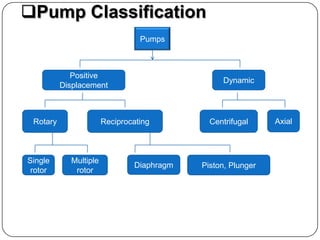

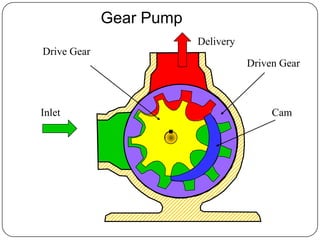

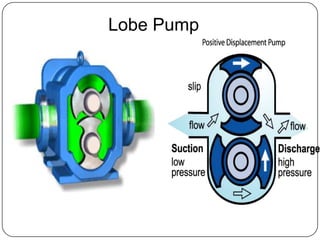

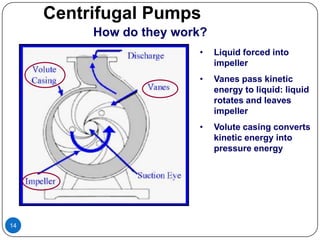

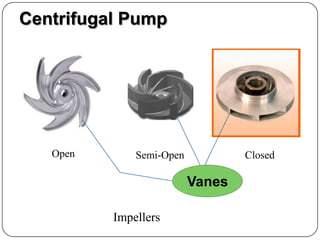

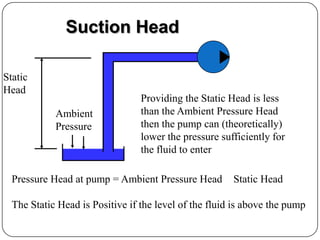

Pumps are devices that use mechanical energy to increase the velocity, pressure, or elevation of liquids and gases. There are two main types of pumps: positive displacement pumps and dynamic pumps. Positive displacement pumps apply direct pressure on a liquid using a reciprocating piston or rotating components. Dynamic pumps use centrifugal force to generate high rotational velocities and convert the kinetic energy of liquids into pressure energy. Common positive displacement pump types include piston pumps, plunger pumps, and diaphragm pumps. Common dynamic pump types include centrifugal pumps which contain an impeller and casing. Proper consideration of factors like net positive suction head are important for pump selection and operation.