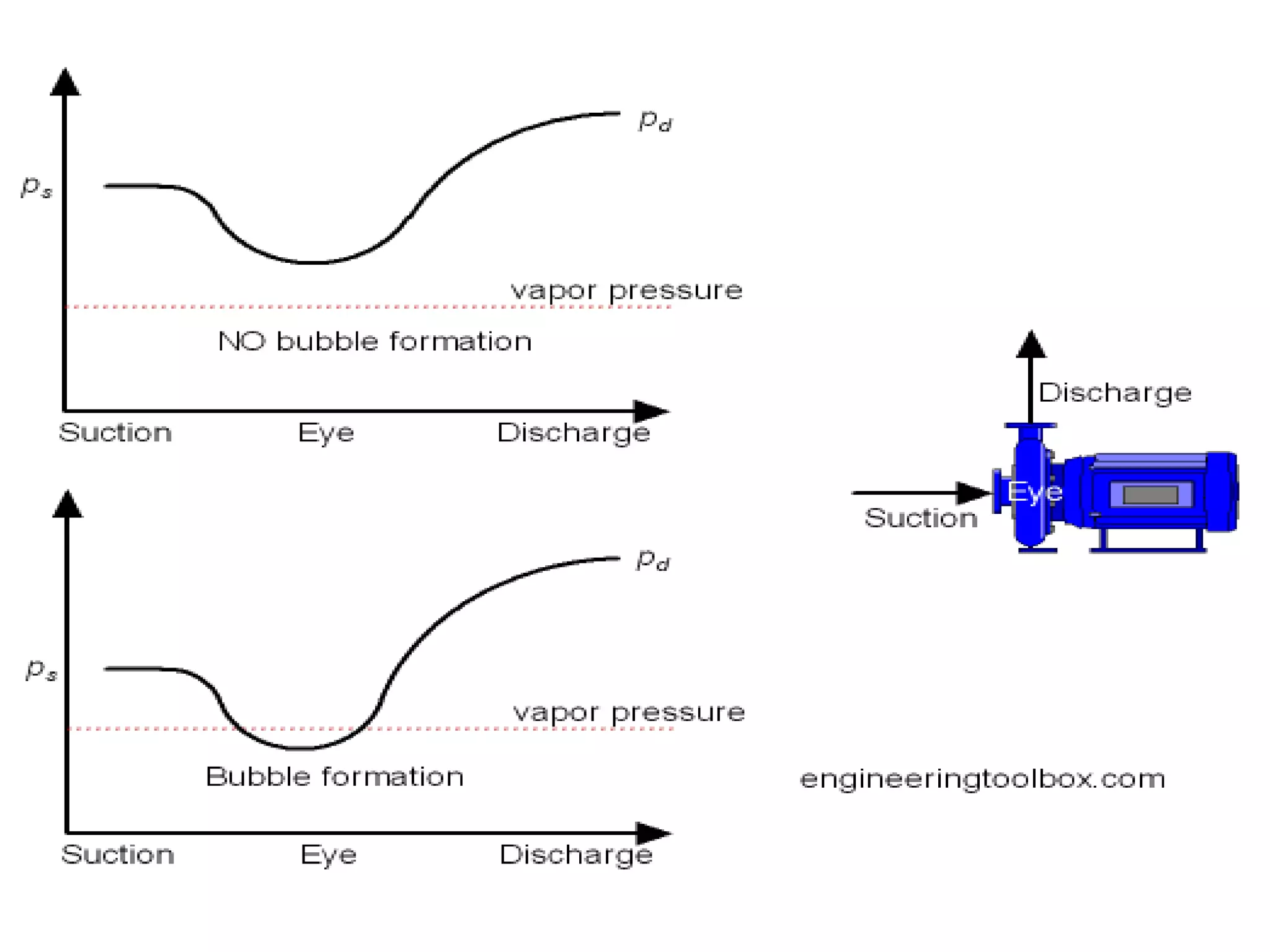

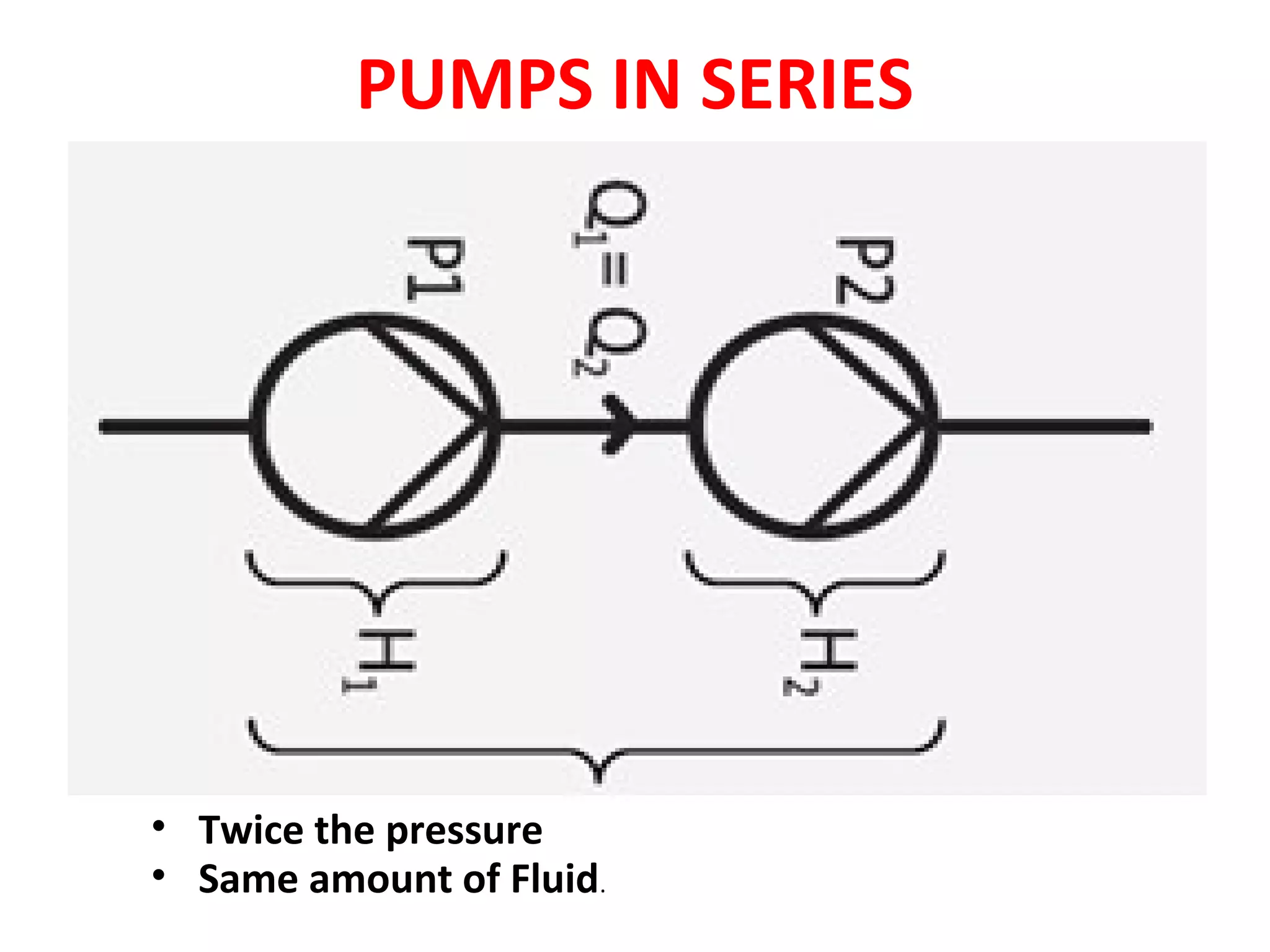

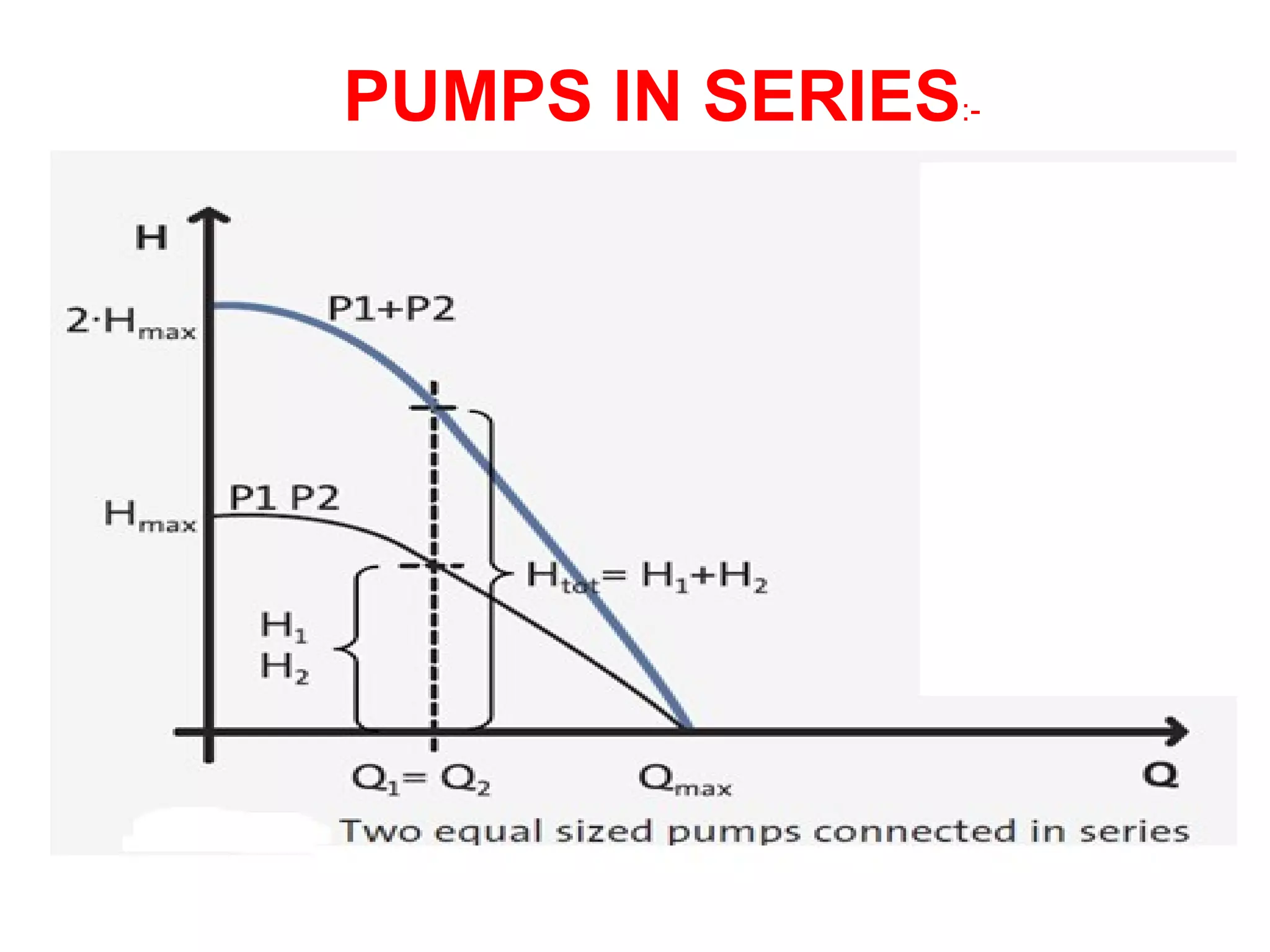

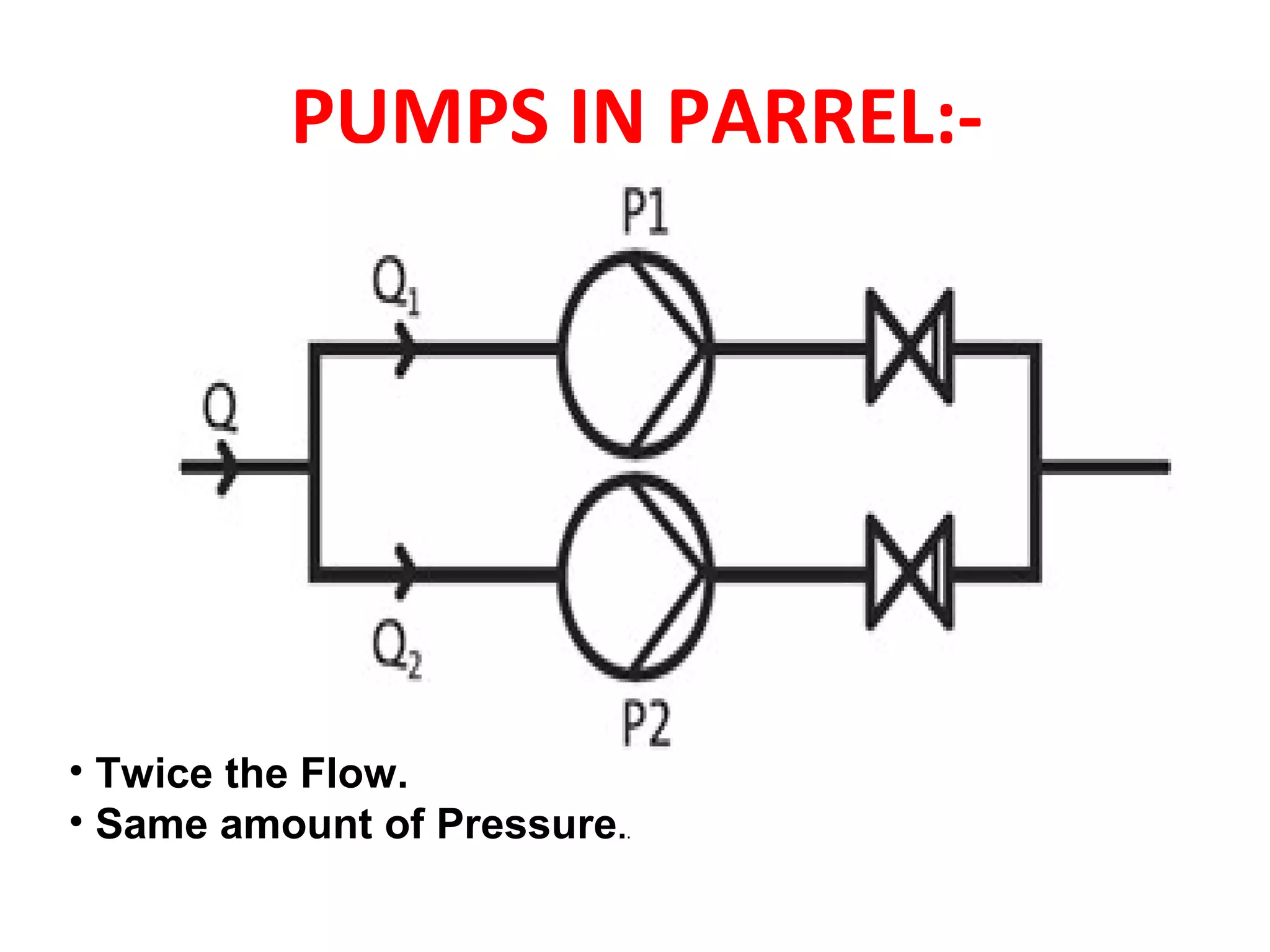

Centrifugal pumps are widely used in petroleum pumping due to their efficiency and simplicity, constituting 80-90% of installed pumps in plants. The document details the operation of centrifugal pumps, emphasizing components like the impeller and casing, working principles, and factors like head and net positive suction head (NPSH) critical for preventing cavitation. It also discusses pump classification and characteristics, including the affinity laws that relate pump speed to capacity, head, and power consumption.