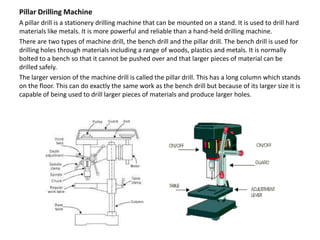

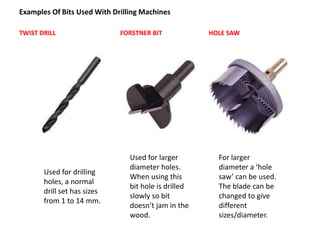

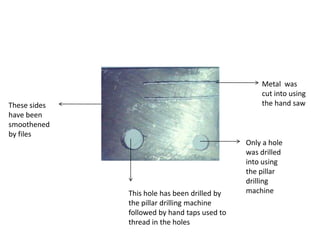

This document provides information about workshop assignments for group members and processes performed in a fitting shop. It discusses types of metals, safety precautions, and various hand tools used such as different types of files for smoothing, making slots, and rounding edges. It also describes machines like pillar drilling machines and bits used for drilling holes of various sizes. Examples of how different tools are used to shape and drill metal are given.