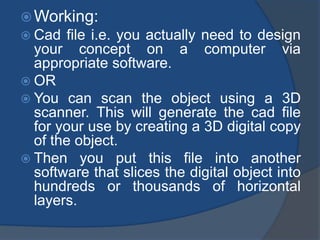

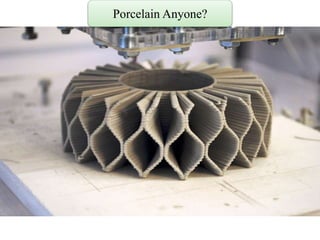

The document discusses 3D printing technologies. It describes how 3D printing works by using digital files to create objects layer by layer through additive manufacturing techniques. Common technologies discussed include fused deposition modeling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Applications mentioned include prototyping, architecture, paleontology, and biotechnology. The document also discusses current research into new 3D printing materials.