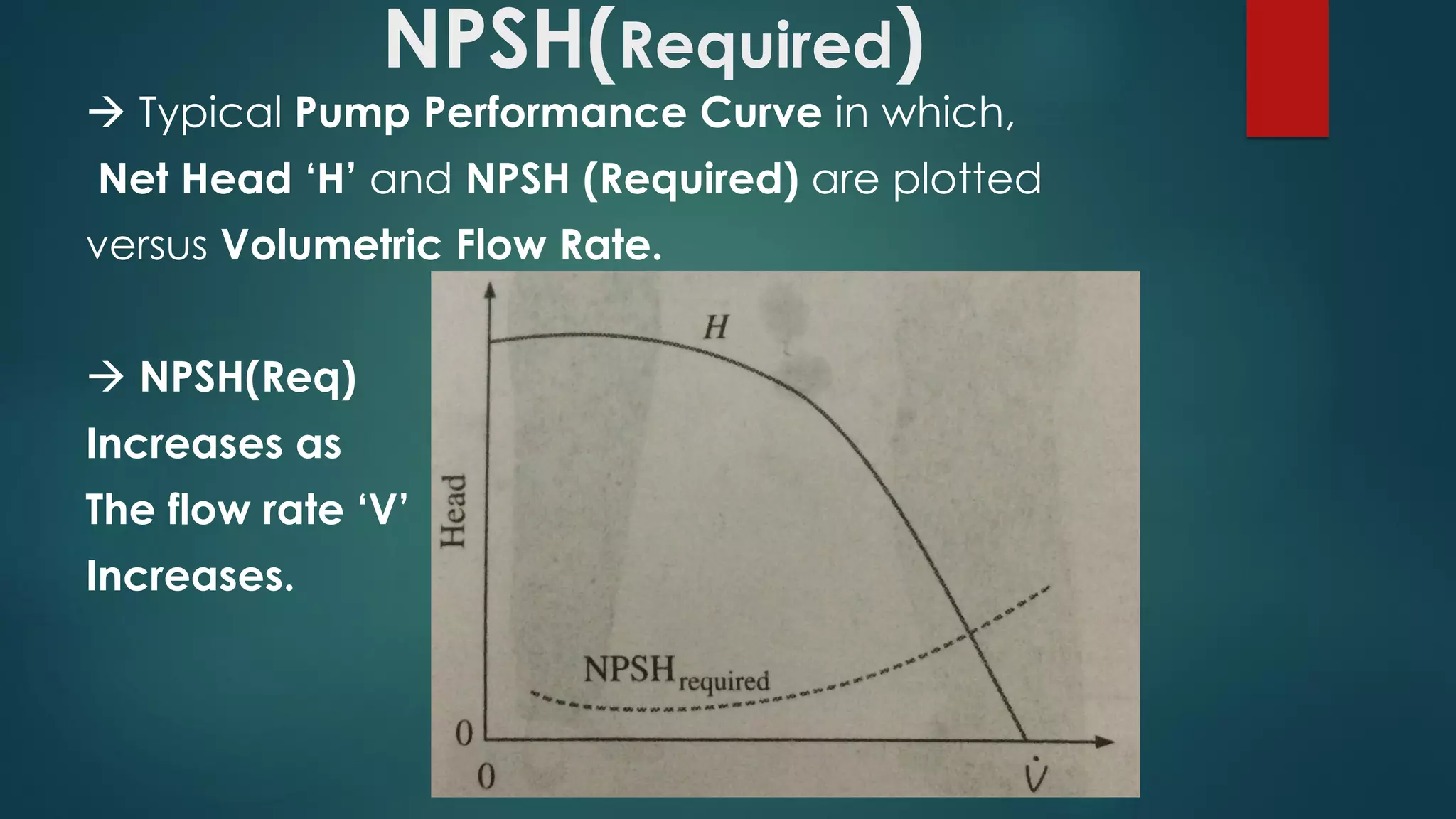

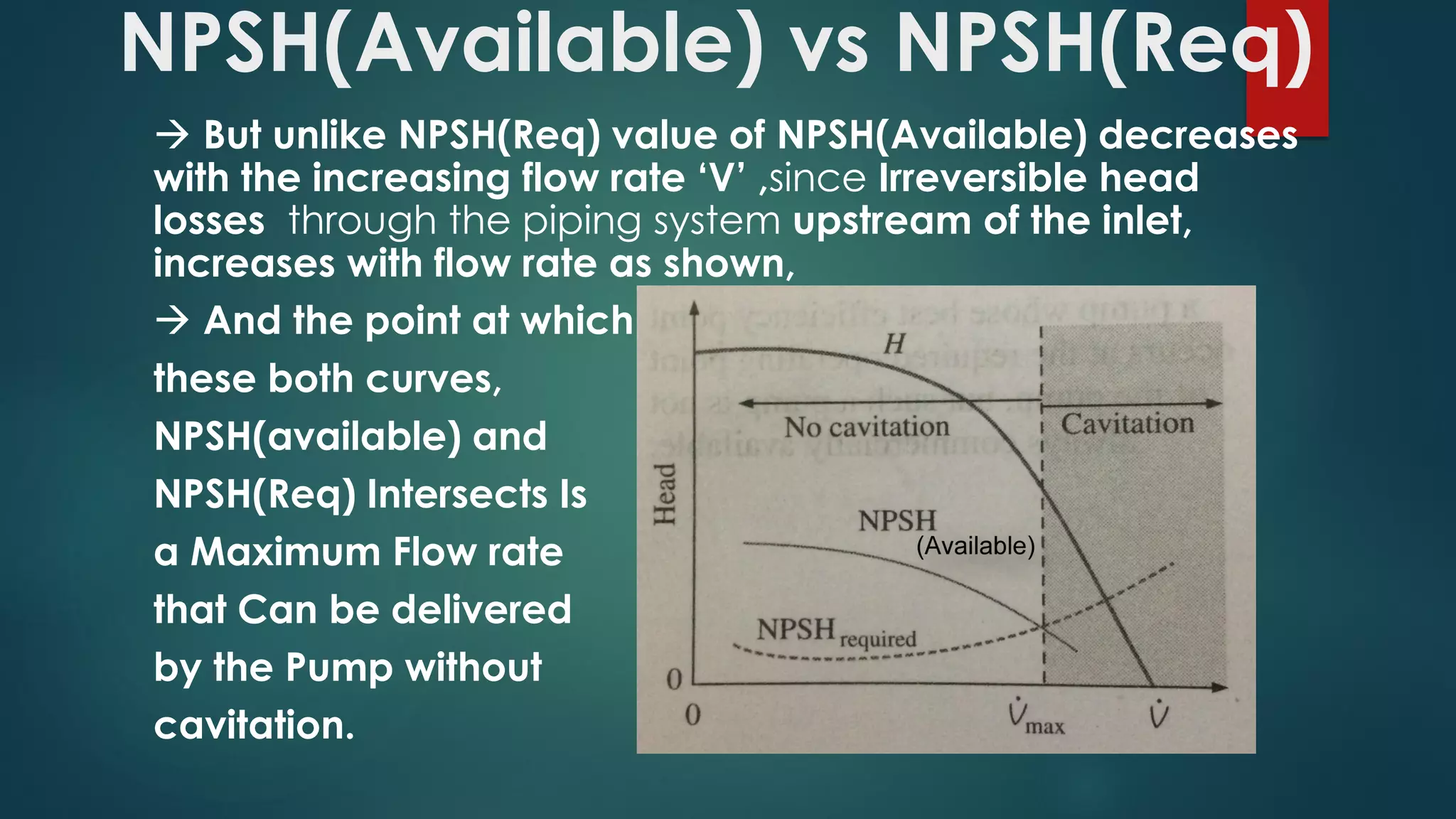

This document summarizes key concepts related to pump cavitation and net positive suction head (NPSH). It defines cavitation as the formation of vapor bubbles when local pressure inside a pump drops below the vapor pressure of the liquid. Repeated cavitation can damage impeller blades through pitting and erosion. NPSH is introduced to quantify the pressure required to avoid cavitation. NPSH available considers the inlet pressure accounting for piping losses, while NPSH required is provided by pump manufacturers as the minimum pressure needed. The document outlines how NPSH available and required values vary with flow rate and other variables like liquid temperature.